Regenerated ternary cathode material and preparation method thereof

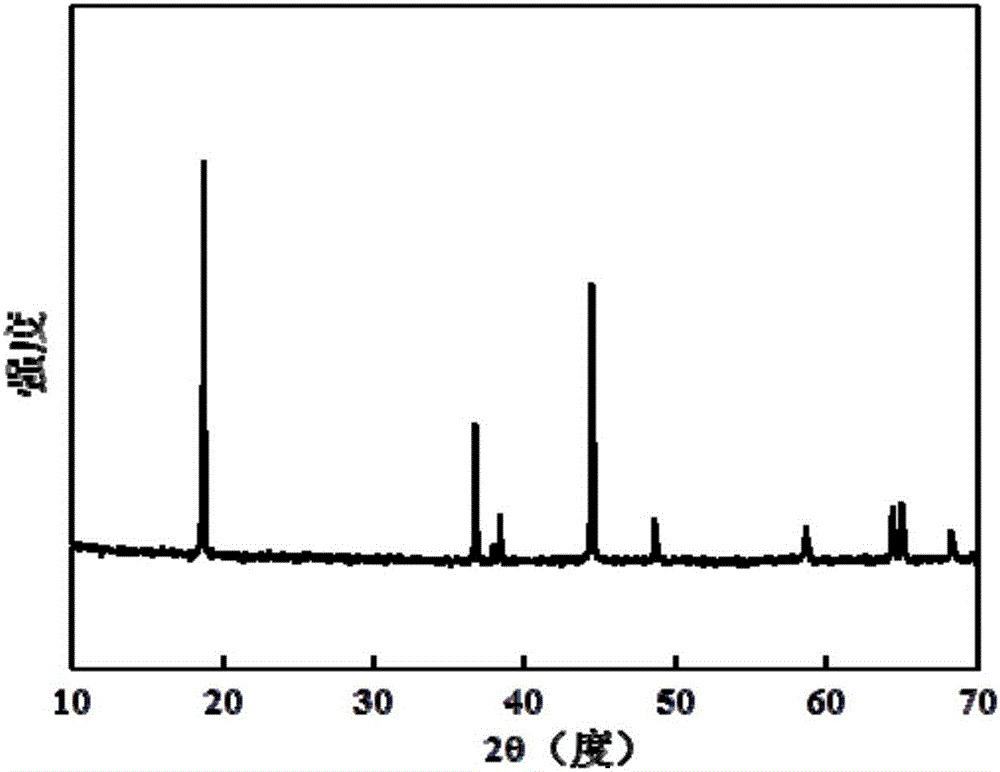

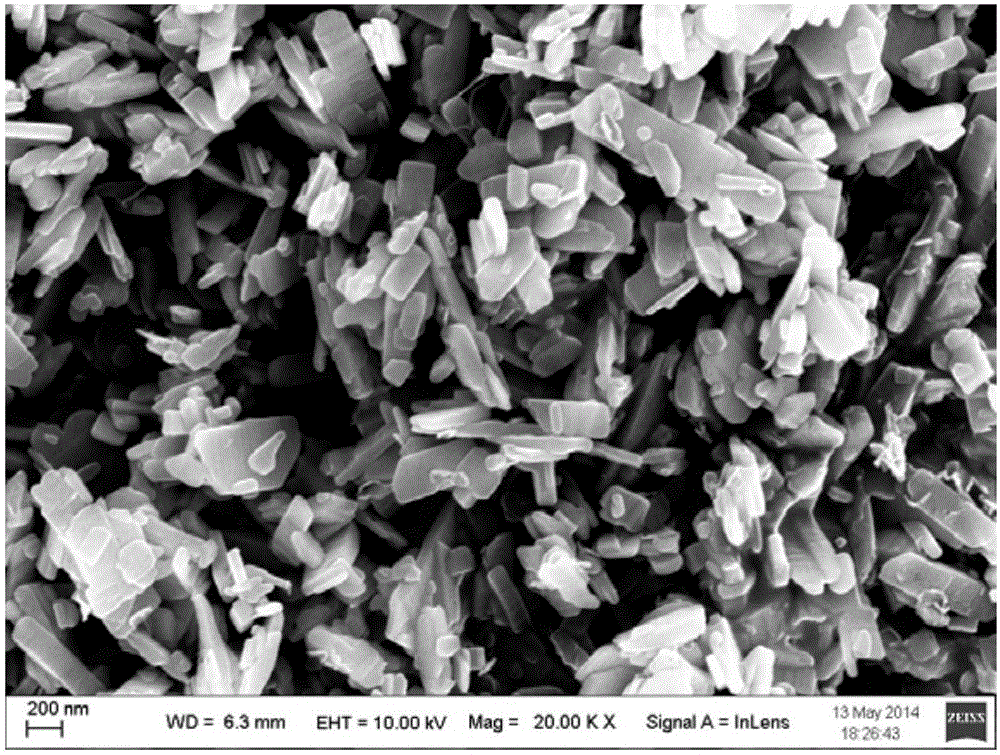

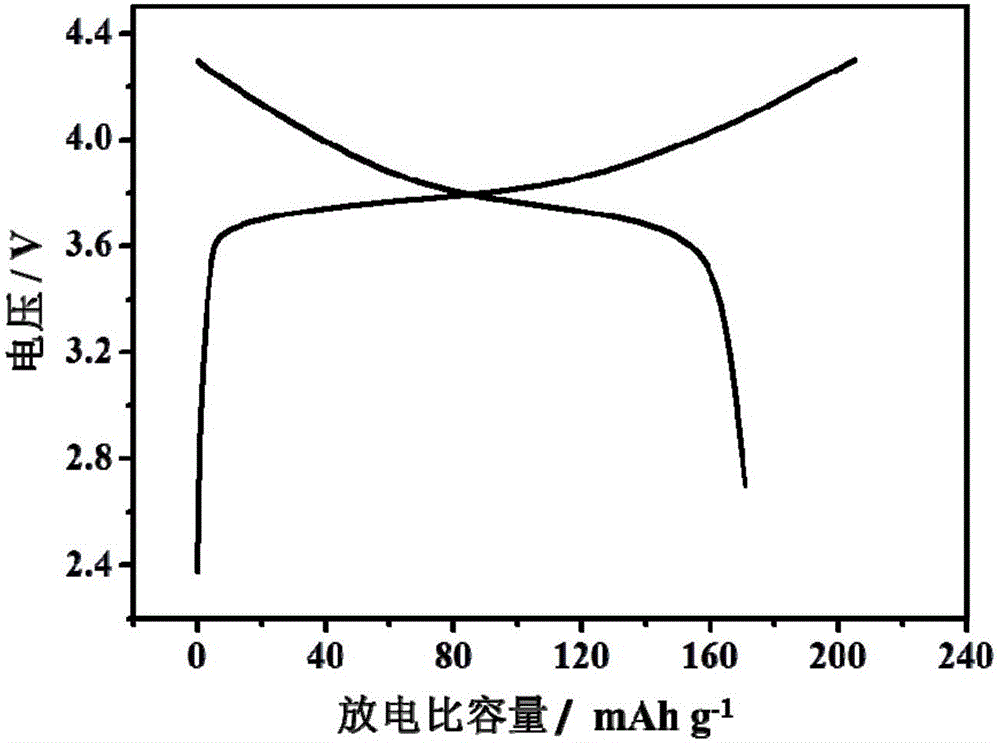

A cathode material and mixed solution technology, which is applied in the field of regenerated ternary cathode materials and its preparation, can solve the problems of synthesis part research, poor electrochemical performance of regenerated ternary cathode materials, etc., and achieve short reaction cycle, excellent electrochemical performance, The effect of short migration distance of lithium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for regenerating a ternary cathode material provided in this embodiment comprises the following steps:

[0051] Step S1, after the waste lithium-ion battery is tested, disassemble the lithium-ion battery in the glove box to obtain the positive electrode sheet, negative electrode sheet and separator, soak the positive electrode sheet in 10% ammonia water for 120min, wash with distilled water and ethanol Afterwards, dry at 120° C. for 10 h in a vacuum oven. The obtained positive electrode sheet was placed in a crucible and treated at 550° C. for 3 h. After shaking, the ternary positive electrode material falls off from the metal aluminum foil, and the deactivated ternary positive electrode material is obtained;

[0052] In step S2, 10 g of the above-mentioned ternary positive electrode material powder is added to 200 ml of acetic acid aqueous solution with a concentration of 3 mol / L, so that the ternary positive electrode material and acetic acid are fully react...

Embodiment 2

[0064] This embodiment provides a method for regenerating a ternary cathode material, comprising the following steps:

[0065] Step S1, after the waste lithium-ion battery is tested, disassemble the lithium-ion battery in the glove box to obtain the positive electrode sheet, negative electrode sheet and separator, soak the positive electrode sheet in 10% ammonia water for 120min, wash with distilled water and ethanol Afterwards, dry at 120° C. for 10 h in a vacuum oven. The obtained positive electrode sheet was placed in a crucible and treated at 650° C. for 6 h. After shaking, the ternary positive electrode material falls off from the metal aluminum foil, and the deactivated ternary positive electrode material is obtained;

[0066] In step S2, take 8 g of the above-mentioned ternary positive electrode material powder and add it to 170 ml of acetic acid aqueous solution with a concentration of 2.5 mol / L, so that the ternary positive electrode material and acetic acid are full...

Embodiment 3

[0074] Step S1, after the waste lithium-ion battery is tested, disassemble the lithium-ion battery in the glove box to obtain the positive electrode sheet, negative electrode sheet and separator, soak the positive electrode sheet in 12% ammonia water for 100min, wash with distilled water and ethanol Afterwards, dry at 120° C. for 10 h in a vacuum oven. The obtained positive electrode sheet was placed in a crucible and treated at 600° C. for 4 h. After shaking, the ternary positive electrode material falls off from the metal aluminum foil, and the deactivated ternary positive electrode material is obtained;

[0075] In step S2, 11 g of the above-mentioned ternary positive electrode material powder is added to 180 ml of acetic acid aqueous solution with a concentration of 2.5 mol / L, and the ternary positive electrode material and acetic acid are fully reacted and filtered to obtain lithium acetate, nickel acetate, and acetic acid. The first mixture of manganese, cobalt acetate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com