Multifunctional coating for boron nitride fibers and preparation process of multifunctional coating

A multi-functional coating and boron nitride fiber technology, which is applied in fiber treatment, fiber type, textile and papermaking, etc., can solve the problem of BN fiber moisture resistance, poor oxidation resistance, restricting the development of BN fiber composite materials, and affecting the comprehensive performance of fibers problems such as improving moisture resistance and oxidation resistance, facilitating large-scale production, and repairing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

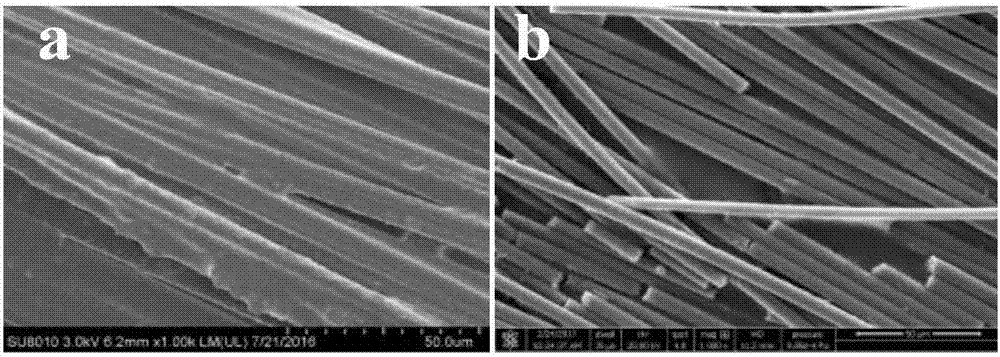

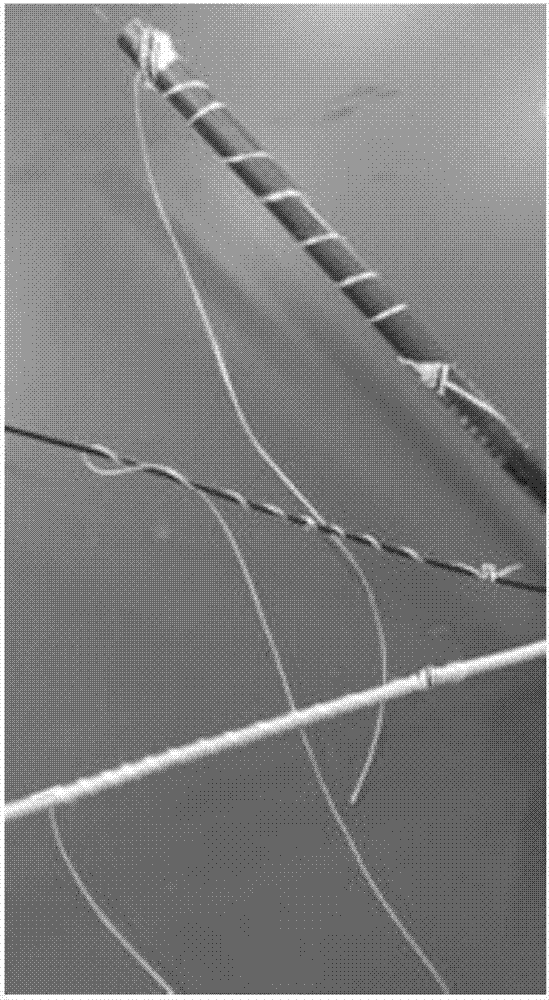

Image

Examples

Embodiment 1

[0043] (1) Accurately weigh 15.000g tetraethyl orthosilicate, 2.000g hydrochloric acid (mass fraction 30%), and 8.000g ethanol into a plastic beaker with an analytical balance;

[0044] (2) Quickly transfer the mixture of these three solutions to a clean wide-mouth reagent bottle and magnetically stir for 12 hours; advantages: firstly, the raw materials are mixed together evenly, and the transfer and stirring prevent the solution from volatilizing on the one hand, and on the other hand make the three substances Fully participate in the response.

