Electrocatalytic oxidation water treatment device and method for treatment of hardly degradable organic wastewater

A technology of electrocatalytic oxidation and water treatment equipment, which is applied in the direction of oxidized water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve problems such as high operating costs, limitations of electrochemical methods, and high unit power consumption. Achieve the effect of simple device structure design, reasonable operating cost and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present invention handles the method for refractory organic waste water, and this embodiment is the treatment of organic cyanide-containing waste water to gold extraction, dressing and smelting. The water quality and quantity of this organic waste water are: water quantity 100t / d, water quality condition COD: 10440mg / L, TCN: 5760mg / L, Cu: 3350mg / L, Zn: 1310mg / L, Fe: 690mg / L, pH 11. The processing steps include:

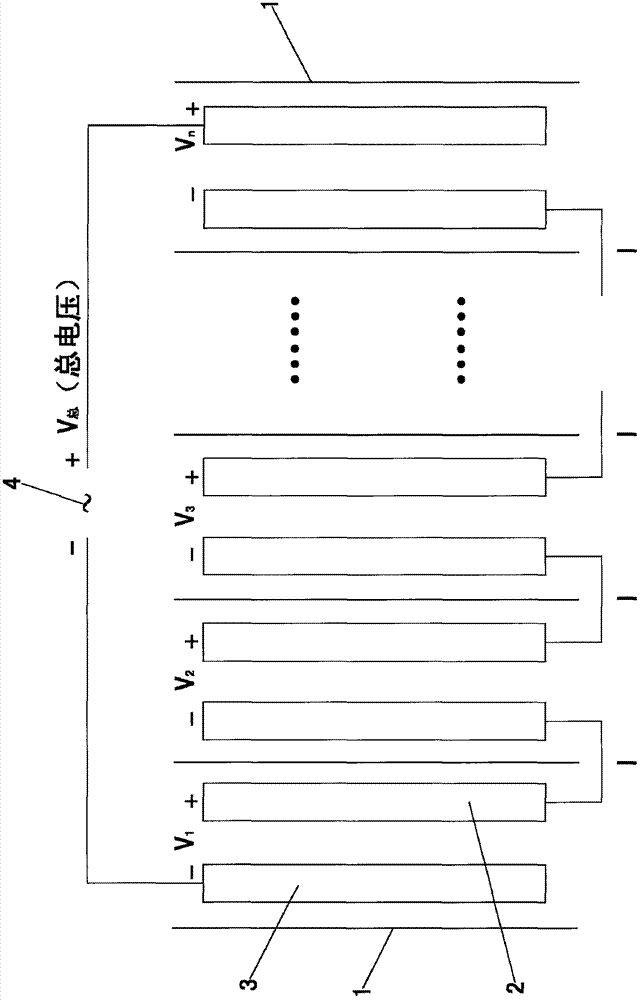

[0044] (1) The pH value of the wastewater discharged from the gold-extracting cyanide-containing wastewater is about 11, filtered to make the average value of the wastewater, and directly enters the electrocatalytic oxidation water treatment device, combined with figure 1 As shown, the device includes at least two electrolytic cells 1 connected to each other. An anode electrode plate 2 and a cathode electrode plate 3 are respectively arranged in each electrolytic cell 1. Each anode electrode plate 2 is connected to the positive pole of a power supply 4, and...

Embodiment 2

[0054] The present invention handles the method for refractory organic waste water, and this embodiment is to plastic regenerated waste water treatment, and its main pollutant has: pH value is 7~8, CODcr fluctuates in the range of 2000~4000mg / L, SS is in 8000~10000mg / L Fluctuations within the L range, surfactants, a small amount of metal ions and non-metal ions, etc., the present embodiment adopts two-stage advanced treatment by electrochemical method, and the processing steps include:

[0055] (1) The pH value of the waste water discharged from plastic regeneration waste water is about 7.7, filtered to make the waste water average, and directly enters the electrocatalytic oxidation water treatment device, combined with figure 1 As shown, the device includes at least two electrolytic cells 1 connected to each other. An anode electrode plate 2 and a cathode electrode plate 3 are respectively arranged in each electrolytic cell 1. Each anode electrode plate 2 is connected to the p...

Embodiment 3

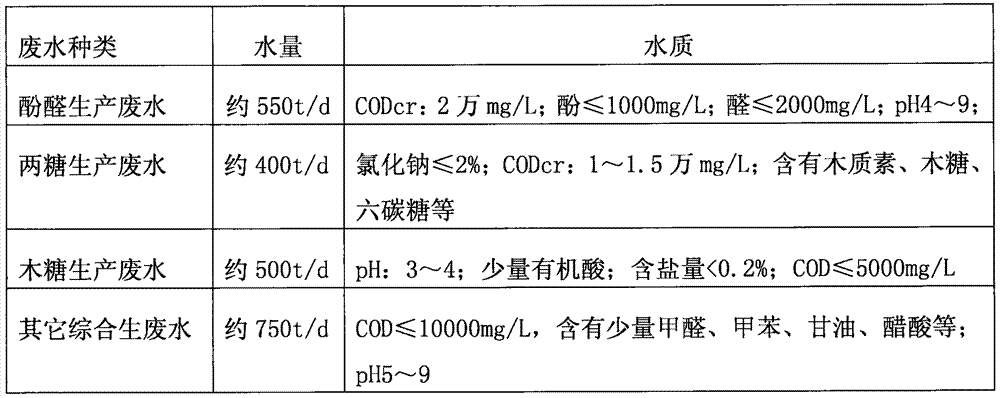

[0062] The method of the present invention for treating refractory organic waste water, this embodiment is for a certain Shandong Group Co., Ltd. (the existing five major industries are respectively building energy-saving products, industrial phenolic formaldehyde, casting materials, biomass energy and biomass chemical industry, food and medicine) The original organic wastewater treatment, the water quality is as follows:

[0063]

[0064] The biochemical treatment of the above organic wastewater does not meet the standard, and the electrochemical method of Embodiment 2 is also used for two-stage advanced treatment, so that the COD of the above organic wastewater can be stably reduced to below 50mg / L. The removal rate of COD concentration reaches the national discharge standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com