a kind of sio 2 -c modified al 2 o 3 Carrier and preparation method and application

A carrier and modification technology, which is applied in the direction of hydrogenation preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of difficult control of conditions and complicated preparation process, and achieve the effects of improving anti-hydration performance, promoting hydrolysis and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

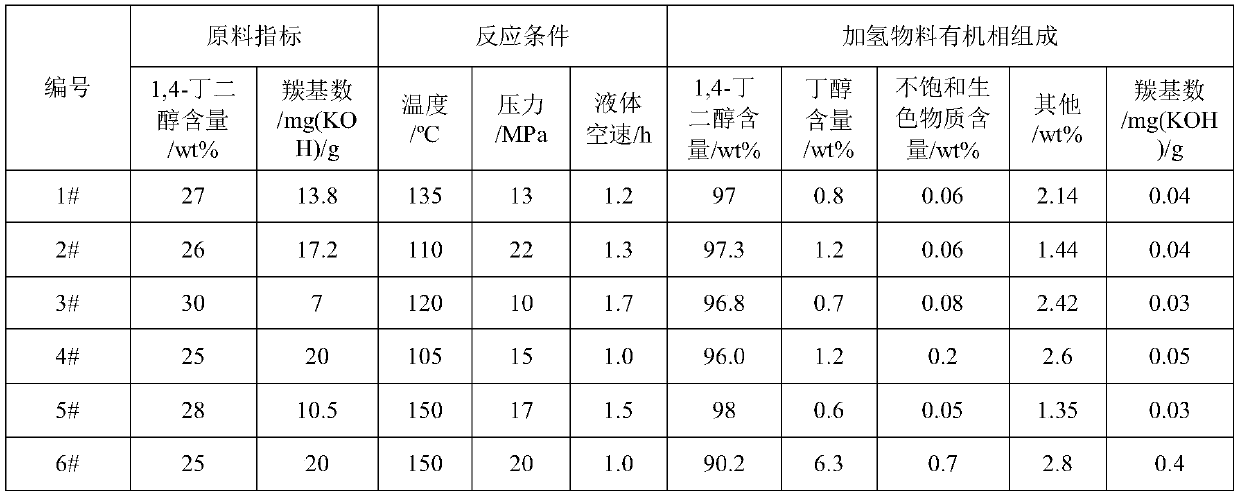

Examples

Embodiment 1

[0025] Take 100g of alumina carrier, steam treatment at 120°C for 0.5h, then vacuum-dry at 30°C for 1h; weigh 1.79g of methyl orthosilicate (containing SiO2 Weight 0.7g), and the sucrose of 0.1g, be dissolved in the methanol-water system of water volume fraction 1%, be mixed with the mixed solution of 50mL, and add formic acid wherein to adjust the pH value of solution at 3; Add the mixed solution prepared Put it into 100g of alumina carrier treated with water vapor, keep it airtight for 1h, and dry at 70°C for 2h; at 450°C, H 2 5% H by volume 2 / N 2 Calcined in mixed atmosphere for 1h to get SiO 2 -C modified Al 2 o 3 Carrier, containing aluminum oxide weight 100g in this carrier, SiO 2 Mass 0.7g, C mass 0.05g, pore volume 1.1mL / g, specific surface area 270m 2 / g, the average pore diameter is 13nm.

[0026] Weigh the above SiO 2 -C / Al 2 o 3 Carrier 100g, weighing 43.08g nickel nitrate hexahydrate, prepared into 80mL impregnating solution, added to the carrier, dried ...

Embodiment 2

[0028] Take 100g of alumina carrier, steam treatment at 200°C for 2h, then vacuum-dry at 50°C for 5h; weigh 53.57g of ethyl orthosilicate (containing SiO 2 Weight 15g), and the glucose of 12g, be dissolved in the ethanol-water system of water volume fraction 10%, be mixed with the mixed solution of 120mL, and add glacial acetic acid wherein to regulate solution pH value at 5; The mixed solution of preparation is added to In the 100g alumina carrier treated with water vapor, keep it airtight for 5 hours, and dry it at a temperature of 200°C for 15 hours; at a temperature of 750°C, H 2 55% H by volume 2 / N 2 Calcined in a mixed atmosphere for 8 hours to obtain SiO 2 -C modified Al 2 o 3 Carrier, containing aluminum oxide weight 100g in this carrier, SiO 2 Mass 15g, C mass 7g, pore volume 0.5mL / g, specific surface area 180m 2 / g, average pore diameter 5nm.

[0029] Weigh the above SiO 2 -C / Al 2 o 3 Carrier 100g, weighing 67.55g nickel nitrate hexahydrate, prepared into ...

Embodiment 3

[0031] Take 100g of alumina carrier, steam treatment at 160°C for 1h, then vacuum-dry at 40°C for 3h; weigh 17.86g of ethyl orthosilicate (containing SiO 2 Weight 5g), and the polyethylene glycol of 3g, be dissolved in the propanol-water system of water volume fraction 5%, be mixed with the mixed solution of 80mL, and wherein add citric acid adjustment solution pH value at 4; The mixed solution was added to 100 g of alumina carriers treated with water vapor, sealed and left for 3 hours, and dried at a temperature of 140°C for 10 hours; at a temperature of 600°C, H 2 40% volume fraction of H 2 / N 2 Calcined in a mixed atmosphere for 5 hours to obtain SiO 2 -C modified Al 2 o 3 Carrier, containing aluminum oxide weight 100g in this carrier, SiO 2 Mass 5g, C mass 1.5g, pore volume 0.8mL / g, specific surface area 220m 2 / g, average pore diameter 9nm.

[0032] Weigh the above SiO 2 -C / Al 2 o 3 100g of the carrier, weighing 108.75g of nickel nitrate hexahydrate, was prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com