a magnetic fe 3 o 4 @c/tio 2 -in 2 o 3 Composite photocatalyst and preparation method and application

A composite light and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as excessive band gap, achieve low cost, avoid The effect of secondary pollution and green environmental protection treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

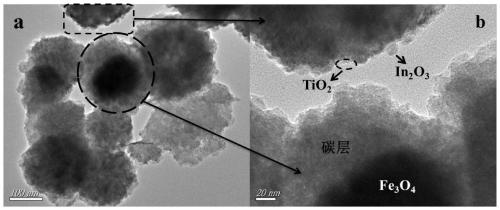

[0027] (1) Magnetic Fe 3 o 4 Preparation of @C nanospheres

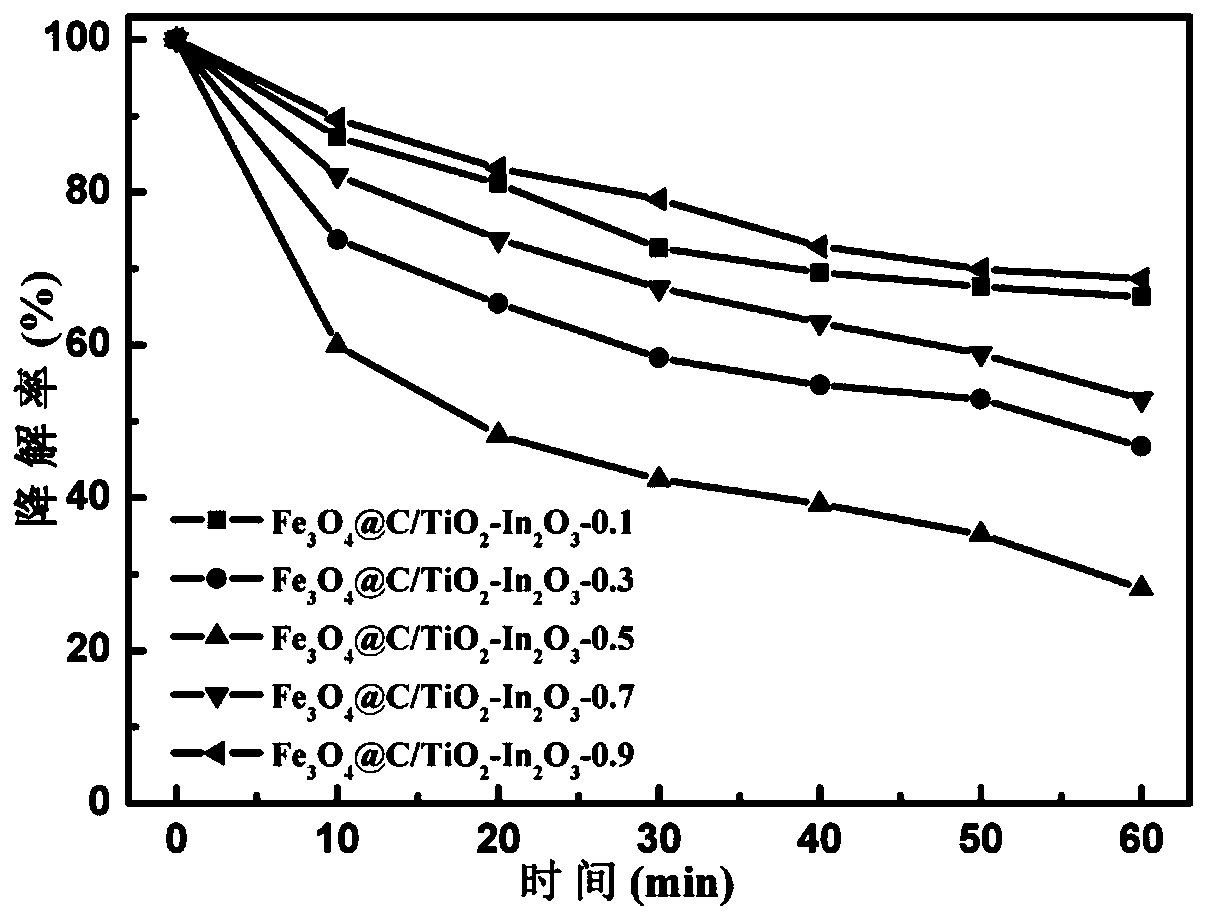

[0028] a. Weigh 0.1g of yeast, 2.4g of ferric chloride hexahydrate, 3.4g of sodium acrylate, and 3.4g of sodium acetate and dissolve them in a beaker of 22.5mL of ethylene glycol and 22.5mL of diethylene glycol. The mixed solution is sonicated for about 1 hour, and magnetically Stir, after dissolving, transfer the solution to a 100ml Teflon-lined reactor, react at 200°C for 10h, cool to room temperature, wash the product three times with deionized water and absolute ethanol, and put it at 65°C Oven dry. (2) Fe 3 o 4 @C / TiO 2 –In 2 o 3 Preparation of Composite Photocatalyst

[0029] Weigh 0.2g Fe 3 o 4@C was dissolved in a beaker of 40ml absolute ethanol, and the mixed solution was ultrasonically dispersed for about 30min. Secondly, In(NO 3 ) 3 , 0.2 mL tetrabutyl titanate and 0.1 mL deionized water were added to the above solution and stirred magnetically for 10 min. The resulting suspension was transfe...

Embodiment 2

[0031] b. Weigh 0.3g of yeast, 2.4g of ferric chloride hexahydrate, 3.4g of sodium acrylate, and 3.4g of sodium acetate and dissolve them in a beaker of 22.5mL of ethylene glycol and 22.5mL of diethylene glycol. The mixed solution is sonicated for about 1 hour, magnetically Stir, after dissolving, transfer the solution to a 100ml Teflon-lined reactor, react at 200°C for 10h, cool to room temperature, wash the product three times with deionized water and absolute ethanol, and put it at 65°C Oven dry. (2) Fe 3 o 4 @C / TiO 2 –In 2 o 3 Preparation of Composite Photocatalyst

[0032] Weigh 0.2g Fe 3 o 4 @C was dissolved in a beaker of 40ml absolute ethanol, and the mixed solution was ultrasonically dispersed for about 30min. Secondly, In(NO 3 ) 3 , 0.2 mL tetrabutyl titanate and 0.1 mL deionized water were added to the above solution and stirred magnetically for 10 min. The resulting suspension was transferred to a 100ml polytetrafluoroethylene-lined reaction kettle, kept...

Embodiment 3

[0034] c. Weigh 0.5g of yeast, 2.4g of ferric chloride hexahydrate, 3.4g of sodium acrylate, and 3.4g of sodium acetate and dissolve them in a beaker of 22.5mL of ethylene glycol and 22.5mL of diethylene glycol. The mixed solution is sonicated for about 1 hour, and magnetically Stir, after dissolving, transfer the solution to a 100ml Teflon-lined reactor, react at 200°C for 10h, cool to room temperature, wash the product three times with deionized water and absolute ethanol, and put it at 65°C Oven dry. (2) Fe 3 o 4 @C / TiO 2 –In 2 o 3 Preparation of Composite Photocatalyst

[0035] Weigh 0.2g Fe 3 o 4 @C was dissolved in a beaker of 40ml absolute ethanol, and the mixed solution was ultrasonically dispersed for about 30min. Secondly, In(NO 3 ) 3 , 0.2 mL tetrabutyl titanate and 0.1 mL deionized water were added to the above solution and stirred magnetically for 10 min. The resulting suspension was transferred to a 100ml polytetrafluoroethylene-lined reaction kettle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com