Preparation method of modified thermoplastic polyurethane elastomer foam material

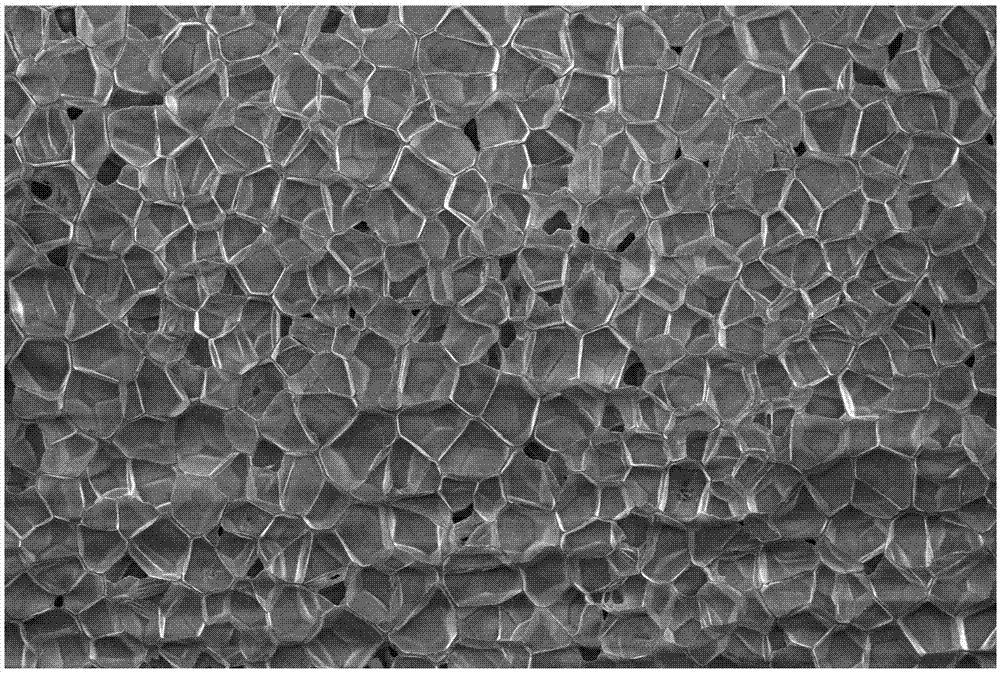

A thermoplastic polyurethane and foaming material technology, which is applied in the field of thermoplastic polyurethane elastomers and foaming materials, can solve the problems of uneven foaming, difficulty in control, and poor foaming effect, and achieve uniform cells, stable structure, and foaming The effect of controllable hole size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a modified thermoplastic polyurethane elastomer foaming material disclosed by the invention comprises the steps of:

[0027] (1) 100 parts by weight of thermoplastic polyurethane elastic material, 0.5-10 parts of modified graphene material and 0.05-3 parts of lubricant are stirred and mixed to obtain a compound; the obtained compound is melted and mixed, and after cooling, Pelletizing by a pelletizer to obtain thermoplastic polyurethane pellets uniformly doped with graphene;

[0028] (2) Add the pellets and water obtained in step (1) to a mass ratio of 1:0.3-1:2, and add them to the reactor to start stirring;

[0029] (3) feed carbon dioxide or nitrogen into the reactor, control pressure and temperature in the reactor, make carbon dioxide or nitrogen in the reactor supercritical;

[0030] (4) Reactor is heated, and reactor is under temperature, and supercritical carbon dioxide or and nitrogen are dissolved in the thermoplastic polyurethane grain ...

Embodiment 1

[0035] First, 100 parts of thermoplastic polyurethane elastic materials, 3 parts of modified graphene and 0.5 parts of lubricant are put into a high-speed mixer and mixed for 10 minutes; 150rmp, kneading at 135°C for 20min; then extruded by twin-screws and cooled in a water tank, then introduced into a pelletizer for pelletizing operation to obtain thermoplastic polyurethane pellets uniformly doped with graphene;

[0036] Then, the obtained thermoplastic polyurethane pellets and water are added into the reactor at a mass ratio of 1:1 to start stirring; carbon dioxide and nitrogen are introduced into the reactor, and the pressure in the reactor is controlled to be 7.5MPa and the temperature is 45°C, so that the inside of the reactor is Carbon dioxide and nitrogen are in a supercritical state; the reactor is heated to dissolve supercritical carbon dioxide or nitrogen in the thermoplastic polyurethane pellets uniformly doped with graphene at a temperature of 100°C in the reactor; ...

Embodiment 2

[0040] First, 100 parts of thermoplastic polyurethane elastic material, 5 parts of modified graphene oxide and 0.5 part of lubricant are put into a high-speed mixer and mixed for 20 minutes; 150rmp, mixed at 135°C for 20min; then extruded by twin-screw, cooled in a water tank, introduced into a pelletizer for pelletizing operation, to obtain thermoplastic polyurethane pellets uniformly doped with graphene;

[0041]Then, the obtained thermoplastic polyurethane pellets and water are added into the reactor at a mass ratio of 1:0.8 to start stirring; carbon dioxide and nitrogen are introduced into the reactor, and the pressure in the reactor is controlled to be 7.5MPa and the temperature is 50°C, so that the inside of the reactor is Carbon dioxide and nitrogen are in a supercritical state; the reactor is heated to dissolve supercritical carbon dioxide or nitrogen in the graphene-doped thermoplastic polyurethane pellets at a temperature of 110°C in the reactor;

[0042] Then live i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com