Red phosphor that can be excited by near ultraviolet and blue light, preparation method and application

A technology of red phosphor and blue light excitation, which is applied in the field of preparation, red phosphor, and luminescent materials, can solve the problems of not meeting the application requirements of WLEDs, the high price of rare earth ions, and the lack of red phosphor, and meet the production conditions and equipment requirements. High, easy to handle, good crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

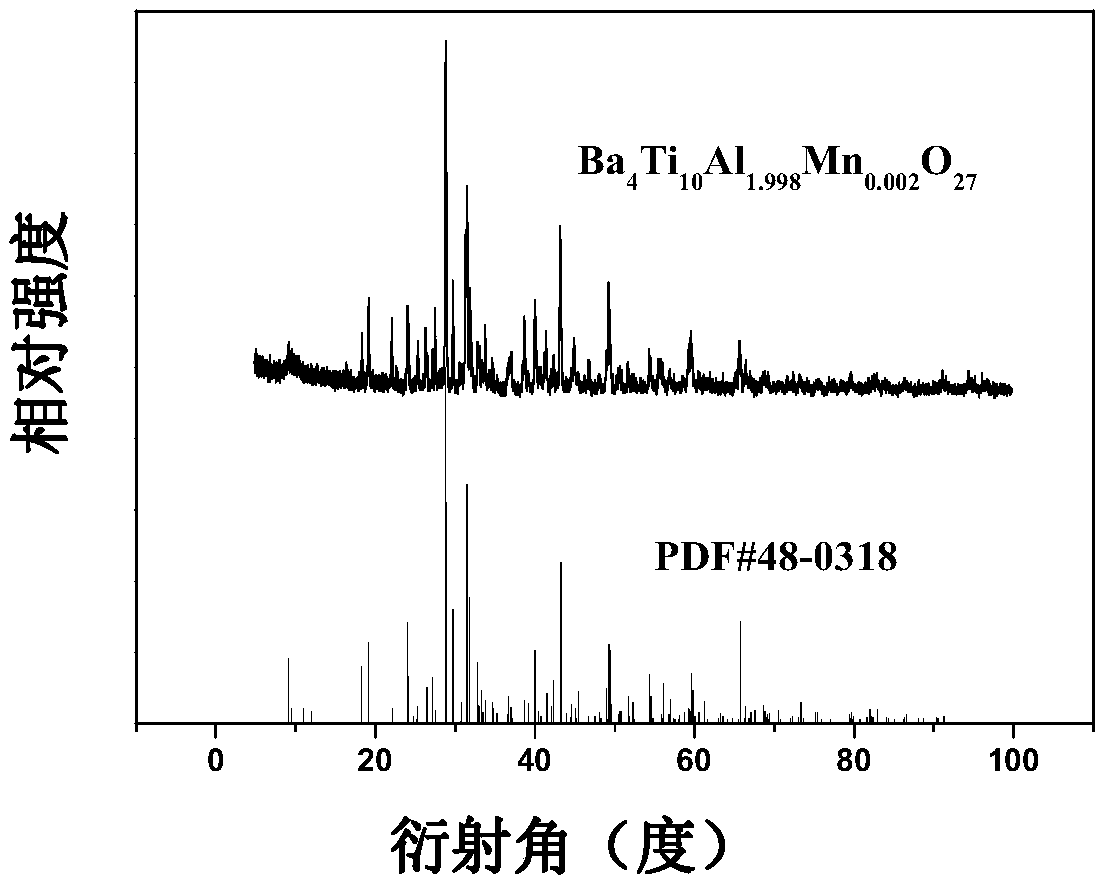

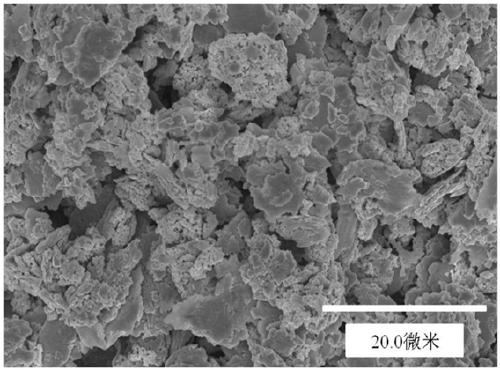

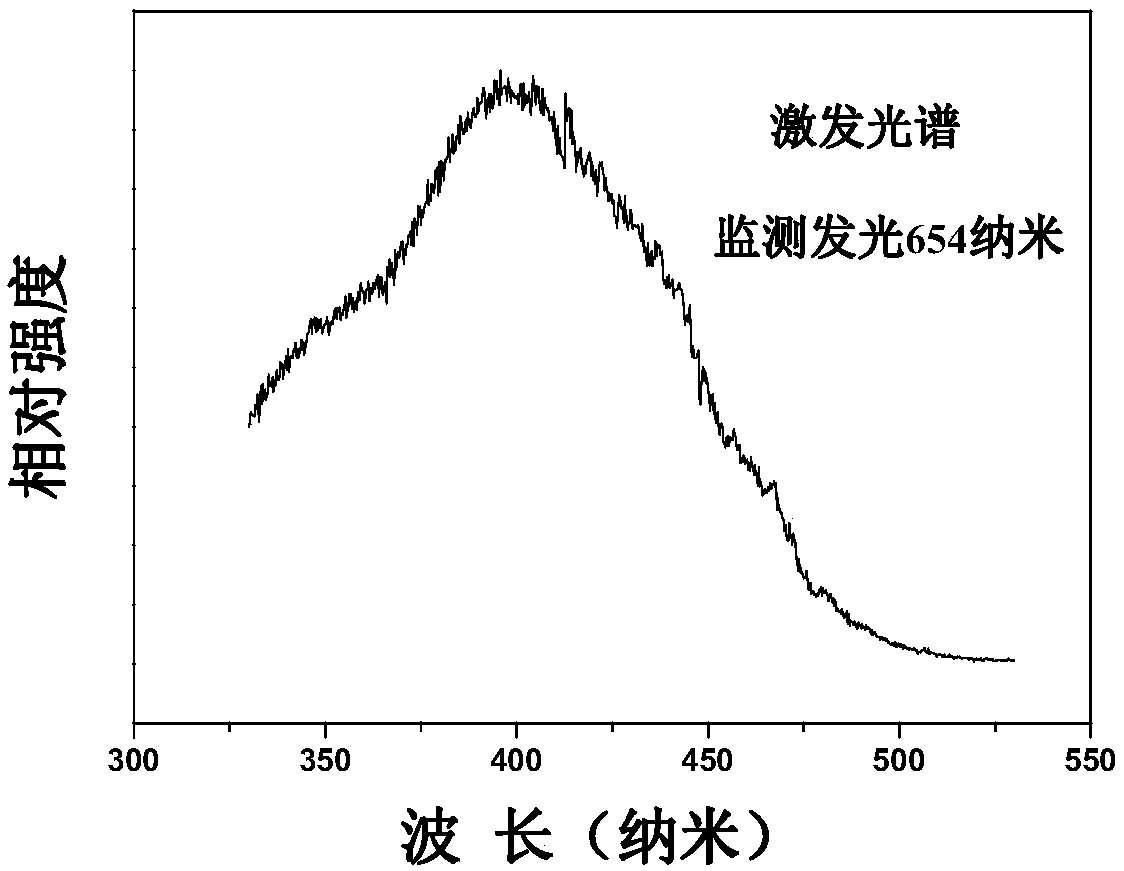

[0040] Preparation of Ba 4 Ti 10 al 1.998 mn 0.002 o 27

[0041] According to the chemical formula Ba 4 Ti 10 al 1.998 mn 0.002 o 27 , weigh barium nitrate Ba(NO 3 ) 2 : 6.9693 g, titanium dioxide TiO 2 : 5.3244 g, aluminum oxide Al 2 o 3 : 0.6791 g, manganese dioxide MnO 2 : 0.0012 g, fully ground in an agate mortar and mixed evenly, placed in an alumina crucible, pre-calcined for the first time in an air atmosphere, pre-calcined in a muffle furnace at 350 ° C for 5 hours, cooled to At room temperature, after taking out the sample, fully mix and grind evenly; then pre-calcine for the second time in an atmosphere containing oxygen, pre-calcine in a muffle furnace at 550°C for 7 hours, cool to room temperature, take out the sample and mix thoroughly and grind evenly again; Finally, in an atmosphere containing oxygen, calcined at 1050° C. for 9 hours in a muffle furnace, and cooled to room temperature to obtain a red phosphor activated by tetravalent manganese ion...

Embodiment 2

[0048] Preparation of Ba 4 Ti 10 al 1.99 mn 0.01 o 27

