Nano-hybrided aerogel supercapacitor electrode material and preparation method and application thereof

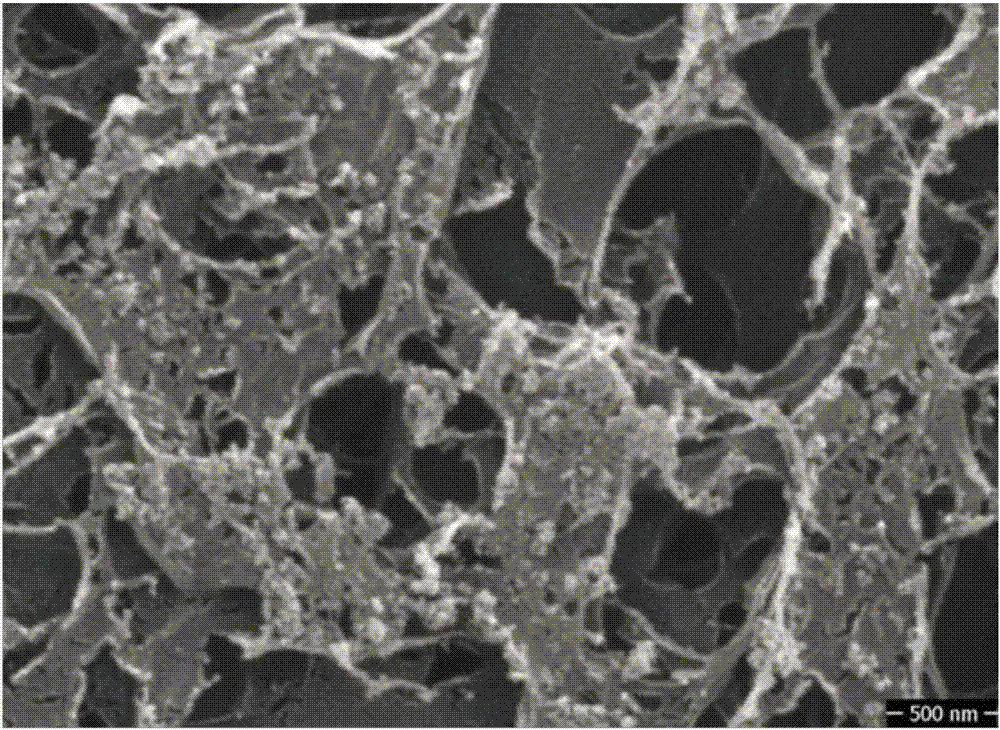

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors. It can solve the problems of low and impossible capacitance of graphene carbon materials and difficult diffusion of electrolyte ions, and achieve excellent electrochemical performance. Performance, performance improvement, effect of tough skeleton structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

