Silicon/activated charcoal composite cathode material and preparation method thereof

A technology of negative electrode material and activated carbon, which is applied in the field of silicon/activated carbon composite negative electrode material and its preparation, can solve the problems of high lithium ion diffusion resistance and low porosity of carbon coating layer, achieve good cycle stability and facilitate rapid diffusion , the effect of good charge and discharge rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

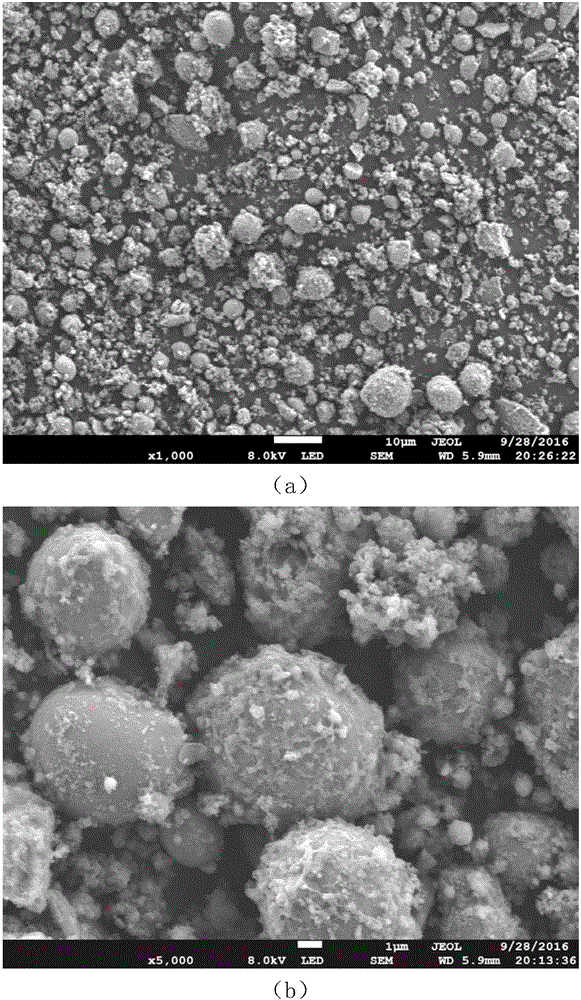

Image

Examples

Embodiment 1

[0036] A silicon / activated carbon composite negative electrode material and a preparation method thereof, is characterized in that it comprises the following steps:

[0037] 1) Disperse 1.395g of nano silicon spheres in 250mL of hydrochloric acid solution to obtain a suspension;

[0038] The pH value of the hydrochloric acid solution is 1;

[0039] 2) Add 1.395 g of dispersant polyvinylpyrrolidone (PVP) to the suspension in step 1) to obtain mixture A;

[0040] 3) adding aniline monomer to the mixture A obtained in step 2) to obtain a mixture B;

[0041] The weight ratio of described aniline monomer and nano silicon sphere is 3: 1;

[0042] 4) Under stirring, ammonium persulfate was added dropwise to mixture B, and after 10 hours of polymerization reaction, the product was filtered, washed, and dried to obtain a silicon / polyaniline composite;

[0043] The ratio of the amount of substance of the ammonium persulfate to the aniline monomer in step 2) is 1:1;

[0044] The temp...

Embodiment 2

[0050] Use the silicon porous carbon composite material that obtains in embodiment 1 to carry out the following steps:

[0051] 1) The silicon porous carbon composite material is mixed with the conductive agent acetylene black and the binder CMC respectively according to the mass ratio of 60:20:20, and the mixture is prepared into a slurry with distilled water, and evenly coated on the copper foil, 60 ℃ Vacuum dried for 8 hours to prepare a pole piece for an experimental battery.

[0052] 2) Lithium sheet is used as the counter electrode, and the electrolyte is 1mol / L (volume ratio is 1:1:1) LiPF 6 / EC+DEC+DMC solution, the diaphragm is Celgard 2400 film, and assembled into a LIR2430 button cell in a glove box filled with an argon atmosphere.

