Nanometer carbon micro-crystal modified polylactic acid-based orthopedic material and method for preparing same

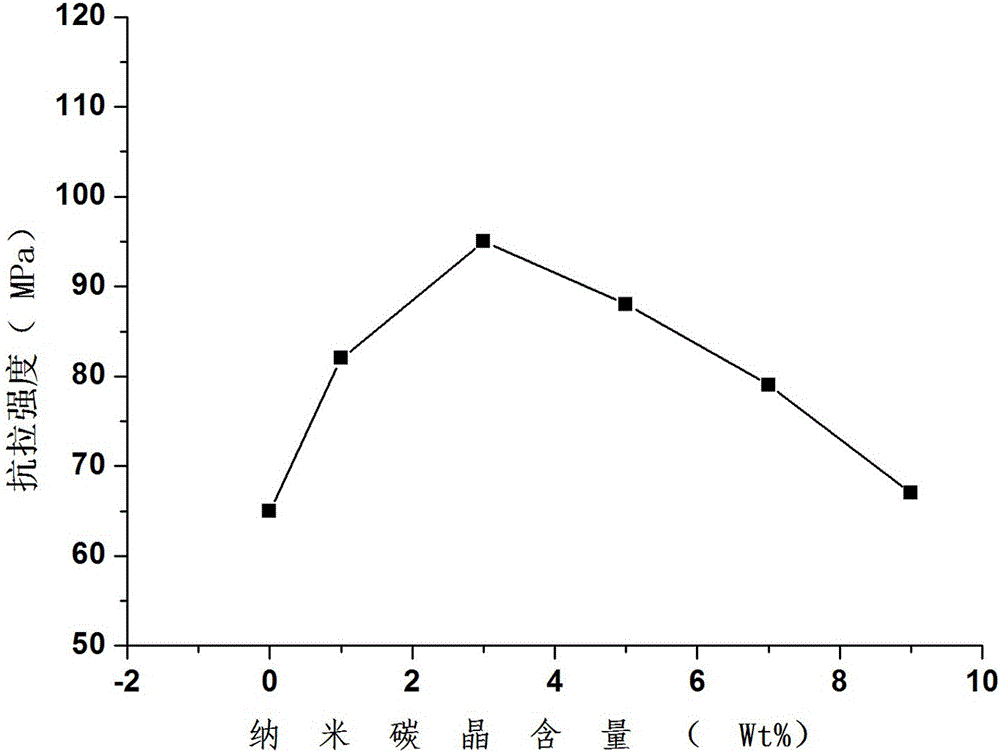

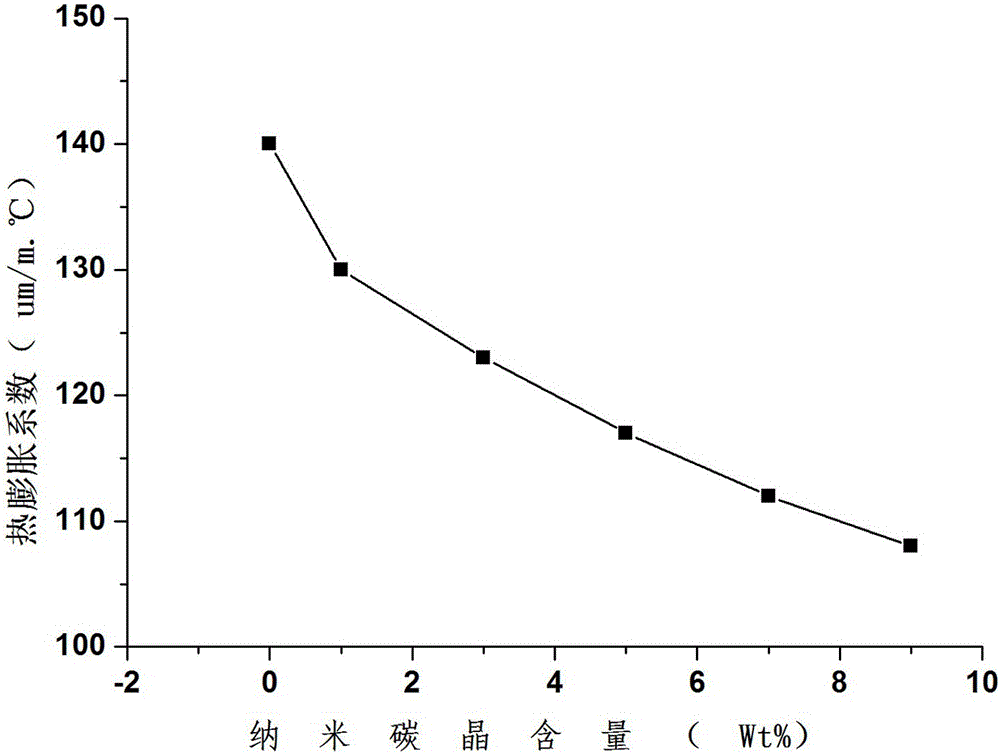

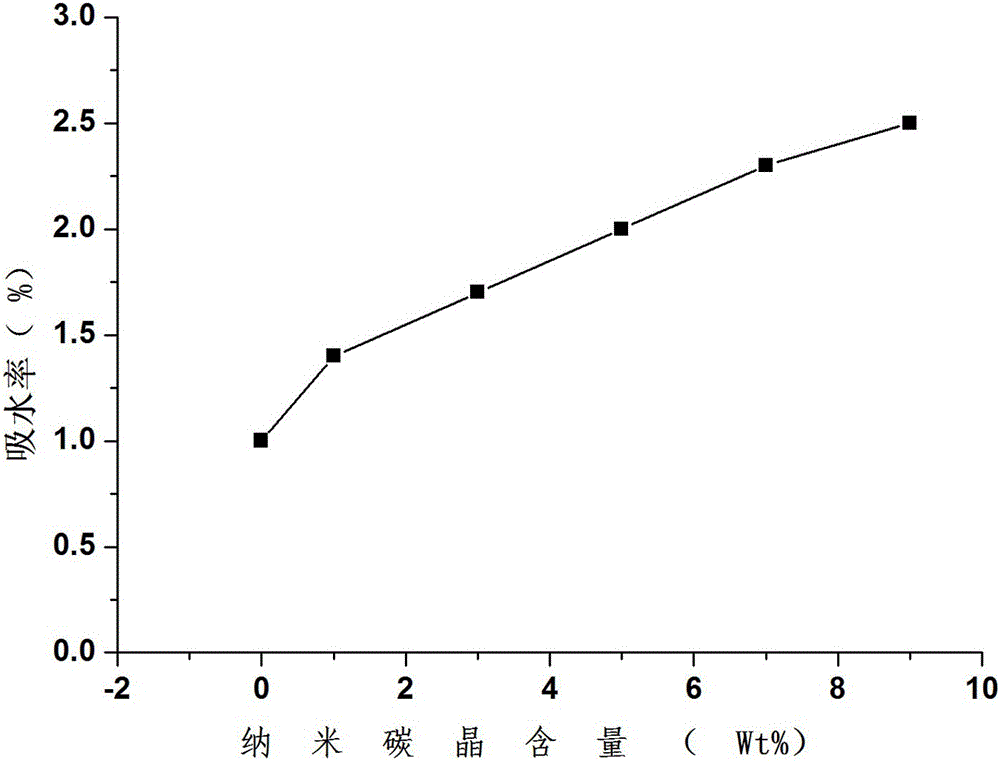

A nano-carbon crystal, polylactic acid-based technology, used in medical science, pharmaceutical formulations, prostheses, etc., can solve the problems of inability to uniformly disperse nano-materials, large thermal expansion coefficient, low strength, etc., and is conducive to bonding and reducing thermal expansion coefficient. , Improve the effect of tensile strength and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A polylactic acid-based orthopedic material modified by nano-carbon crystals is made of the following raw materials in weight percentage: 89 wt% of lactide, 1 wt% of catalyst, and 10 wt% of nano-carbon crystals.

[0031] The above-mentioned nano-carbon crystals are modified nano-carbon crystals, and the modification method is as follows:

[0032] a. Ultrasonic alkaline cleaning: put the nano-carbon crystal into an ultrasonic cleaning machine equipped with lye and stir and clean it. The ultrasonic frequency is 25KHz, and the alkaline cleaning is 10wt% NaOH solution. The temperature of the lye is 50°C, and the stirring speed is 25rpm. Stirring time is 25min;

[0033] b. Ultrasonic water washing: Put the nano-carbon crystals after alkali washing into an ultrasonic cleaner equipped with deionized water and stir and clean them. The ultrasonic frequency is 30KHz, the stirring speed is 25rpm, and the stirring time is 25min. Take the supernatant to measure the pH value , wash ...

Embodiment 2

[0041] A polylactic acid-based orthopedic material modified by nano-carbon crystals is characterized in that it is made of the following raw materials in weight percentages: lactide 94 wt%, catalyst 0.3 wt%, and nano-carbon crystals 5.7 wt%.

