Air purification material capable of releasing anions as well as preparation method and application of air purification material

An air purification material and technology of negative ions, applied in separation methods, chemical instruments and methods, air quality improvement and other directions, can solve the problems of high price, poor pollutant adsorption treatment effect, large difference in pore size of activated carbon, etc., and achieve low production cost. , the treatment effect is significant, the treatment time is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

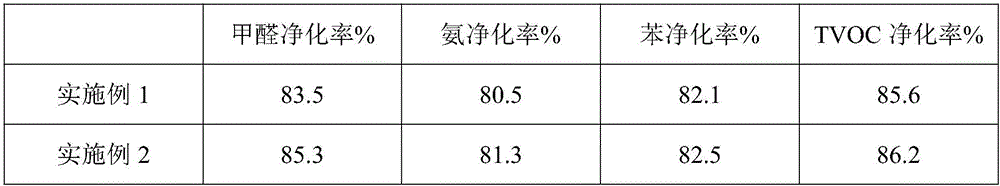

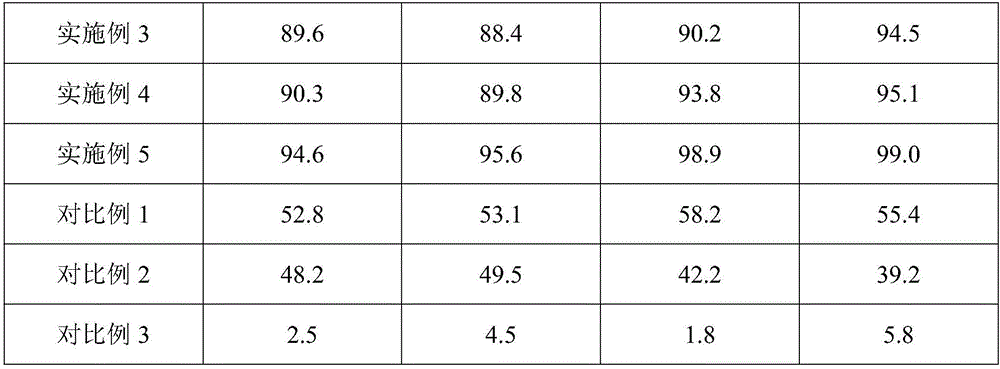

Examples

Embodiment 1

[0020] In the embodiment of the present invention, an air purification material that releases negative ions is composed of the following raw materials in parts by weight: 28 parts of red jade soil, 1 part of ethyl croton oleate, 11 parts of black essence, 5 parts of butanediol, tartaric acid Potassium 3 parts.

[0021] Potassium tartrate is mixed with 9.5 times the mass of deionized water to prepare potassium tartrate solution; ethyl crotonoleate is mixed with 2.5 times the mass of deionized water to prepare ethyl crotonoleate solution. Akadama was crushed and passed through a 100-mesh sieve, then mixed with ethyl crotonoleate solution and butanediol, and heated and stirred under a nitrogen atmosphere for 80 minutes under a nitrogen atmosphere at a heating temperature of 71°C to obtain mixture A. Pulverize the basalt, pass through a 100-mesh sieve, mix it with potassium tartrate solution, and stir it at 65°C for 65 minutes to prepare mixture B. Mix mixture A and mixture B, th...

Embodiment 2

[0023] In the embodiment of the present invention, an air purification material that releases negative ions is composed of the following raw materials in parts by weight: 36 parts of red jade soil, 5 parts of ethyl crotonoleate, 19 parts of black essence, 12 parts of butanediol, tartaric acid Potassium 7 parts.

[0024] Potassium tartrate is mixed with 9.5 times the mass of deionized water to prepare potassium tartrate solution; ethyl crotonoleate is mixed with 2.5 times the mass of deionized water to prepare ethyl crotonoleate solution. Akadama was crushed and passed through a 100-mesh sieve, then mixed with ethyl crotonoleate solution and butanediol, and heated and stirred under a nitrogen atmosphere for 80 minutes under a nitrogen atmosphere at a heating temperature of 71°C to obtain mixture A. Pulverize the basalt, pass through a 100-mesh sieve, mix it with potassium tartrate solution, and stir it at 65°C for 65 minutes to prepare mixture B. Mix mixture A and mixture B, t...

Embodiment 3

[0026] In the embodiment of the present invention, an air purification material that releases negative ions is composed of the following raw materials in parts by weight: 30 parts of red jade soil, 2 parts of ethyl crotonoleate, 13 parts of black essence, 7 parts of butanediol, tartaric acid Potassium 4 parts.

[0027] Potassium tartrate is mixed with 9.5 times the mass of deionized water to prepare potassium tartrate solution; ethyl crotonoleate is mixed with 2.5 times the mass of deionized water to prepare ethyl crotonoleate solution. Akadama was crushed and passed through a 100-mesh sieve, then mixed with ethyl crotonoleate solution and butanediol, and heated and stirred under a nitrogen atmosphere for 80 minutes under a nitrogen atmosphere at a heating temperature of 71°C to obtain mixture A. Pulverize the basalt, pass through a 100-mesh sieve, mix it with potassium tartrate solution, and stir it at 65°C for 65 minutes to prepare mixture B. Mix mixture A and mixture B, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com