Carbon dots, preparation method therefor, carbon-dot composite material, preparation method therefor and luminescent LED (Light Emitting Diode)

A composite material and carbon nanodot technology, applied in the field of nanomaterials, can solve the problems of limiting the application of carbon nanodots, fluorescence quenching, low quantum efficiency of composite materials, etc., and achieve the effect of inhibiting aggregation-induced fluorescence quenching and high quantum efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing carbon nanodots, comprising:

[0037] After mixing citric acid and urea in a solvent, heating to obtain a reaction solution;

[0038] centrifuging the reaction solution to obtain carbon-nano dots;

[0039] The solvent is one or both of water, glycerol and dimethylformamide.

[0040] The invention uses citric acid and urea as raw materials to synthesize water-soluble carbon nano-dots through a solvothermal method. In the present invention, the mass ratio of citric acid and urea is preferably 1:(1-3), more preferably 1:(1.5-2.5), and most preferably 1:2. In the present invention, the mass ratio of the citric acid and urea to the solvent is preferably (2-4) g: (5-7) g: (20-40) mL, more preferably (2.5-3.5) g :(5.5~6.5)g:(25~35)mL, most preferably 3g:6g:30mL.

[0041] In the present invention, the heating can be carried out in a reactor, preferably in a steel-lined polytetrafluoroethylene reactor, and the heating is preferab...

