Single-layer bismuth tungstate nano-sheet composite photocatalyst modified by carbon quantum dots, preparation method of photocatalyst and application

A technology of carbon quantum dots and bismuth tungstate, applied in the field of single-layer bismuth tungstate nanosheet composite photocatalyst and its preparation, can solve the problems of low light energy efficiency, limited catalytic performance, high probability of surface electron-hole recombination, etc. , to achieve high degradation efficiency, good photocatalytic stability, and good photocatalytic performance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

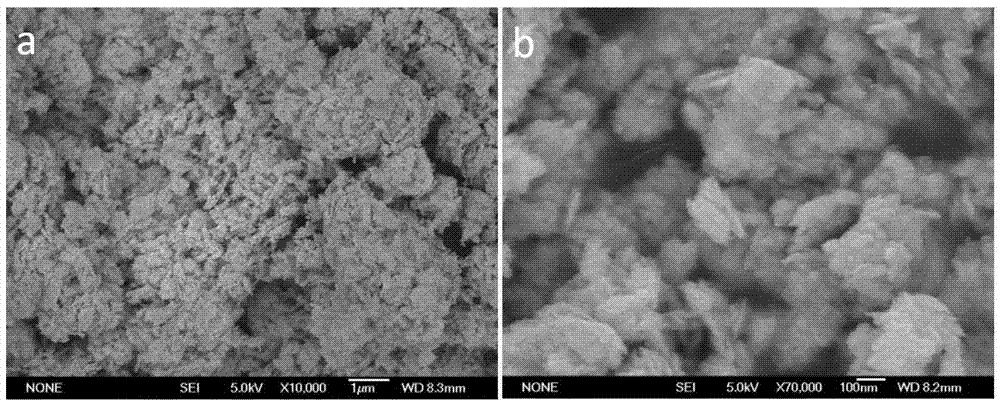

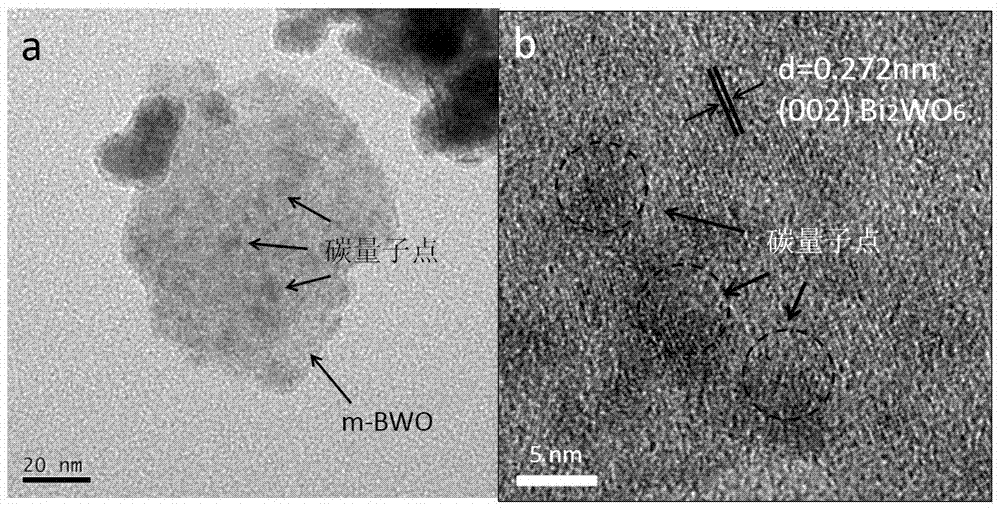

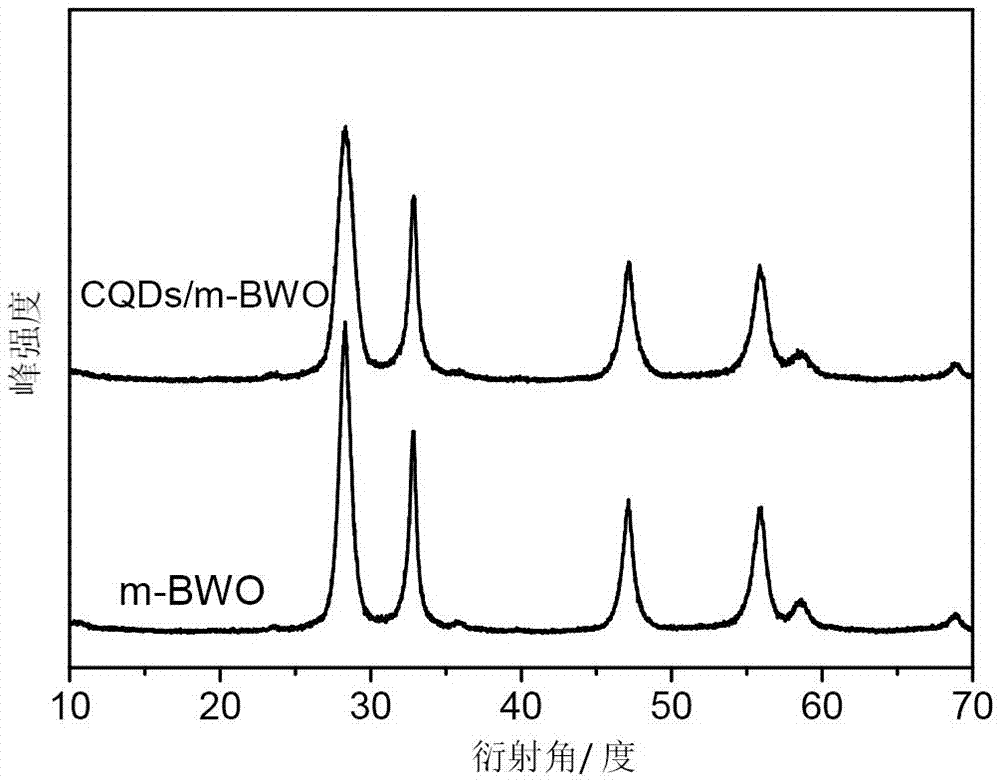

[0045] A carbon quantum dot-modified single-layer bismuth tungstate nanosheet (CQDs / m-BWO) composite photocatalyst, the composite photocatalyst includes a single-layer bismuth tungstate nanosheet and carbon quantum dots (CQDs), in which the single-layer tungstate The bismuth nanosheets are decorated with carbon quantum dots, and the mass ratio of the carbon quantum dots to the single-layer bismuth tungstate nanosheets is 0.03:1.

[0046] A method for preparing the carbon quantum dot-modified single-layer bismuth tungstate nanosheet (CQDs / m-BWO) composite photocatalyst in the present embodiment, comprising the following steps:

[0047] (1) Preparation of carbon quantum dots (CQDs):

[0048] (1.1) Dissolve glucose in deionized water to prepare a glucose solution with a concentration of 0.58M; add 335 μL of ethylenediamine to 10 mL of a glucose solution with a concentration of 0.58M to obtain a transparent precursor solution.

[0049] (1.2) Add the precursor solution in step (1....

Embodiment 2

[0073] The application of a carbon quantum dot-modified single-layer bismuth tungstate nanosheet (CQDs / m-BWO) composite photocatalyst in the treatment of tetracycline hydrochloride wastewater comprises the following steps:

[0074] (1) Weigh 10 mg of carbon quantum dot-modified single-layer bismuth tungstate nanosheets (CQDs / m-BWO) composite photocatalyst prepared in Example 1, and add it to a volume of 100 mL with an initial concentration of 10mg / L tetracycline hydrochloride wastewater to obtain the mixed solution, after adsorption for 0.5h, placed in the photocatalytic reaction device.

[0075] (2) Use a 500W xenon lamp for photocatalytic reaction with a light intensity of 1mw / cm 2 , measure the absorbance value of the reaction solution obtained at different photocatalytic reaction times t (10min, 20min, 30min, 40min, 50min, 60min) at a wavelength of 464nm, and combine the standard curve to obtain the concentration of tetracycline hydrochloride in the reaction solution obtai...

Embodiment 3

[0079] Photocatalytic stability test of carbon quantum dot-modified single-layer bismuth tungstate nanosheets (CQDs / m-BWO) composite photocatalyst:

[0080] (1) After the photocatalytic reaction in Example 2, the carbon quantum dot-modified single-layer bismuth tungstate nanosheet (CQDs / m-BWO) composite photocatalyst was collected by centrifugation, washed with water and ethanol in large quantities, and stored at 60°C The regenerated carbon quantum dots modified single-layer bismuth tungstate nanosheets (CQDs / m-BWO) composite photocatalysts were obtained by drying in an oven for 12 h.

[0081] (2) Weigh 10 mg of the regenerated carbon quantum dot-modified single-layer bismuth tungstate nanosheet (CQDs / m-BWO) composite photocatalyst prepared in step (1), and add it to a volume of 100 mL, the initial The mixed liquid was obtained from tetracycline hydrochloride wastewater with a concentration of 10 mg / L, and was placed in a photocatalytic reaction device after being adsorbed for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com