[0049] According to the chemical formula Ba 4 Ti 10 al 1.99 mn 0.01 o 27 , weigh barium carbonate BaCO 3 : 5.2624 g, titanium dioxide TiO 2 : 5.3244 grams, aluminum nitrate Al (NO 3 ) 3 9H 2 O: 2.8257 grams, manganese acetate Mn (CH 3 COO) 2 : 0.0115 g, fully ground in an agate mortar and mixed evenly, placed in an alumina crucible, pre-calcined for the first time in an air atmosphere, calcined in a muffle furnace at 400 ° C for 6 hours, cooled to room temperature , after taking out the sample, fully mix and grind evenly; then pre-calcine for the second time in an atmosphere containing oxygen, calcinate in a muffle furnace at 600 ° C for 8 hours, cool to room temperature, take out the sample and mix well again and grind evenly; finally In an atmosphere containing oxygen, calcining at 1100°C for 10 hours in a muffle furnace and cooling to room temperature can obtain a red phosphor activated by tetravalent m...

Embodiment 3

[0052] Preparation of Ba 4 Ti 10 al 1.986 mn 0.014 o 27

[0053] According to the chemical formula Ba 4 Ti 10 al 1.986 mn 0.014 o 27 , Weigh barium hydroxide Ba(OH) 2 : 4.5693 g, titanium dioxide TiO 2 : 5.3244 g, aluminum carbonate Al 2 (CO 3 ) 3 : 1.5491 g, manganese carbonate MnCO 3 : 0.0107 g, fully ground in an agate mortar and mixed evenly, placed in an alumina crucible, pre-calcined for the first time under air atmosphere, calcined in a muffle furnace at 300 ° C for 3 hours, cooled to room temperature , after taking out the sample, fully mix and grind evenly; then pre-calcine for the second time in an atmosphere containing oxygen, calcinate in a muffle furnace at 500 ° C for 6 hours, cool to room temperature, take out the sample and mix well again and grind evenly; finally in Calcined in a muffle furnace at 1000°C for 8 hours in an atmosphere containing oxygen, and cooled to room temperature to obtain a red phosphor activated by tetravalent manganese ions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com