Preparation method of MAX-phase porous ceramic

A technology of porous ceramics and blocks, which is applied in the field of preparation of MAX-phase porous ceramics, can solve the problems of large preparation equipment, complicated preparation procedures, waste of energy, etc., and achieve the effects of low sintering temperature, high purity and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

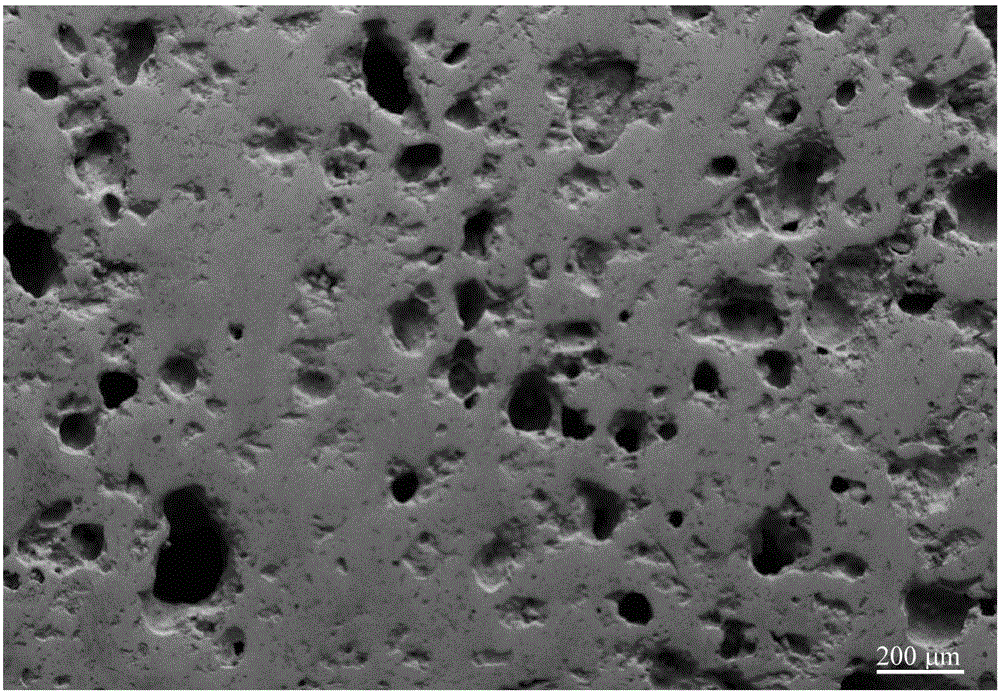

[0026] Take titanium powder, aluminum powder, and carbon powder with an average particle size of 200 mesh, and mix them according to 2:1:0.7. Wet ground in absolute ethanol with a mortar for 6 hours, thoroughly ground and dried. After putting a layer of carbon paper in the graphite mold, take an appropriate amount of mixture and add it to the graphite mold in batches. After adding a 3-5mm thick slurry, perform a pre-press. The pressure layers are preloaded sequentially. The mold used is a graphite mold with an inner diameter of 15-20mm. In order to ensure pressureless sintering, a punch with a slot is used so that the upper and lower punches are stuck on the sleeve, and the powder will not be damaged during the sintering process. Apply pressure, put the mold into the SPS sintering furnace, apply a pressure of 30MPa, carry out pressureless sintering at 1100°C, the heating rate is 100°C / min, fill with argon protection, take it out after holding for 10min, and obtain Ti 2 AlC b...

Embodiment 2

[0028] Take titanium powder, aluminum powder, and carbon powder with an average particle size of 250 mesh, and mix them according to 2:1.2:0.75. Wet ground in absolute ethanol with a mortar for 6.5 hours, thoroughly ground and dried. After putting a layer of carbon paper in the graphite mold, take an appropriate amount of mixture and add it to the graphite mold in batches. After adding a 3-5mm thick slurry, perform a pre-press. The pressure layers are preloaded sequentially. The mold used is a graphite mold with an inner diameter of 15-20mm. In order to ensure pressureless sintering, a punch with a slot is used so that the upper and lower punches are stuck on the sleeve, and the powder will not be damaged during the sintering process. Apply pressure, put the mold into the SPS sintering furnace, apply a pressure of 40MPa, carry out pressureless sintering at 1150°C, the heating rate is 100°C / min, fill with argon protection, take it out after holding for 10min, and obtain Ti 2 ...

