Chinese-chestnut-epiear-based photocatalytic honeycomb activated carbon and waste-gas purifying equipment thereof

A technology based on photocatalytic honeycomb and honeycomb activated carbon, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, alkali metal oxide/hydroxide, etc. It can solve the problem of reducing the adsorption performance of the original powder activated carbon, troublesome regeneration, and difficult to restore adsorption. quantity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

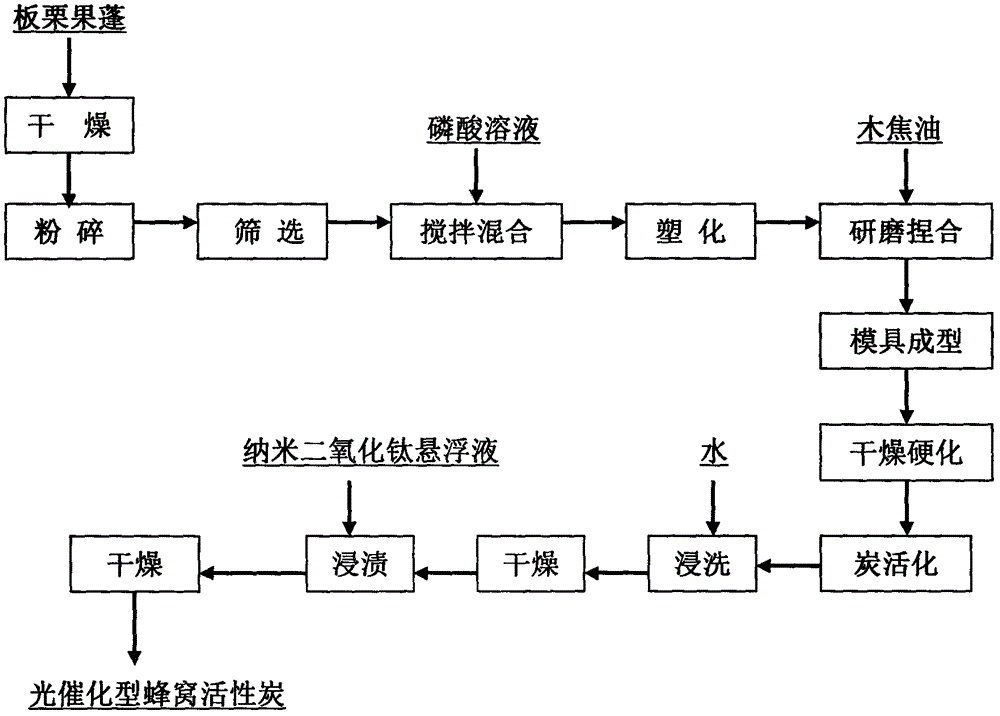

[0013] Dry the chestnut canopy until the water content is less than 20%, crush it into 20-60 mesh with a pulverizer, take 1000 grams of powdered material and phosphoric acid solution with a concentration of 60%, and put it in the mixing equipment according to the ratio of acid material weight ratio of 2.5:1 Stir and mix evenly, then put the mixture in plasticizing equipment and plasticize at 110°C for 4 hours, add wood tar to the plasticizing material and wood tar in a weight ratio of 5:1 and mix evenly, and grind in the grinding equipment Knead for 1 hour, then place it in a mold and press it into a honeycomb shape, dry and harden it at 200°C with a drying device, and finally place it in a carbon activation device and activate it at 550°C for 3 hours to make the honeycomb activated carbon Cool to below 200°C, soak in hot water to recover phosphoric acid, until the PH value of the charcoal is ≥ 5, dry at 200°C with drying equipment, place the honeycomb activated carbon in a con...

example 2

[0015]Dry the chestnut canopy until the water content is less than 20%, crush it into 20-60 mesh with a pulverizer, take 1000 grams of powdered material and 75% phosphoric acid solution and stir in the mixing equipment according to the ratio of acid material weight ratio of 2.0:1 Mix evenly, then put the mixture in plasticizing equipment and plasticize at 110°C for 3 hours, add wood tar to the plasticizing material and wood tar in a weight ratio of 5:1, mix evenly, and grind and knead in the grinding equipment for 1 hours, then put it in a mold and press it into a honeycomb shape, dry and harden it with a drying device at 200°C, and finally place it in a carbon activation device and activate it at 500°C for 3 hours, and cool the honeycomb activated carbon to Below 200°C, soak in hot water to recover phosphoric acid until the pH value is ≥ 5, dry at 200°C with drying equipment, and place honeycomb activated carbon in 2% nano-titanium dioxide suspension Immersed for 2 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com