A kind of wear-resistant wood paint and its preparation process

A paint and wood technology, applied in the field of wear-resistant wood paint and its preparation process, can solve the problems of poor water resistance, wear resistance and weather resistance, unobvious wood protection effect, unsatisfactory spraying effect, etc., to achieve gloss Good hardness, improved stain resistance and weather resistance, and excellent fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

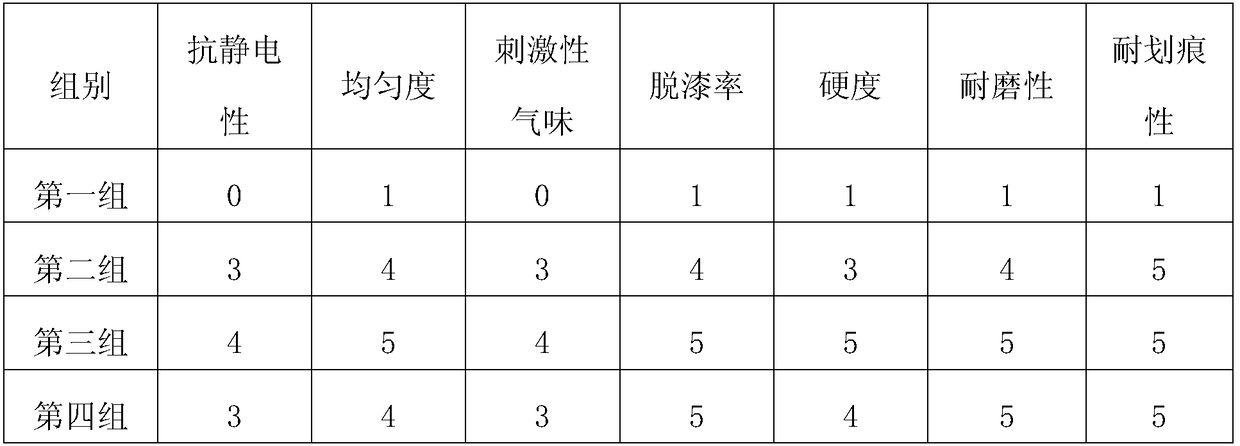

Examples

Embodiment 1

[0031] A kind of wear-resistant wood paint provided by the present embodiment is composed of the following raw materials in parts by weight: 10 parts of wollastonite, 5 parts of montmorillonite, 5 parts of kaolin, 5 parts of talcum powder, 5 parts of rosin resin, and 1 part of polyurethane , 1 part of acrylic resin, 5 parts of auxiliary agents and an appropriate amount of water; wherein the auxiliary agent consists of the following raw materials in parts by weight: 10 parts of camellia oil, 5 parts of calcium carbonate, 5 parts of soybean meal, 1 part of acetone, 1 part of butyl acetate, 1 part of emulsifier, 1 part of moisture-proof agent, 1 part of leveling agent and appropriate amount of water; the emulsifier is castor oil polyoxyethylene ether, and the leveling agent is coconut oil alkylamine.

[0032] The preparation process of the above-mentioned wear-resistant wood paint comprises the following steps:

[0033] (1) preparation additives

[0034] 1) Preparation of raw ma...

Embodiment 2

[0046] A kind of wear-resistant wood paint provided by the present embodiment is composed of the following raw materials in parts by weight: 12 parts of wollastonite, 10 parts of montmorillonite, 7 parts of kaolin, 7 parts of talcum powder, 7 parts of rosin resin, and 3 parts of polyurethane , 3 parts of acrylic resin, 7 parts of auxiliary agents and an appropriate amount of water; wherein, the auxiliary agent is composed of the following raw materials in parts by weight: 12 parts of camellia oil, 10 parts of calcium carbonate, 10 parts of soybean meal, 3 parts of acetone, 3 parts of butyl acetate, 2 parts of emulsifier, 2 parts of moisture-proof agent, 2 parts of leveling agent and appropriate amount of water; the emulsifier is glucoside, and the leveling agent is cocamidopropyl betaine, aluminum distearate and polydimethyl Siloxane is mixed according to the mass ratio of 2:1:1.

[0047] The preparation process of the above-mentioned wear-resistant wood paint comprises the fo...

Embodiment 3

[0061] A kind of wear-resistant wood paint provided by the present embodiment is made up of the following raw materials in parts by weight: 15 parts of wollastonite, 15 parts of montmorillonite, 10 parts of kaolin, 10 parts of talcum powder, 10 parts of rosin resin, and 5 parts of polyurethane , 5 parts of acrylic resin, 10 parts of auxiliary agents and an appropriate amount of water; wherein, the auxiliary agent is composed of the following raw materials in parts by weight: 15 parts of camellia oil, 15 parts of calcium carbonate, 15 parts of soybean meal, 5 parts of acetone, 5 parts of butyl acetate, 3 parts of emulsifier, 3 parts of moisture-proof agent, 3 parts of leveling agent and appropriate amount of water; the emulsifier is polyglycerol ester, the leveling agent is coconut oil alkylamine, aluminum distearate and polydimethylsiloxane according to The mass ratio of 1:3:2 is mixed.

[0062] The preparation process of the above-mentioned wear-resistant wood paint comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com