A kind of preparation method of bipolar zinc-ion battery

A zinc-ion battery, bipolar technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem of very high battery consistency, achieve the effect of reducing free electrolyte, improving adhesion ability, and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Mix and stir graphite, epoxy resin, curing crosslinking agent and solvent according to the ratio of 2%, 4%, 0.8%, 93.2% (wt%) to form a conductive paste;

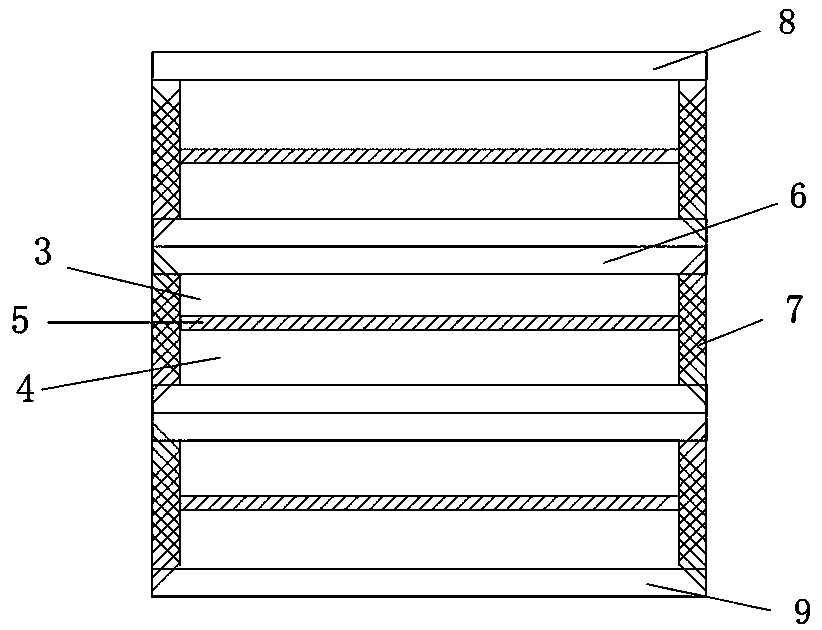

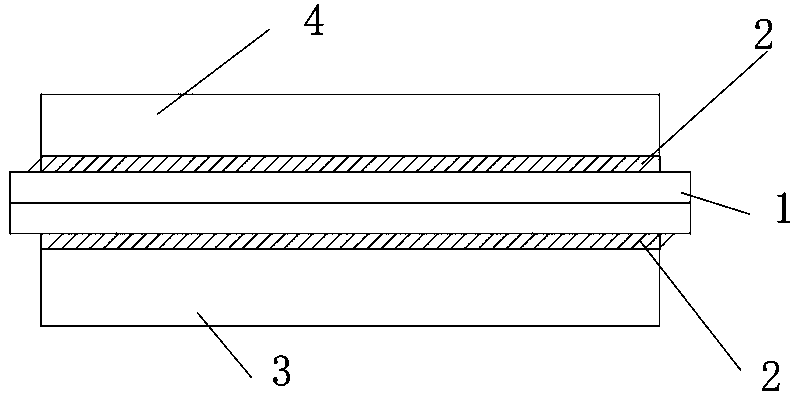

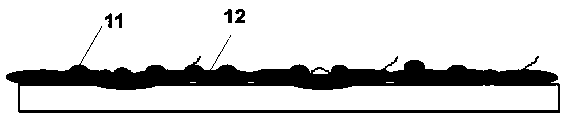

[0025] 2. Use a piece of 40um aluminum-copper composite foil as the bipolar current collector substrate 1, and evenly coat the conductive paste prepared in the previous step on the front and back sides of the bipolar current collector substrate 1 according to a certain surface density. Dry to form a 10um conductive layer 2 to obtain a bipolar current collector, wherein in the conductive layer 2, epoxy resin 12 is evenly coated on one side of the bipolar current collector substrate 1 to form a barrier film, and the graphite 11 is uniform distributed on the surface of the epoxy resin 12.

[0026] 3. Mix lithium manganate, carbon black, and binder in a solvent, stir to obtain a uniformly dispersed slurry, apply it to one side of the conductive layer 2, and dry it to obtain the positive electrode side 3; then zinc pow...

Embodiment 2

[0029] The difference between this embodiment and Example 1 is that when preparing the conductive paste, single-walled carbon nanotubes are used instead of graphite, phenolic resins are used instead of epoxy resins, and the ratio of curing crosslinking agent and solvent is 0.3%, 93.7% (wt%) ); and use 5um aluminum-nickel composite foil instead of 40um aluminum-copper composite foil to make bipolar current collector substrate 1, and the thickness of the formed conductive layer 2 is 0.2um; make the slurry that forms positive electrode side 3 and use manganese dioxide instead of manganese Lithium oxide and carbon fiber instead of carbon black; the slurry for forming the negative electrode side 4 is made of zinc powder coated with pyrolytic carbon instead of zinc powder, and a mixture of graphite and carbon black instead of carbon nanotubes.

Embodiment 3

[0031] The difference between this embodiment and Example 1 is that when preparing the conductive paste, graphite, carbon black, carbon nanotubes, single-walled carbon nanotubes, and carbon fibers are used instead of graphite, and polyurethane is used instead of epoxy resin, and the solidified cross-linked The ratio of coupling agent and solvent is 0.5%, 93.5% (wt%); and the bipolar current collector matrix 1 is made with 10um stainless steel foil instead of 40um aluminum-copper composite foil, and the thickness of the formed conductive layer 2 is 1um; The slurry on the negative electrode side 4 uses activated carbon instead of zinc powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com