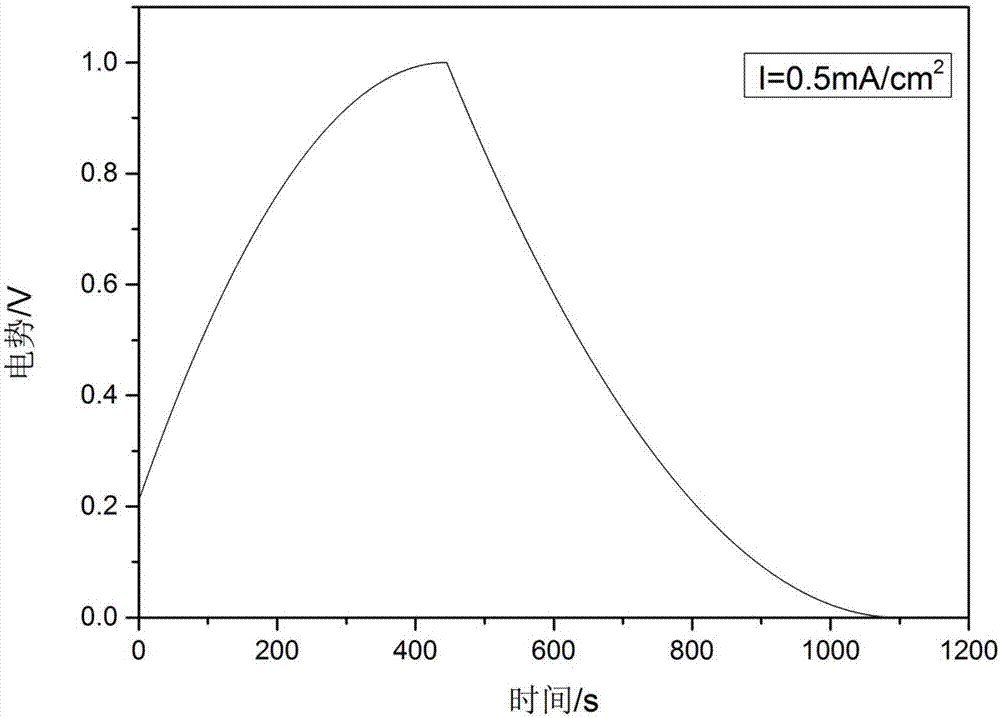

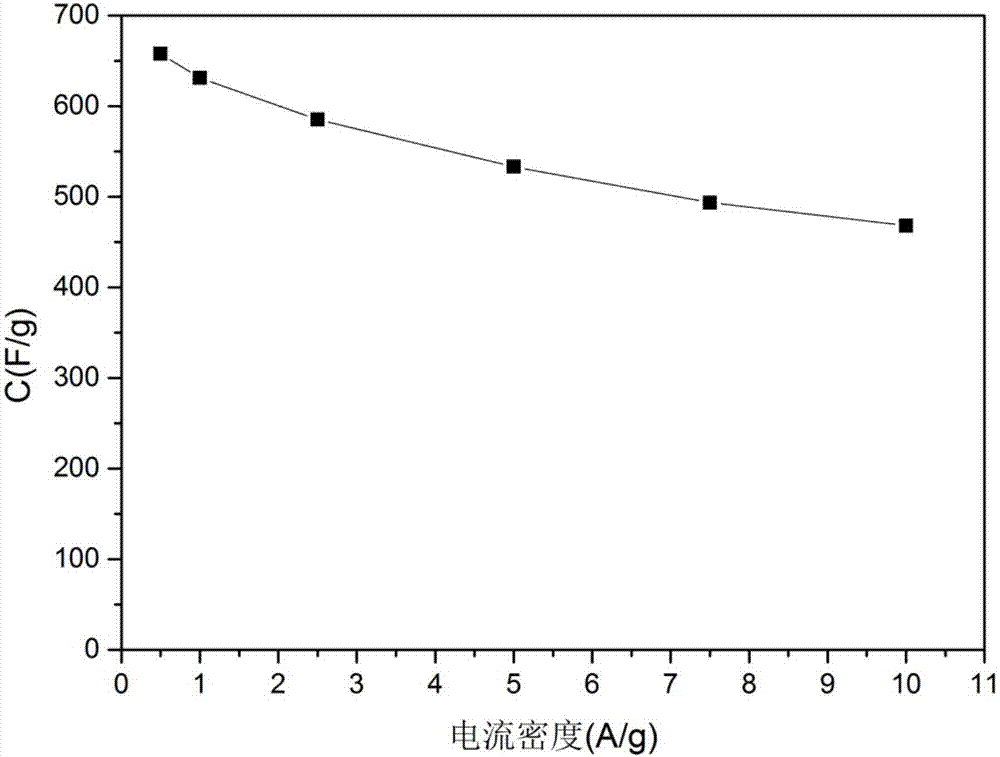

Embodiment 1

[0037] The first step: 1) Weigh 0.05g of TEMPO, add 0.5g of NaBr into 400mL of deionized water in sequence, and stir the above mixture fully with a magnetic stirrer at 10°C; 2) After TEMPO and NaBr are completely dissolved, add Add 10g of wood pulp cellulose that has never been dried in the reaction system; 3) Stir vigorously after the wood pulp cellulose is uniformly dispersed, then add 70g of NaClO to the system, and react by continuously dripping 0.5mol / L NaOH solution The pH of the system is controlled at about 10, until the pH remains substantially constant, and the reaction ends; 4) Wash 3-5 times with deionized water to obtain oxidized cellulose, and then use deionized water to prepare oxidized cellulose into 2 mg / ml slurry, in an ice-water bath, oxidized cellulose was peeled into cellulose nanofibers by ultrasonication at 300W for 20min, and then the prepared cellulose nanofiber suspension was centrifuged at 10000r for 20min to remove unstripped oxidized cellulose, and ...

Embodiment 2

[0045] The first step: 1) Weigh 0.05g of TEMPO, add 0.5g of NaBr into 400mL of deionized water in sequence, and stir the above mixture fully with a magnetic stirrer at 10°C; 2) After TEMPO and NaBr are completely dissolved, add Add 10g of wood pulp cellulose that has never been dried in the reaction system; 3) Stir vigorously after the wood pulp cellulose is uniformly dispersed, then add 70g of NaClO to the system, and react by continuously dripping 0.5mol / L NaOH solution The pH of the system is controlled at about 10, until the pH remains basically unchanged, and the reaction ends; 4) Wash 3-5 times with deionized water to obtain oxidized cellulose, and then use deionized water to prepare oxidized cellulose into 2 mg / ml slurry, in an ice-water bath, oxidized cellulose was peeled into cellulose nanofibers by ultrasonication at 300W for 20min, and then the prepared cellulose nanofiber suspension was centrifuged at 10000r for 20min to remove unstripped oxidized cellulose, and Th...

Embodiment 3

[0053] The first step: 1) Weigh 0.05g of TEMPO, add 0.5g of NaBr into 400mL of deionized water in sequence, and stir the above mixture fully with a magnetic stirrer at 10°C; 2) After TEMPO and NaBr are completely dissolved, add Add 10g of wood pulp cellulose that has never been dried in the reaction system; 3) Stir vigorously after the wood pulp cellulose is uniformly dispersed, then add 70g of NaClO to the system, and react by continuously dripping 0.5mol / L NaOH solution The pH of the system is controlled at about 10, until the pH remains basically unchanged, and the reaction ends; 4) Wash 3-5 times with deionized water to obtain oxidized cellulose, and then use deionized water to prepare oxidized cellulose into 2 mg / ml slurry, in an ice-water bath, oxidized cellulose was peeled into cellulose nanofibers by ultrasonication at 300W for 20min, and then the prepared cellulose nanofiber suspension was centrifuged at 10000r for 20min to remove unstripped oxidized cellulose, and Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com