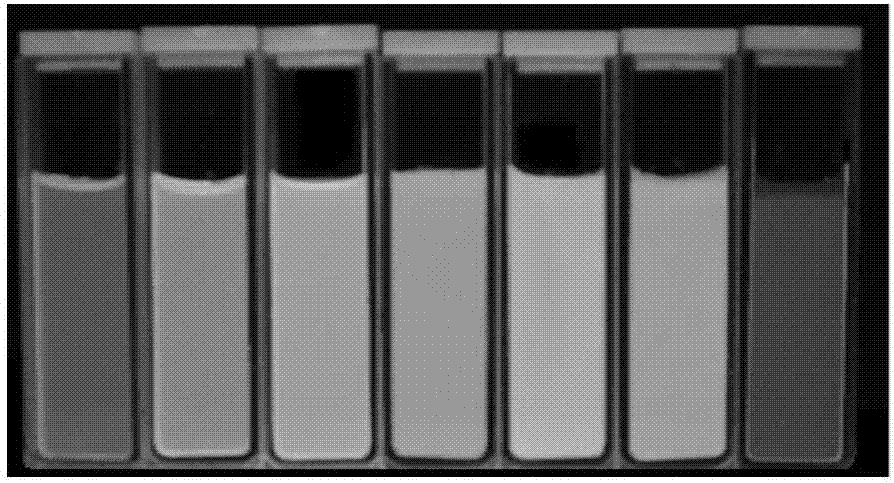

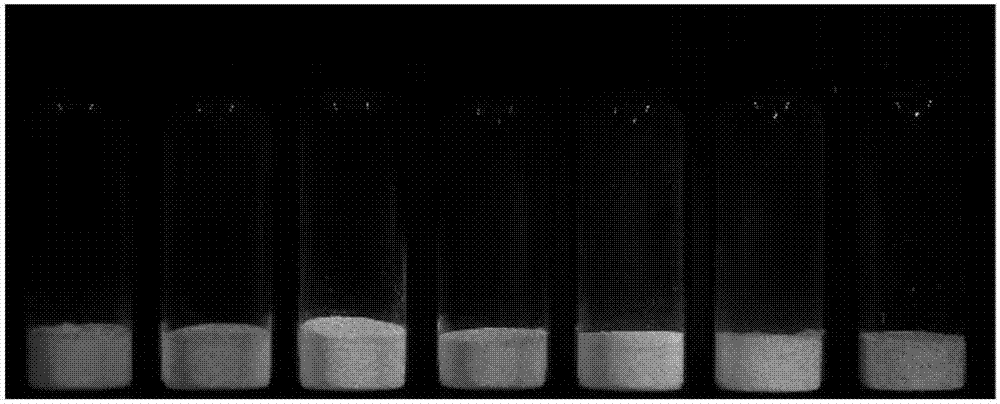

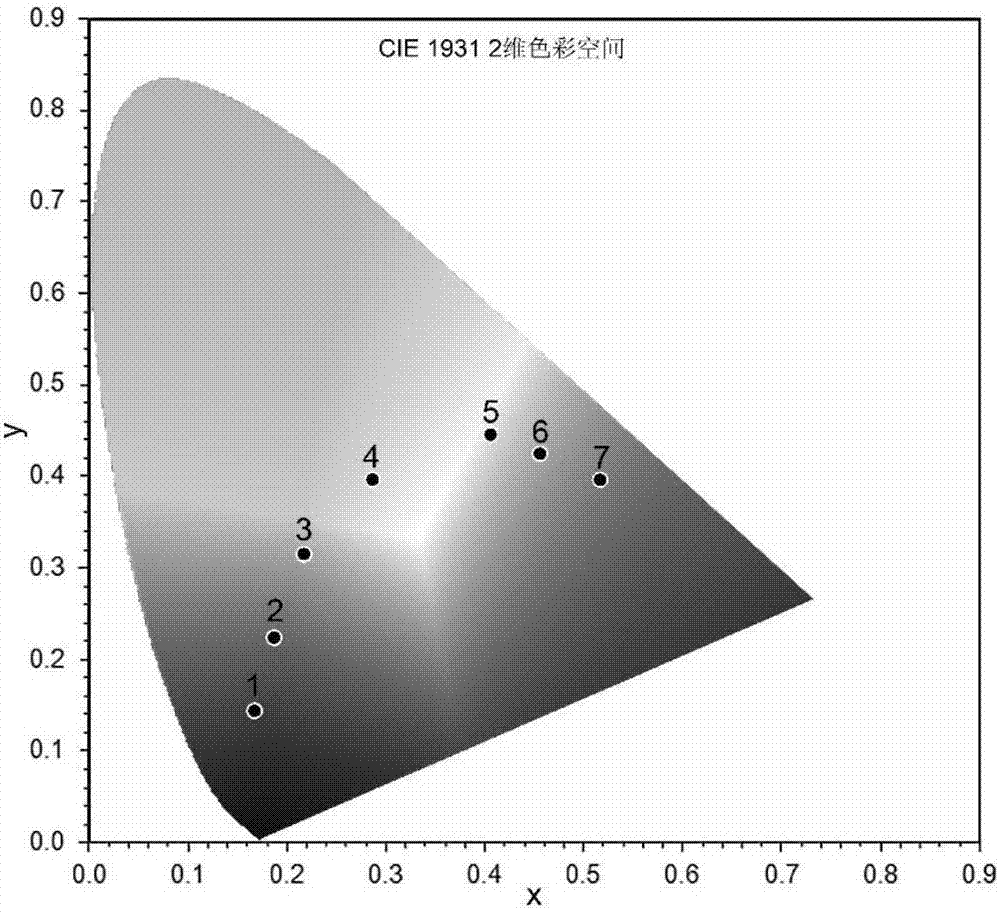

Embodiment 1

[0063] Mix and dissolve 3g of citric acid and 6g of urea in 30mL of deionized water to obtain a colorless and transparent solution;

[0064] The obtained colorless and transparent solution was added to a 50mL steel-lined polytetrafluoroethylene reactor, and sealed and heated at 160°C for 4 hours to obtain a reaction mixture;

[0065] The obtained reaction mixture was dissolved in 60 mL of ethanol, and centrifuged at a speed of 8000 rpm; the upper liquid was removed, the precipitate was dissolved in 60 mL of ethanol and centrifuged for about 3 times, and the precipitate was freeze-dried to obtain blue light carbon nanodots.

[0066] The obtained blue-light carbon nano-dots were detected by Hitachi F-7000 fluorescence spectrophotometer equipment, the optimal emission wavelength of the blue-light carbon nano-dots was 450nm, and the fluorescence quantum efficiency was 0.32.

[0067] Mix the blue-light carbon nano-dot aqueous solution with sodium water glass (liquid sodium silicate...

Embodiment 2

[0071] Carbon nanodots were prepared according to the method of Example 1. The difference from Example 1 was that the 30mL deionized in Example 1 was replaced with 30mL of water and glycerol with a volume ratio of 1:1 to obtain blue blue light carbon nanodots .

[0072] According to the method of Example 1, the blue cyan-light carbon nano-dots were prepared into carbon nano-dot composite phosphors.

[0073] According to the method of Example 1, the optimal emission wavelength of the blue-cyan light carbon nano-dots is 470nm, and the fluorescence quantum efficiency is 0.22. The emission wavelength of the carbon-nano-dot composite phosphor prepared in Example 2 is 460nm under ultraviolet excitation. The fluorescence quantum efficiency is 0.35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

| Emission wavelength | aaaaa | aaaaa |

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com