Embodiment 3

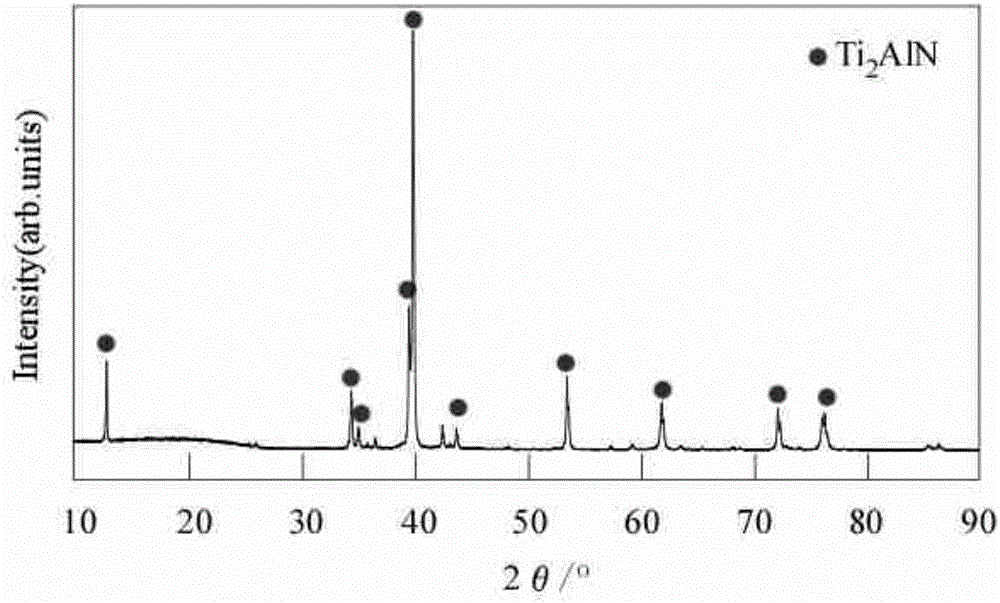

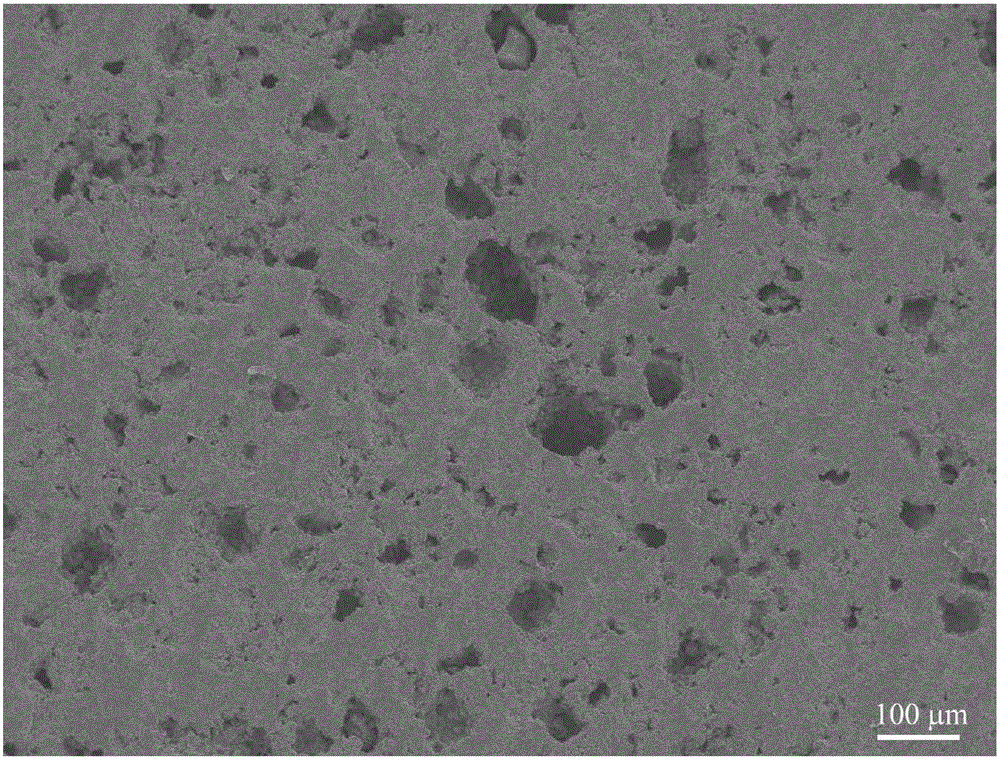

[0030]Take titanium powder, aluminum powder, and titanium nitride powder with a particle size of 300 mesh, and mix them according to 1:1.1:1. Wet ground in absolute ethanol with a mortar for 7 hours, thoroughly ground and dried. After putting a layer of carbon paper in the graphite mold, take an appropriate amount of mixture and add it to the graphite mold in batches. After adding a 3-5mm thick slurry, perform a pre-press. The pressure layers are preloaded sequentially. The mold used is a graphite mold with an inner diameter of 15-20mm. In order to ensure pressureless sintering, a punch with a slot is used so that the upper and lower punches are stuck on the sleeve, and the powder will not be damaged during the sintering process. put pressure on. Put the mold into the SPS sintering furnace, apply a pressure of 45MPa, and carry out pressureless sintering at 1300°C, with a heating rate of 100°C / min, filled with argon for protection, and take it out after holding for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com