[0042] The above-mentioned nano-carbon crystals are modified nano-carbon crystals, and the modification method is as follows:

[0043] a. Ultrasonic alkaline cleaning: put the nano-carbon crystal into an ultrasonic cleaning machine equipped with lye and stir and clean it. The ultrasonic frequency is 30KHz, and the alkaline cleaning is 11wt% NaOH solution. The temperature of the lye is 55°C, and the stirring speed is 27rpm. Stirring time is 27min;

[0044] b. Ultrasonic water washing: Put the nano-carbon crystals after alkali washing into an ultrasonic cleaner equipped with deionized water and stir and clean them. The ultrasonic frequency is 30KHz, the stirring speed is 27rpm, and the stirring time is 27min. Take the supernatant to measur...

Embodiment 3

[0052] A polylactic acid-based orthopedic material modified by nano-carbon crystals is characterized in that it is made of the following raw materials in weight percentages: lactide 96 wt%, catalyst 2 wt%, and nano-carbon crystals 2 wt%.

[0053] The above-mentioned nano-carbon crystals are modified nano-carbon crystals, and the modification method is as follows:

[0054] a. Ultrasonic alkaline cleaning: put the nano-carbon crystal into an ultrasonic cleaning machine equipped with lye and stir and clean it. The ultrasonic frequency is 32KHz, and the alkaline cleaning is 11wt% NaOH solution. The temperature of the lye is 56°C, and the stirring speed is 26rpm. Stirring time is 26min;

[0055] b. Ultrasonic water washing: Put the nano-carbon crystals after alkali washing into an ultrasonic cleaner equipped with deionized water to stir and clean. The ultrasonic frequency is 30KHz, the stirring speed is 26rpm, and the stirring time is 26min. Take the supernatant to measure the pH v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com