Mercury ion adsorbent preparation method

An adsorbent and mercury ion technology, applied in the field of preparation of mercury ion adsorbents, can solve problems such as mercury ion pollution, and achieve the effects of simple and easy process steps, strong acid resistance and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In specific implementation process, the preparation method of mercury ion adsorbent of the present invention comprises the following steps:

[0027] (1) Firstly, diatomite is ground into powder, and after being treated with a 200-mesh standard sieve, sulfuric acid with a concentration of 40wt% is added at a solid-to-liquid ratio of 1:4, mechanically stirred, heated at 80°C, treated for 8h, and then distilled water Wash until neutral, filter with suction, dry in a drying oven at 50-100°C for 24 hours, and finally put it in a muffle furnace at 450°C, heat for 4 hours and seal it for later use.

[0028] (2) In a round-bottomed flask, take 50ml of ethanol solution with a volume fraction of 80% as a solvent, add 1-6g of refined diatomaceous earth, disperse ultrasonically for 30min, and add a certain amount of amino coupling agent under vacuum or nitrogen protection , reacted at 45°C for 12h, washed with ethanol, dried by suction filtration, put into an oven at 45°C, and drie...

Embodiment 1

[0048] In the present embodiment, the preparation method of mercury ion adsorbent is as follows:

[0049] (1) First, diatomite is ground into powder, sieved through a 200-mesh standard sampling sieve, then adding sulfuric acid with a concentration of 40wt% according to a solid-to-liquid ratio of 1:4, mechanically stirring, heating at 80°C, and treating for 8h, then using Wash with distilled water until it is neutral, filter it with suction, put it in a drying oven at 50-100°C for 24 hours, and finally put it in a muffle furnace at 450°C, heat it for 4 hours to form refined diatomite and seal it for later use;

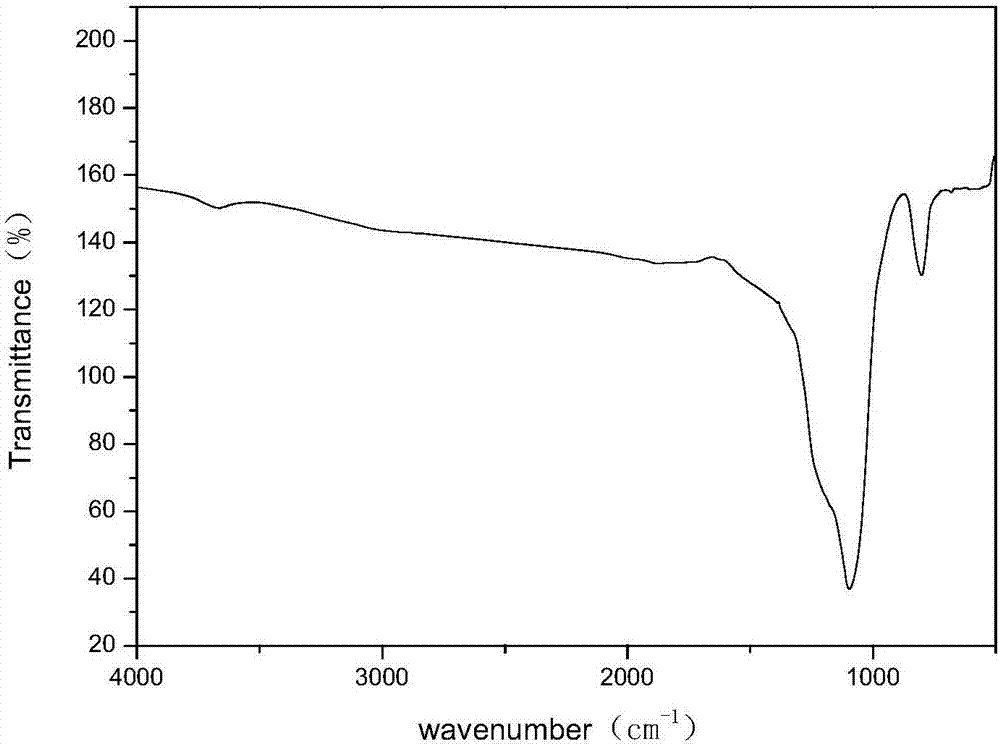

[0050] Such as figure 1 As shown, it can be seen from the FT-IR spectrum of refined diatomite that at 3660cm -1 The broad peak at is attributed to the Si-OH antisymmetric stretching vibration at 1090cm -1 The asymmetric strong absorption broadband at is attributed to Si-O antisymmetric stretching vibration, 800cm -1 The place is Si-O symmetric stretching vibration, w...

