Fluorescent carbon quantum dot/mesoporous alumina composite luminescent material, and preparation method and application thereof to oxygen sensing aspect

A technology of mesoporous alumina and carbon quantum dots, which can be used in luminescent materials, fluorescence/phosphorescence, alumina/aluminum hydroxide, etc. High, luminous stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Preparation of fluorescent carbon quantum dot / mesoporous alumina composite luminescent material.

[0049] (1) Preparation of matrix material mesoporous alumina: 1.0g P123 as a template, then add 0.3g of anhydrous citric acid, 15mL of absolute ethanol as a solvent, stir to obtain a transparent solution, hydrochloric acid and glacial acetic acid to adjust the pH value to 2~ 3. Add 10mmol aluminum isopropoxide as the aluminum source, stir well at room temperature for 10h to obtain a white milk, transfer it to 40°C water into a pot, stir evenly for 4h, and put it in an 80°C oven for 48h. After high-temperature calcination, it is ground to obtain a white powder, which is the matrix material. The method is a sol-gel method to prepare the matrix material.

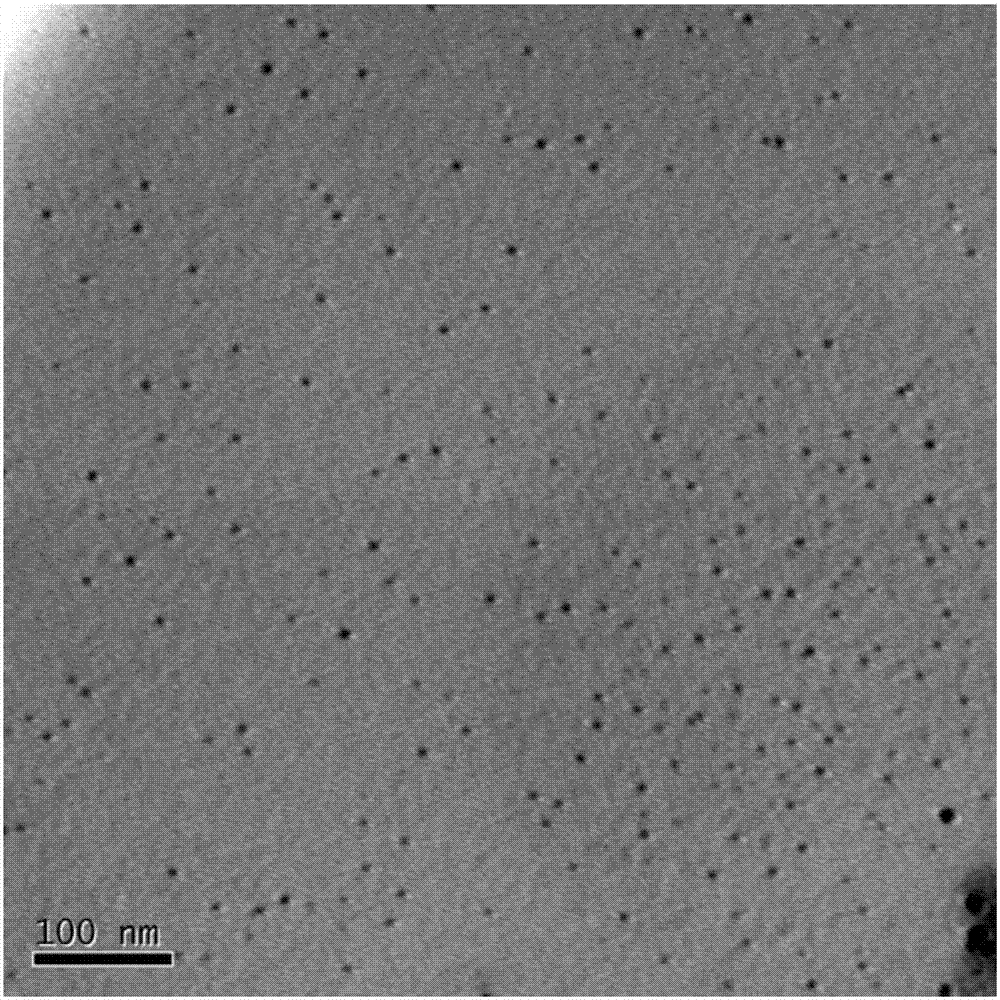

