Selenium-enriched weight-losing meal replacement powder and production method thereof

A meal replacement powder and selenium-enriched technology, which is applied in food science and other fields, can solve problems such as unsatisfactory results, and achieve the effect of slowing down the digestion speed and cleaning the digestive system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

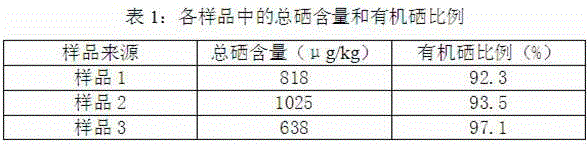

Image

Examples

Embodiment 1

[0023] Select corn and sorghum with full grains and no pests and diseases to form a grain seed mixture according to the mass ratio of 1:1. The mixture is cleaned, soaked in a sodium selenite solution with a concentration of 50mg / l at a temperature of 40-45°C for 18 hours, and then Drain, after about 3 mm of germination, wash the germinated grain seed mixture with salt water, air-dry, and superfinely pulverize to obtain selenium-enriched grain micropowder; mix selenium-enriched grain micropowder, konjac micropowder, and fruit and vegetable micropowder according to the mass ratio of 10: The mixture is prepared after a ratio of 6:1, and the prepared mixture is added to the sodium selenite solution with a concentration of 35mg / L according to the mass ratio of 0.25:1 to obtain a suspension, and then 2% by weight of the suspension is added to the yeast The mixed strains of bacteria and lactic acid bacteria are fermented in liquid state, the fermentation temperature is controlled at 3...

Embodiment 2

[0025] Select barley, wheat, and sesame with full grains and no pests and diseases to form a grain seed mixture according to the mass ratio of 1:1:1. The mixture is cleaned, and the concentration is 45mg / l. Soak for 20 hours, then drain, wash the germinated grain seed mixture with salt water after about 3 mm of germination, blast drying, and then superfinely pulverize to obtain selenium-enriched grain micropowder; mix selenium-enriched grain micropowder, konjac micropowder, and fruit and vegetable micropowder according to The mass ratio of 12:5:1 is used to prepare the mixture, and the prepared mixture is added to the sodium selenite solution with a concentration of 35mg / L according to the mass ratio of 0.4:1 to obtain a suspension, and then the weight of the suspension is Add 2.5% of the mixed strains of yeast and acetic acid bacteria to carry out liquid fermentation. The fermentation temperature is controlled at 30°C and the fermentation time is 60 hours. A mixture composed ...

Embodiment 3

[0027] Select buckwheat, soybean and rice with full grains and no pests and diseases to form a grain seed mixture according to the mass ratio of 1:1:3. The mixture is cleaned and soaked in a sodium selenite solution with a concentration of 60mg / l at a temperature of 30-38°C 12 hours, then drained, and after germinating 2 to 6 mm, wash the germinated grain seed mixture with salt water, air-dry, and then superfinely pulverize to obtain selenium-enriched grain powder; mix selenium-enriched grain powder, konjac powder, and fruit and vegetable powder The mixture is prepared after the mass ratio of 8:8:1, and the prepared mixture is added to the sodium selenite solution with a concentration of 35mg / L according to the mass ratio of 0.2:1 to obtain a suspension, and then the weight of the suspension is Add 4% acetic acid bacteria for liquid fermentation, the fermentation temperature is controlled at 28°C, and the fermentation time is 50 hours; the fermented suspension is centrifuged, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com