Embodiment 2

[0055] In the present embodiment, the preparation method of mercury ion adsorbent is as follows:

[0056] (1) is synthetically identical with step (1) in embodiment 1;

[0057] (2) In a round bottom flask, take 50ml of ethanol solution with a volume fraction of 80% as a solvent, add 5g of refined diatomaceous earth, and ultrasonically disperse for 30min. Under vacuum or nitrogen protection, add 2ml of amino coupling agent KH550, React at 45°C for 12h, wash with ethanol, filter and dry, put in an oven at 45°C, and dry in vacuum for 24h to form amino-modified diatomaceous earth.

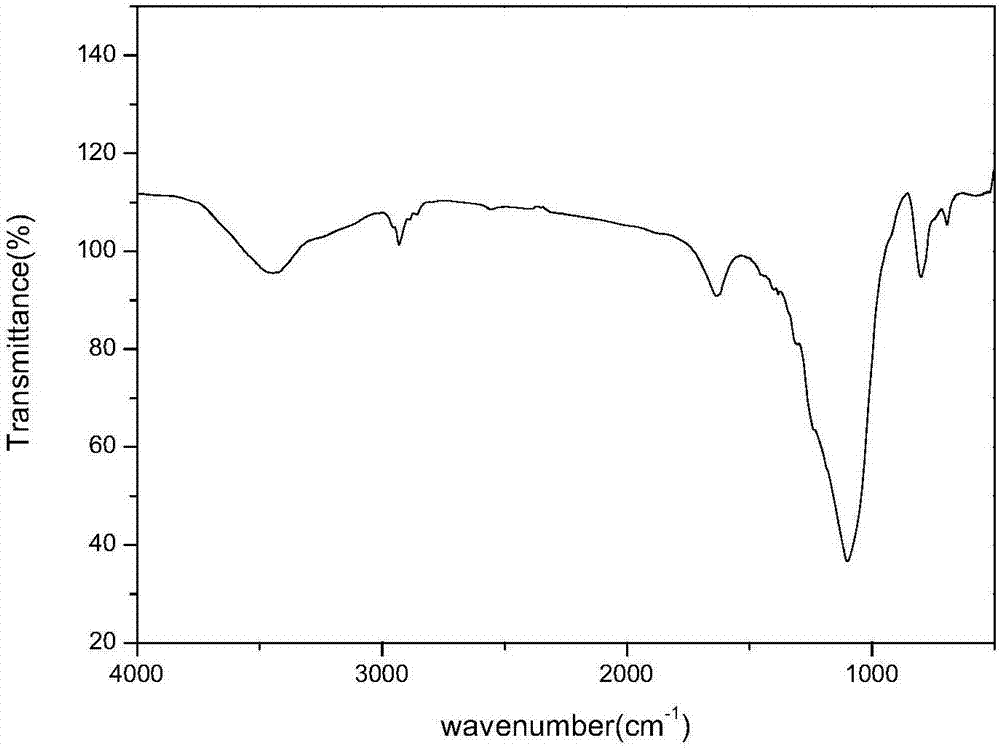

[0058] Such as figure 2 As shown, it can be seen from the FT-IR spectrum of amino-modified diatomaceous earth that at 3450cm -1 The N-H stretching vibration peak appears at 2938, the C-H stretching vibration peak appears at 2938 and the 1637cm -1 N-H scissor vibration peak appears at 691cm -1 N-H non-planar bending vibration peaks appear at , and these characteristic peaks indicate that amino grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com