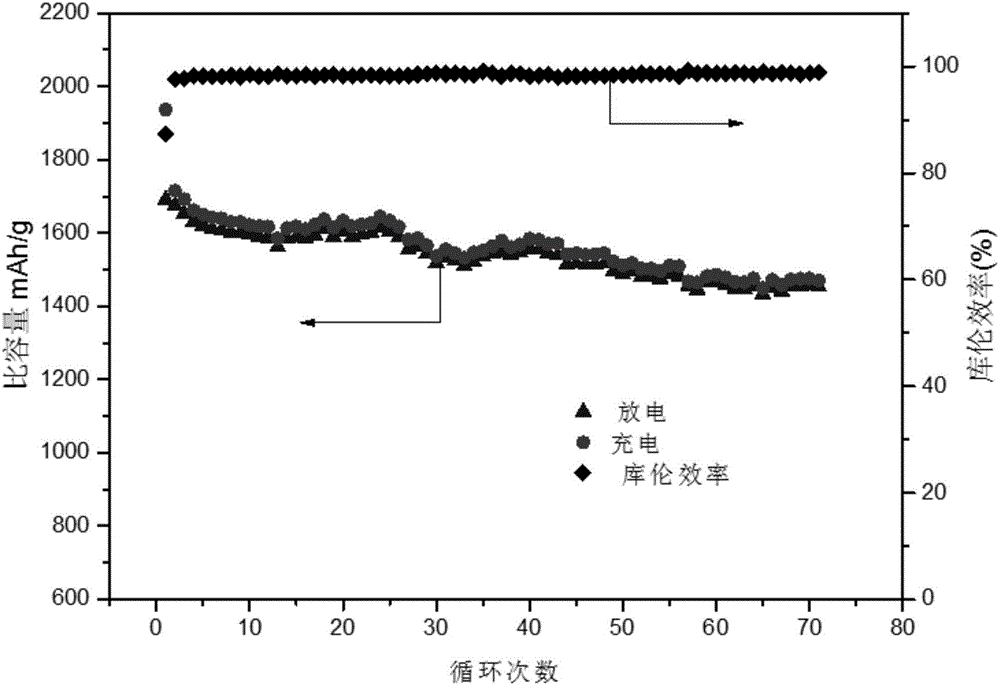

[0053] figure 2 The cycle performance curve of the silicon / activated carbon nanocomposite assembled battery provided in this example.

[0054] According to the silicon / activated carbon composite material prepared under the condition...

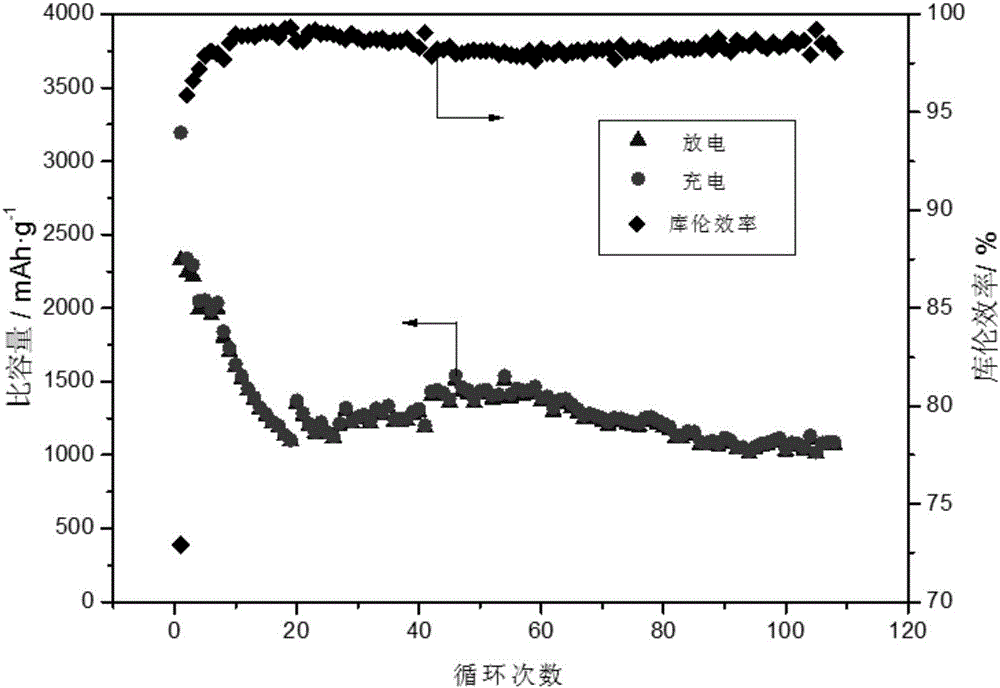

Embodiment 3

[0057] A silicon / activated carbon composite negative electrode material and a preparation method thereof, is characterized in that it comprises the following steps:

[0058] 1) Disperse 1.395g of nano silicon spheres in 250mL of hydrochloric acid solution to obtain a suspension;

[0059] The pH value of the hydrochloric acid solution is 1;

[0060] 2) Add 2.79 g of dispersant Pluronic F127 (Pluronic F127) to the suspension in step 1) to obtain mixture A;

[0061] 3) adding aniline monomer to the mixture A obtained in step 2) to obtain a mixture B;

[0062] The weight ratio of described aniline monomer and nano silicon ball is 4: 1;

[0063] 4) Add ammonium persulfate dropwise to mixture B under stirring, and after 24 hours of polymerization, filter, wash and dry the product to obtain a silicon / polyaniline composite;

[0064] The ratio of the amount of substance of the ammonium persulfate to the aniline monomer in step 2) is 1:1;

[0065] The temperature in the polymerizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com