[0045] (3) Add 20.000 g of ethanol to (2) and stir for 1 min;

[0046] (4) Filter the mixed solution in (3) into a pre-marked reagent bottle using chrysanthemum fast filter paper to obtain the stock solution of the BN fiber multifunctional coating, and the mass percentage concentration is 9.6%;

[0047] (5) According to a certain ratio, the stock solution in (4) is diluted with 40.000 g of ethanol to a coating with a concentration o...

Embodiment 2

[0053] (1) Accurately weigh 30.000g tetraethyl orthosilicate, 8.000g nitric acid (30% by mass fraction), and 20.000g ethanol into a plastic beaker with an analytical balance;

[0054] (2) The mixture of these three solutions is quickly transferred to a clean wide-mouth reagent bottle and magnetically stirred for 60 hours;

[0055] (3) Add 60.000g butyl acetate to (2) and stir for 30min;

[0056] (4) Filter the mixed solution in (3) into a pre-marked reagent bottle using chrysanthemum fast filter paper to obtain the stock solution of the BN fiber multifunctional coating, and the mass percentage concentration is 7.33%;

[0057] (5) According to a certain ratio, the stock solution in (4) is diluted with 120.000 g of ethanol to a coating with a concentration of 3.63% by mass;

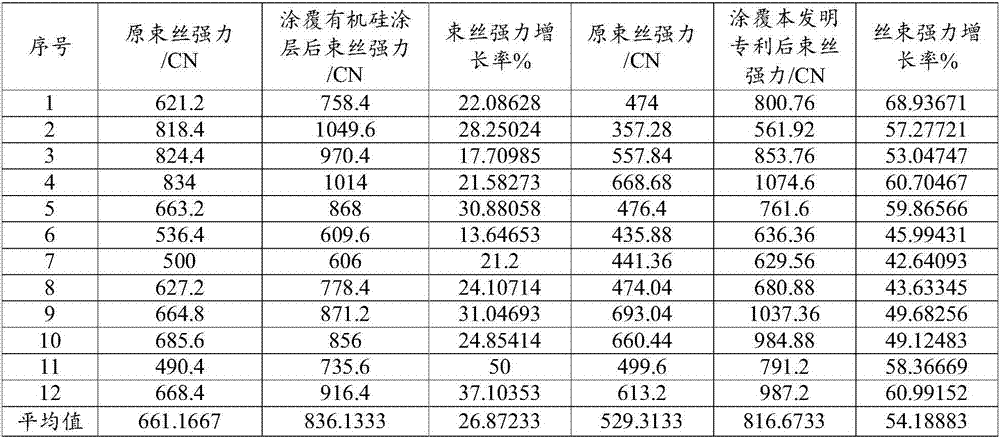

[0058] The boron nitride fiber strength of embodiment 2 coating treatment is 1368MPa, and the average value of fiber strength is 1359MPa after the BN fiber that has been processed is placed in the air for 12...

Embodiment 3

[0060] (1) Accurately weigh 20.000g tetraethyl orthosilicate, 6.000g sulfuric acid (30% by mass fraction), and 18.000g n-dodecane into a plastic beaker with an analytical balance;

[0061] (2) The mixture of these three solutions is quickly transferred to a clean wide-mouth reagent bottle and magnetically stirred for 24 hours;

[0062] (3) Add 50.000g butyl acetate to (2) and stir for 10min;

[0063] (4) Filter the mixed solution in (3) into a pre-marked reagent bottle using chrysanthemum fast filter paper to obtain the stock solution of the BN fiber multifunctional coating, and the mass percentage concentration is 6.14%;

[0064] (5) According to a certain ratio, the stock solution in (4) is diluted with 140.000 g of ethanol to a coating with a concentration of 2.46% by mass;

[0065] The boron nitride fiber strength of embodiment 3 coating treatment is 1380MPa, and the average value of fiber strength is 1369MPa after the processed BN fiber is placed in the air for 12 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com