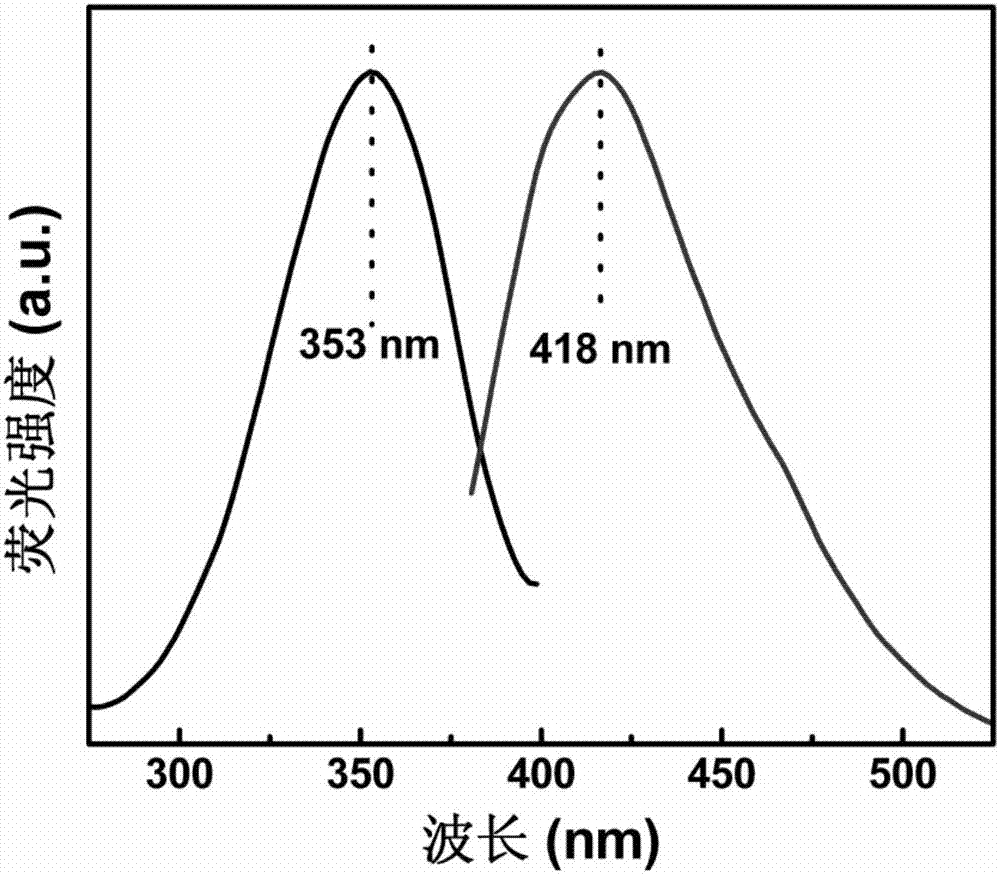

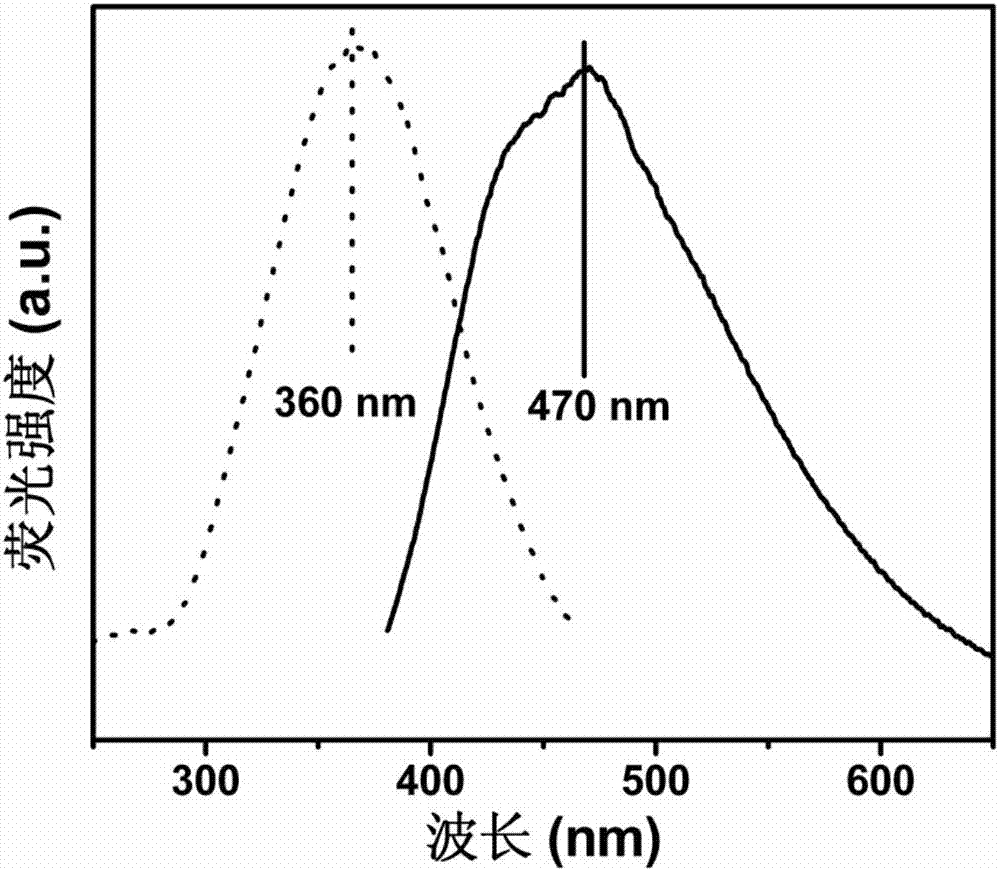

[0050] (2) Preparation method of fluorescent carbon quantum dots: 1.0g of polyvinyl alcohol, 0.75mL of ethylenediamine and 50mL of deionized water can be added in the same proportion. Set 10h. A brownish-yellow ...

Embodiment 2

[0052] Example 2: Preparation of fluorescent carbon quantum dots / mesoporous alumina composite luminescent material

[0053] (1) The preparation of matrix material mesoporous alumina refers to Example 1;

[0054] (2) Preparation method of fluorescent carbon quantum dots: dry fresh dried banana peel in an oven at 60°C for 10 hours, take 1.0 dried banana peel, 2mL 30%H 2 o 2 and 30mL deionized water, the same ratio can also be increased, the hydrothermal reaction is carried out at 160°C, and the time is set for 6h to obtain a brownish-yellow turbid liquid. yellow liquid. Freeze-dry to obtain solid carbon dots. Take 1.0 g of solid carbon dots and add 100 mL of deionized water to obtain a carbon dot solution with a concentration of 0.01 g / mL. The surface contains a large number of hydroxyl groups and the particle size is 6-8 nm.

[0055] (3) Take 1.0g of matrix material, add 1.0mL 0.01g / mL luminescent carbon quantum dots, stir rapidly for 5h, filter, dry in an oven at 60°C, and ...

Embodiment 3

[0056] Example 3: Preparation of fluorescent carbon quantum dots / mesoporous alumina composite luminescent material

[0057] (1) The preparation of matrix material mesoporous alumina refers to Example 1;

[0058] (2) Preparation method of fluorescent carbon quantum dots: 1.0g of anhydrous citric acid, 1.0mL of ethylenediamine and 50mL of deionized water are subjected to hydrothermal reaction, the temperature is set at 140°C, and the time is set for 8h. After the hydrothermal reaction, cool to room temperature to obtain Brown-yellow liquid, the purification steps are as follows: filter, centrifuge for 15 minutes at a speed of 15000 rpm / min, and dialyze (1000D) to obtain a brown-yellow liquid. Freeze-dry to obtain solid carbon dots. Take 1.0 g of solid carbon dots and mix with 100 mL of deionized water to obtain a carbon dot solution with a concentration of 0.01 g / mL. The surface contains a large number of hydroxyl groups and amino groups, and the particle size is 6-8 nm.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com