A kind of partially hydroxylated graphene and preparation method thereof

A hydroxylation and graphene technology, applied in the field of nanomaterials, can solve problems such as difficult dispersion, complex methods, and weak interactions, and achieve the effects of improved electrical conductivity, uniform particle size, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

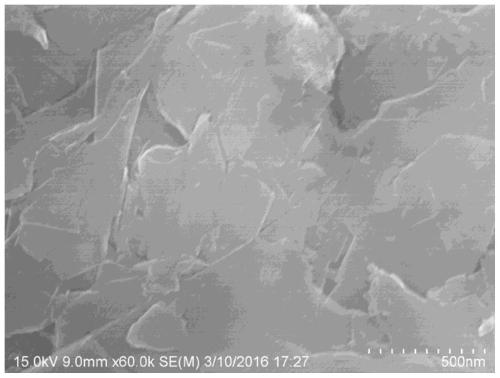

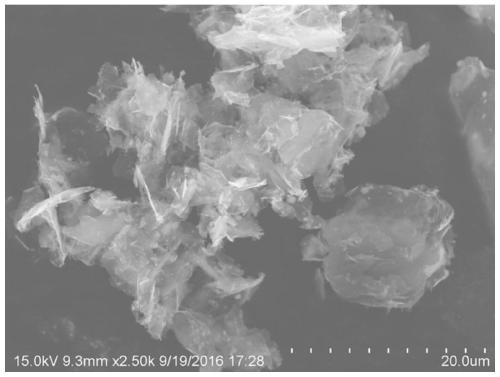

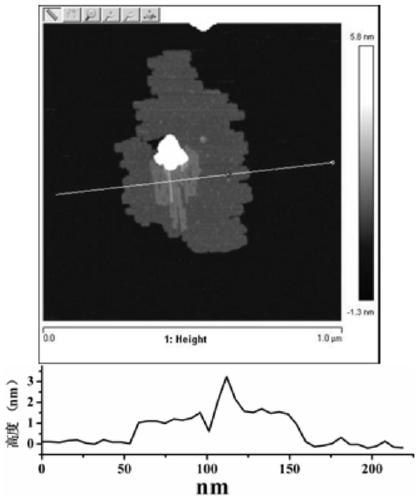

[0036] A preparation method of partially hydroxylated graphene, the steps are as follows:

[0037] Measure 30% hydrogen peroxide and 98% concentrated sulfuric acid with a volume ratio of 1:3, then slowly pour the above hydrogen peroxide into concentrated sulfuric acid in an ice-water bath environment, and continuously stir until uniform, then cool to room temperature to obtain Reaction solution; the reaction solution is added to a ball mill jar, and graphite nanosheets with a thickness of 10 to 100 nm are added thereto, wherein the mixing ratio of the graphite nanosheets and the reaction solution is to add 0.8 mg graphite nanosheets per milliliter of the reaction solution to carry out Ball milling, the ball milling speed is 100rpm, the ball milling time is 4h, and the reaction product is obtained; the reaction product is slowly poured into a large amount of deionized water for dilution, and the process is continuously stirred to speed up heat dissipation, and then neutralized t...

Embodiment 2

[0043] A preparation method of partially hydroxylated graphene, the steps are as follows:

[0044]Measure 30% hydrogen peroxide and 98% concentrated sulfuric acid with a volume ratio of 3:7, then slowly pour the above-mentioned concentrated sulfuric acid into hydrogen peroxide in an ice-water bath environment, and continuously stir until uniform, and then cool to room temperature to obtain Reaction solution; the reaction solution is added to a ball mill jar, and graphite nanosheets with a thickness of 10 to 100 nm are added thereto, wherein the mixing ratio of the graphite nanosheets and the reaction solution is to add 0.9 mg graphite nanosheets per milliliter of the reaction solution to carry out Ball milling, the ball milling speed is 150rpm, the ball milling time is 4h, and the reaction product is obtained; the reaction product is slowly poured into a large amount of deionized water for dilution, and the process is continuously stirred to speed up heat dissipation, and then ...

Embodiment 3

[0048] A preparation method of partially hydroxylated graphene, the steps are as follows:

[0049] Measure 30% hydrogen peroxide and 98% concentrated sulfuric acid with a volume ratio of 1:3, then slowly pour the above-mentioned concentrated sulfuric acid into hydrogen peroxide in an ice-water bath environment, and continuously stir until uniform, and then cool to room temperature to obtain Reaction solution; the reaction solution is added to a ball mill jar, and graphite nanosheets with a thickness of 10 to 100 nm are added thereto, wherein the mixing ratio of the graphite nanosheets and the reaction solution is to add 1.0 mg of graphite nanosheets per milliliter of the reaction solution to carry out Ball milling, the ball milling speed is 250rpm, the ball milling time is 4h, and the reaction product is obtained; the reaction product is slowly poured into a large amount of deionized water for dilution, and the process is continuously stirred to speed up heat dissipation, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com