Advanced waterproof adhesive

A binder and advanced technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of harmful substances, poor weather resistance, poor adhesion, etc., and achieve low cost , Convenience in construction, effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

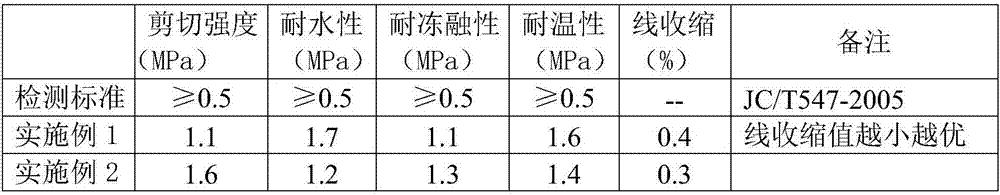

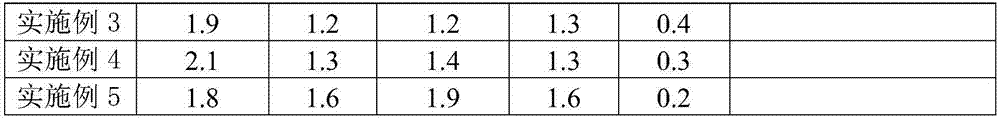

Examples

Embodiment 1

[0025] Select 60 parts by weight of styrene-acrylic emulsion, 20 parts by weight of heavy calcium carbonate (≤45 microns in the particle size range), 5 parts by weight of superfine talcum powder (≤45 microns in the particle size range), and 0.1 parts by weight of dioctyl phthalate , 0.5 parts by weight of hydroxyethyl cellulose ether, 0.2 parts by weight of organic bentonite, 0.5 parts by weight of fatty alcohol defoamer, 0.8 parts by weight of fatty alcohol polyoxyethylene ether, 0.3 parts by weight of sodium bicarbonate, 0.5 parts by weight of sodium pentachlorophenolate, Mix the above components according to the proportion, add 2 parts of deionized water, put it into a high-speed dispersion kettle and stir well to make a waterproof adhesive.

Embodiment 2

[0027] Select 80 parts by weight of silicon-acrylic emulsion, 10 parts by weight of light calcium carbonate (≤45 microns in the particle size range), 5 parts by weight of superfine talcum powder (≤45 microns in the particle size range), and 0.2 parts by weight of dioctyl phthalate , 0.4 parts by weight of hydroxyethyl cellulose ether, 0.4 parts by weight of organic bentonite, 0.3 parts by weight of fatty alcohol defoamer, 0.5 parts by weight of fatty alcohol polyoxyethylene ether, 0.3 parts by weight of sodium acetate, 0.3 parts by weight of sodium pentachlorophenolate, and Mix the above components according to the proportion, add 2 parts of deionized water, put it into a high-speed dispersion kettle and stir well to make a waterproof adhesive.

Embodiment 3

[0029] Select 80 parts by weight of acrylic acid emulsion, 10 parts by weight of light calcium carbonate, 5 parts by weight of lithopone (particle size range≤45 microns), 0.3 parts by weight of dioctyl phthalate, 0.3 parts by weight of sodium polyacrylate, organic bentonite 0.5 parts by weight, 0.3 parts by weight of fatty alcohol defoamer, 0.5 parts by weight of methacrylate, 0.3 parts by weight of aromatic amine antioxidants, 0.5 parts by weight of sodium 2,4,5-trichlorophenolate, the above components according to Proportionally mixed, add 3 parts of deionized water, put it into a high-speed dispersion kettle and stir well to make a waterproof adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com