Preparation method of titanium dioxide nanoparticles/graphene composite photocatalytic material

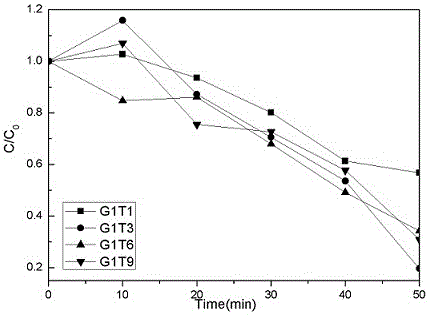

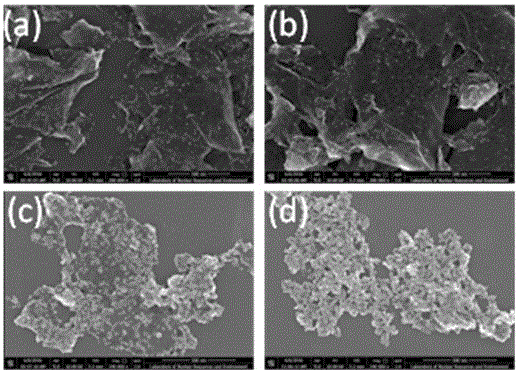

A graphene composite, photocatalytic material technology, applied in the field of photocatalytic composite material preparation, can solve the problems of low light utilization efficiency, limited photocatalytic activity, etc., and achieves broad application prospects, good dispersibility, and controllable particle size effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: After adding 37.5ml of ethanol and 20mg of graphene oxide powder into the beaker to stir and disperse, ultrasonically 1 h to disperse the graphene oxide powder in ethanol evenly. Add 2.5ml of deionized water and 0.3ml of concentrated sulfuric acid, then add 0.085g of tetra-n-butyl titanate dropwise, and stir for 0.5h to obtain a mixed solution;

[0024] Step 2: Transfer the mixed solution to a round bottom flask, reflux at 80° C. for 20 h, and then centrifuge to obtain a precipitate.

[0025] Step 3: Put the precipitate obtained in Step 2 into 40ml of water and 0.8ml of DMF mixed solvent and stir for 30min, transfer the mixed solution into a polytetrafluoroethylene liner, put it into a stainless steel reaction kettle, and keep it warm at 200°C for 16h.

[0026] Step 4: Centrifuge the product obtained after incubation for 10 minutes under the centrifugation condition of 11000 r / min to collect the precipitate, and then wash twice with deionized water and ethanol r...

Embodiment 2

[0028] Step 1: After adding 37.5ml of ethanol and 20mg of graphene oxide powder into the beaker to stir and disperse, ultrasonically 1 h to disperse the graphene oxide powder in ethanol evenly. Add 2.5ml of deionized water and 0.3ml of concentrated sulfuric acid, then add 0.2556g of tetra-n-butyl titanate dropwise, and stir for 0.5h to obtain a mixed solution;

[0029] Steps 2, 3 and 4 are the same as in Example 1. The product is denoted as G1T3.

Embodiment 3

[0031] Step 1: After adding 37.5ml of ethanol and 20mg of graphene oxide powder into the beaker to stir and disperse, ultrasonically 1 h to disperse the graphene oxide powder in ethanol evenly. Add 2.5ml of deionized water and 0.3ml of concentrated sulfuric acid, then add 0.5113g of tetra-n-butyl titanate dropwise, and stir for 0.5h to obtain a mixed solution;

[0032] Steps 2, 3 and 4 are the same as in Example 1. The product is designated as G1T6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com