Treatment method for methoxyl acrylate pesticide product wastewater

A methoxyacrylic acid treatment method technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of high CODcr concentration in wastewater, no economic benefits, increased disposal costs, etc., to achieve treatment Good effect, save energy and water resources, solve high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

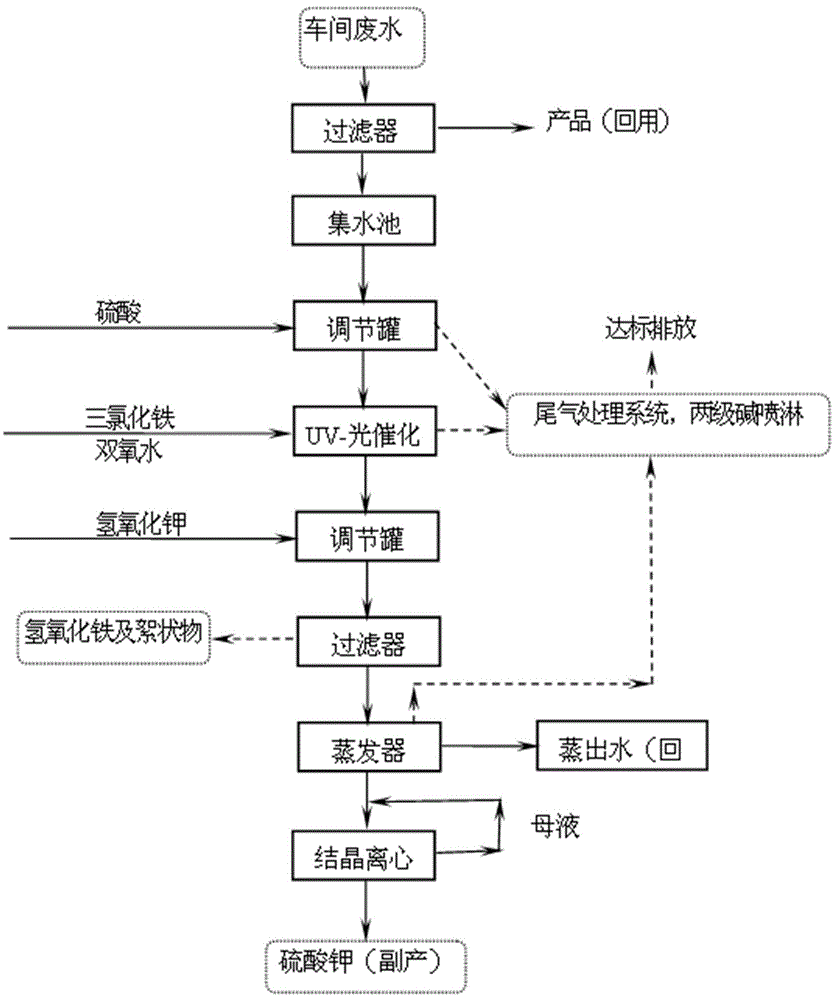

Method used

Image

Examples

Embodiment 1

[0040] The first step is waste water collection and filtration and recycling products: the workshop produces 38 tons of waste water every day. The waste water enters the waste water collection tank with a cone-shaped bottom. The waste water pump outlet is equipped with a double filter for filtering and recycling products. 0.5 tons of products can be recycled every day. The double filter is equipped with pressure interlocking control. When the pressure of one filter is high, it will alarm and switch to the other to avoid clogging and affect the continuity of the treatment process. 37.5 tons of filtrate are produced per day and enter the second step of treatment.

[0041] The second step is to adjust the pH: the wastewater is 3.0m 3 / h is pumped into the pH adjustment tank, and 98% sulfuric acid is added at the same time. The ratio of acid to waste water is controlled according to the mass flow meter. The sulfuric acid is added at 114kg / h, and the pH is automatically adjusted to 2.5,...

Embodiment 2

[0048] The first step is the same as in Example 1.

[0049] The second step is to adjust the pH: the wastewater is 3.2m 3 / h is pumped into the pH adjustment tank, and 80% waste sulfuric acid is added at the same time. The ratio of acid to waste water is controlled according to the mass flowmeter. The sulfuric acid is added at 150kg / h, and the pH is automatically adjusted to 2.8, so that potassium carbonate (46kg / h) It reacts with potassium bicarbonate salt (150kg / h) to produce potassium sulfate (190kg / h), and the tail gas is introduced into the alkaline washing spray tower through the induced air system for treatment.

[0050] The third step, UV-photocatalytic oxidation: pH = 2.8 wastewater with 3.3m 3 / h is pumped into the UV-photocatalytic oxidation process system to pre-treat the wastewater. The automatic dosing system is used to input 30% hydrogen peroxide and 35% ferric chloride solution, the dosage is 1450ppm, 200ppm, and passes through the hydroxyl radical The oxidation ef...

Embodiment 3

[0056] The first step is the same as in Example 1.

[0057] The second step is to adjust the pH: the wastewater is 3.2m 3 / h is pumped into the pH adjustment tank, and 98% sulfuric acid is added at the same time. The ratio of acid to waste water is controlled according to the mass flow meter. The sulfuric acid is added at 125kg / h, and the pH is automatically adjusted to 3.0, so that potassium carbonate (48kg / h ) And potassium bicarbonate salt (152kg / h) react to produce potassium sulfate (193kg / h), and the tail gas is introduced into the alkaline washing spray tower through the induced air system for treatment.

[0058] The third step, UV-photocatalytic oxidation: pH=3.0 wastewater with 3.3m 3 / h is pumped into the UV-photocatalytic oxidation process system to pre-treat the wastewater. The automatic dosing system is used to input 30% hydrogen peroxide and 50% ferric chloride solution, and the dosage is 1400ppm and 150ppm, respectively, through the hydroxyl radical The oxidation effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com