Catalyst for synthesizing dimethyl oxalate by CO as well as preparation method and application of catalyst

A technology of dimethyl oxalate and catalyst, which is applied in the field of catalyst and its preparation for synthesizing dimethyl oxalate with CO, can solve the problems of unresolved Cl ion corrosion, low selectivity of target products, high production cost, etc., and solve equipment corrosion , Solubility improvement, and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

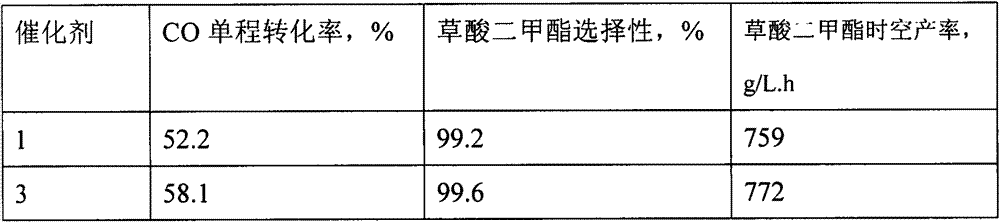

Examples

preparation example Construction

[0023] The preparation method of this catalyst is made up of the following steps: 1. The acetate of metal strontium or barium and water are made into the acetate aqueous solution, and the concentration of the acetate aqueous solution is 0.002~0.2mol / L, and the carrier is heated at a temperature of Immerse in acetate aqueous solution at 40-60°C for 10-24 hours, then dry at 100-120°C for 4-8 hours to obtain the first solid, in which metal strontium or barium acetate and water are formulated into vinegar Aqueous salt solution refers to the acetate aqueous solution made of metal strontium acetate and water or the acetate aqueous solution made of metal barium acetate and water; 2. The metal palladium acetate or oxalic acid The salt is added with water to prepare an aqueous solution, the concentration of the aqueous solution is 0.01-0.3mol / L, then a water-soluble organic polymer is added to the aqueous solution to form a mixed solution, and the amount of the water-soluble organic pol...

Embodiment 1

[0035] Make an aqueous solution of strontium acetate and deionized water, the concentration of the aqueous solution is 0.5M, and the specific surface area is 275m 2 / g Al 2 o 3 Immerse in this solution for 12 hours at 50°C, and then dry at 100°C for 7 hours to obtain a solid; make an aqueous solution of palladium acetate, acetic acid and deionized water with a concentration of 0.08M, and then add polyvinyl alcohol to achieve a concentration of 6.5% of this aqueous solution; the solid impregnated with strontium was immersed in this solution for 12 hours, and then dried at 100°C for 5 hours and then taken out to obtain a solid; the fixed object was deionized with deionized water at room temperature After washing for 8 hours, it was dried at 105°C for 10 hours and calcined at 410°C for 14 hours to obtain catalyst 1.

[0036] The aqueous solution after washing at room temperature and the aqueous solution obtained by soaking strontium are subjected to normal pressure distillation...

Embodiment 2

[0038] Make an aqueous solution of barium acetate and deionized water, the concentration of the aqueous solution is 0.15M, and the specific surface area is 275m 2 / g Al 2 o 3 Immerse in this solution for 22 hours at 60°C, and then dry at 110°C for 5 hours to obtain a solid; make an aqueous solution of palladium acetate, acetic acid and deionized water at a concentration of 0.2M, and then add polyacrylamine to a concentration of 7.5% of this aqueous solution; soak the solid object impregnated with barium in this solution for 9 hours, then dry it at 110°C for 6 hours and take it out to obtain a solid object; put the fixed object at room temperature with deionized water After washing for 6 hours, it was dried at 115°C for 9 hours and calcined at 450°C for 12 hours to obtain catalyst 2.

[0039] The aqueous solution after washing at room temperature and the aqueous solution obtained by soaking barium are subjected to normal pressure distillation to separate polyacrylamine and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com