Preparation and application of graphene based metal compound nano array material

A nano-array and graphene-based technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, chemical instruments and methods, etc., can solve problems such as high cost, complex production process, and high energy consumption , to achieve the effect of short time consumption, simple operation stage and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

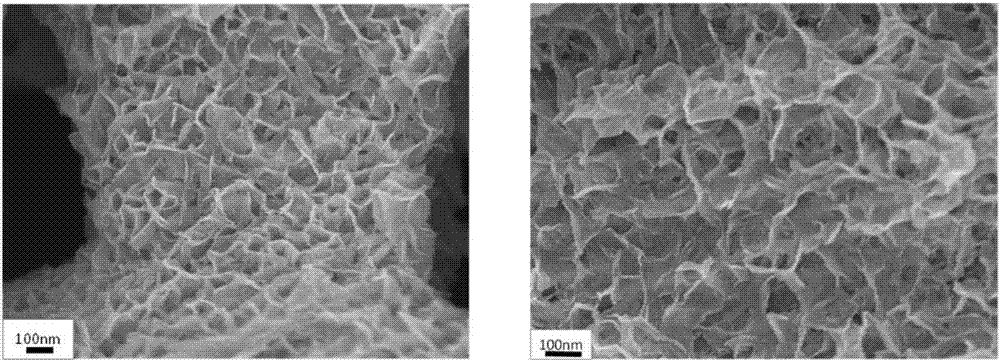

[0043] Take 1.0g 1-ethyl-3-methylimidazole dicyanamide and ZnCl 2 / KCl (4g / 2g) salt mixture was mixed in a mortar and ground evenly. Subsequently, the homogeneously ground slurry was coated on a cleaned nickel foam substrate, followed by heat treatment at 1000° C. for 3 hours in argon. After heat treatment, wash with 0.5M hydrochloric acid aqueous solution, deionized water and absolute ethanol successively. After cleaning, the material was dried in a vacuum oven at 60° C. to collect graphitic carbon nanosheet (CNS) material. The prepared graphene carbon nanosheet (CNS) has a lateral dimension of 100-200 nm, and the CNS is strongly adhered to the nickel foam, and can keep its shape after washing and ultrasonic treatment.

[0044] Put the prepared graphite carbon nanosheets (CNS) in 10mM ferric nitrate solution at room temperature for 48 hours, then take them out, wash them with distilled water and absolute ethanol three times, and dry them to obtain graphene-based metal hydro...

Embodiment 2

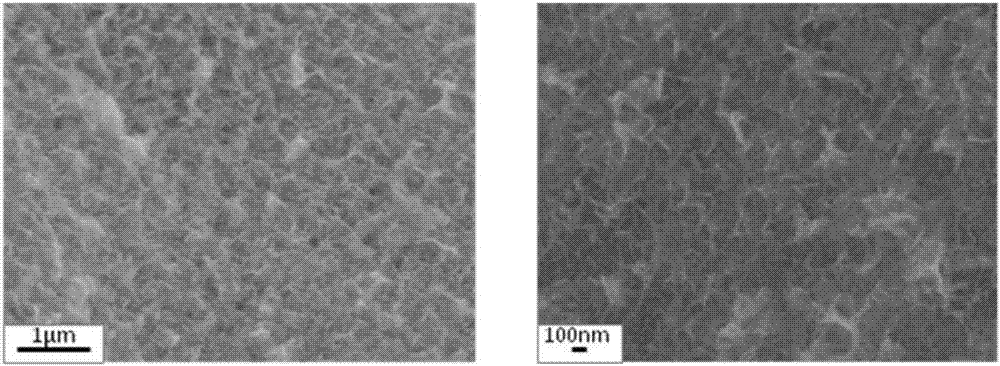

[0047] Take 0.5g 1-ethyl-3-methylimidazole dicyanamide and ZnCl 2 / KCl (2g / 1g) salt mixture was mixed in a mortar and ground evenly. Subsequently, the uniformly ground slurry was coated on a cleaned nickel foam substrate, and then heat-treated at 900° C. for 3 hours under an argon atmosphere. After heat treatment, wash with 0.5M hydrochloric acid aqueous solution, deionized water and absolute ethanol successively. After cleaning, the material was dried in a vacuum oven at 60° C. to collect graphitic carbon nanosheet (CNS) material.

[0048] The prepared graphite carbon nanosheets (CNS) were electrochemically deposited using an electrochemical workstation at room temperature to prepare graphene-based metal hydroxides. Using graphite carbon nanosheets (CNS) as the working electrode, Ag / AgCl as the reference electrode, and nickel coil as the counter electrode, nickel hydroxide nanoparticles were directly deposited on the graphite carbon nanosheets (CNS) in 10mM ferric nitrate s...

Embodiment 3

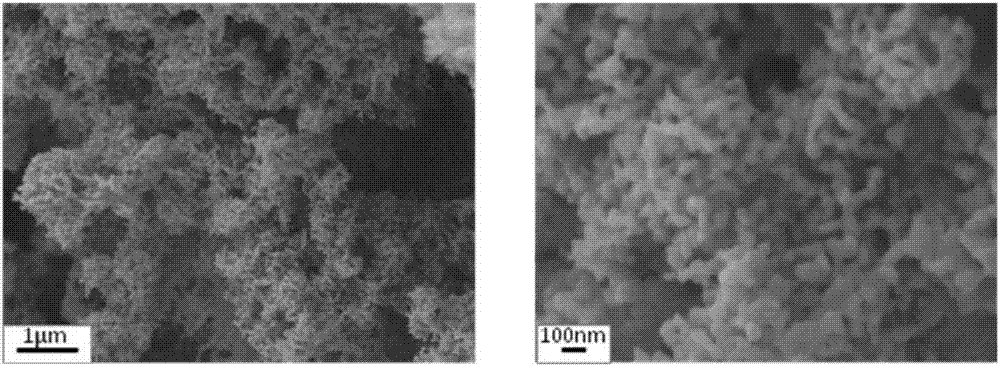

[0051] Take 0.5g 1-ethyl-3-methylimidazole dicyanamide and ZnCl 2 / KCl (2g / 1g) salt mixture was mixed in a mortar and ground evenly. Subsequently, the uniformly ground slurry was coated on a cleaned nickel foam substrate, and then heat-treated at 700° C. for 2 hours in a nitrogen atmosphere. After heat treatment, wash with 0.5M hydrochloric acid aqueous solution, deionized water and absolute ethanol successively. After cleaning, the material was dried in a vacuum oven at 60° C. to collect graphitic carbon nanosheet (CNS) material.

[0052] Place the prepared graphite carbon nanosheets (CNS) at room temperature in a 20mM ferric nitrate solution and seal them, take them out after 24 hours, wash them with distilled water and absolute ethanol three times, and dry them to obtain graphene-based metals. Hydroxide (CNS@FeOOH).

[0053] The prepared graphene-based metal hydroxide (CNS@FeOOH) was calcined in a tube furnace under an ammonia atmosphere, and the temperature was raised t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com