Polyimide resin, a preparing method thereof and a polyimide composite material

A technology of polyimide resin and polyimide, applied in its preparation method and polyimide composite material, polyimide resin field, can solve the problem of poor processing performance, heat resistance and resistance of polyimide Problems such as poor solvent resistance and low material utilization rate, etc., achieve excellent mechanical properties, excellent performance, and improve processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of polyimide resin, including the following steps:

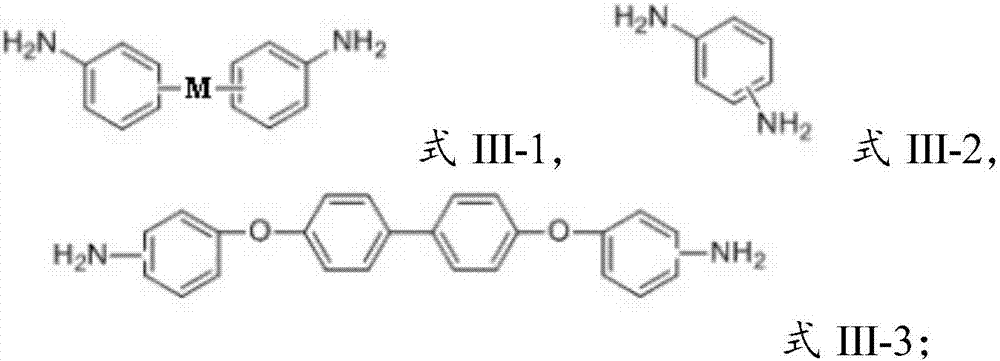

[0055] Mixing aromatic dianhydride and aromatic diamine in an organic solvent to perform imidization reaction to obtain polyimide;

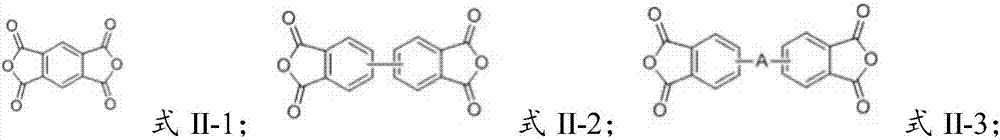

[0056] The aromatic dianhydride includes bisphenol A type diether dianhydride;

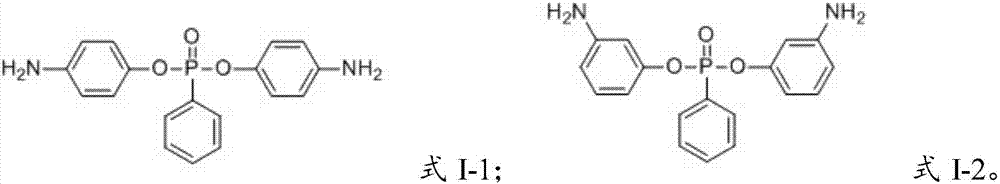

[0057] The aromatic diamine includes bis(aminophenyl) phenylphosphonate.

[0058] In the present invention, it is preferable to dissolve the aromatic dianhydride and the aromatic diamine in an organic solvent to carry out a polymerization reaction to obtain a polyamic acid solution;

[0059] Then the polyamic acid solution is imidized to obtain polyimide.

[0060] In the present invention, the aromatic dianhydride and aromatic diamine are preferably dissolved in an organic solvent, and the polymerization reaction is carried out by means of mechanical stirring. The temperature of the polymerization reaction is preferably -10°C-50°C, more preferably 0- 45°C, most ...

Embodiment 1

[0075] Add 33.334g (0.1075mol) of 4,4'-diphenyl ether dianhydride and 6.215g of bisphenol A diether dianhydride to a three-necked round bottom flask equipped with mechanical stirring, nitrogen protection, water and reflux device. (0.01194mol), 4,4′-diaminodiphenyl ether 21.626g (0.108mol), phenylphosphonic acid bis(p-aminophenyl) ester 4.082g (0.012mol), isophthalic anhydride 0.163g (0.0011mol) , N,N-dimethylacetamide (DMAc) 880g, reacted at room temperature for 5 hours to obtain a polyamic acid solution.

[0076] 500 g of xylene was added to the obtained polyamic acid solution, refluxed with water at 150° C. for 4 hours, and filtered to obtain polyimide powder. The polyimide powder was washed 3 times with acetone, dried at 110° C. for 10 hours, broken through a 100-mesh sieve, and finally light yellow polyimide molding powder was obtained. It was measured that the lowest melt viscosity of the molding powder at 340°C was 2600 Pa·s, the glass transition temperature was 252°C, and...

Embodiment 2

[0078] Into a three-necked round bottom flask equipped with mechanical stirring, nitrogen protection, water and condensing reflux device was added 17.476g (0.0594mol) of 4,4'-biphthalic anhydride, and 30.917g of bisphenol A diether dianhydride ( 0.0594mol), 4,4'-diaminodiphenyl ether 21.626g (0.108mol), phenylphosphonic acid bis(p-aminophenyl) ester 4.082g (0.012mol), phthalic anhydride 0.355g (0.0024mol), 900 g of N,N-dimethylacetamide (DMAc) was reacted at room temperature for 5 hours to obtain a polyamic acid solution.

[0079] 350 g of xylene was added to the obtained polyamic acid solution, refluxed with water at 155°C for 3 hours, and filtered to obtain polyimide powder. The polyimide powder was washed 3 times with acetone, dried at 110° C. for 10 hours, broken through a 100-mesh sieve, and finally light yellow polyimide molding powder was obtained. The lowest melt viscosity of the molding powder at 349°C was measured to be 2450pa·s, the glass transition temperature was 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com