Method for regulating and controlling disodium guanylate crystallization process through oil separation and transformation

A technology of disodium guanylate and hydrochloric acid, applied in organic chemistry methods, chemical instruments and methods, organic chemistry and other directions, can solve the problems of ethanol residue, methanol toxicity, high solubility, etc., and achieve low residual amount, uniform particle size, high Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Pour 1.1 times isopropanol into 100ml of 5'-guanylate disodium solution with a stirring intensity of 300rpm, pH=9.8, and a concentration of 150g / L, and the system is in an oily state;

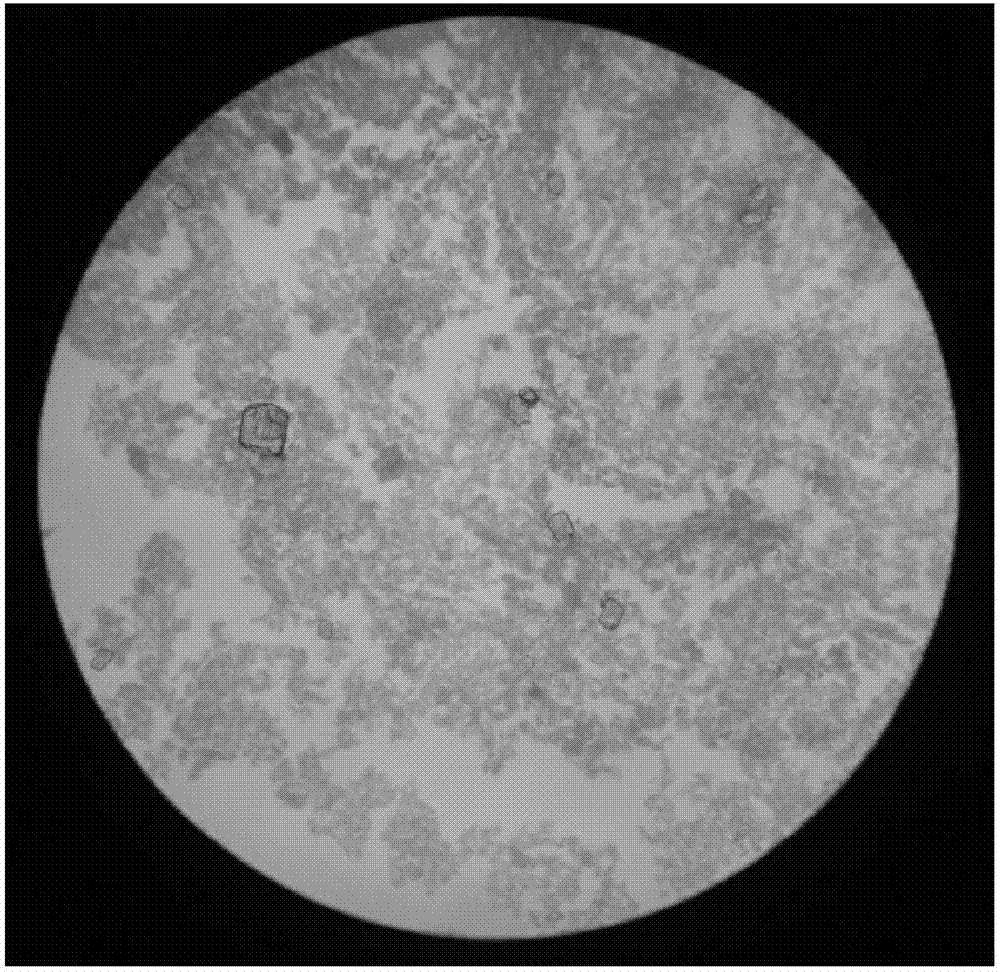

[0035] Step 2: Add 0.45g I-type 5'-guanylate disodium crystals to the mixed solution obtained in Step 1 as a seed crystal, and the crystal status in the system is as follows: figure 1 As shown, start to add pH=7.5 dropwise at a rate of 5% per hour of the volume of the disodium guanylate aqueous solution of pH=9.8, and the concentration is 30ml of 5’-disodium guanylate solution of 150g / L;

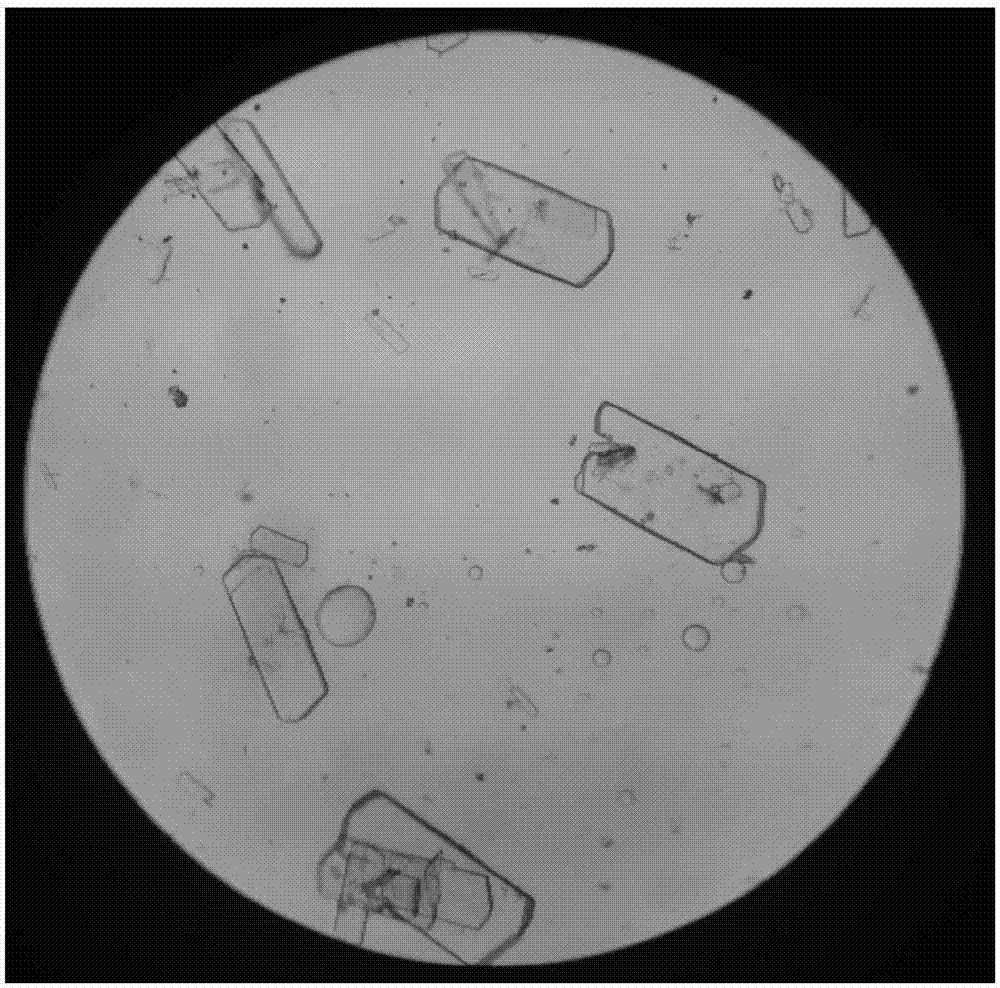

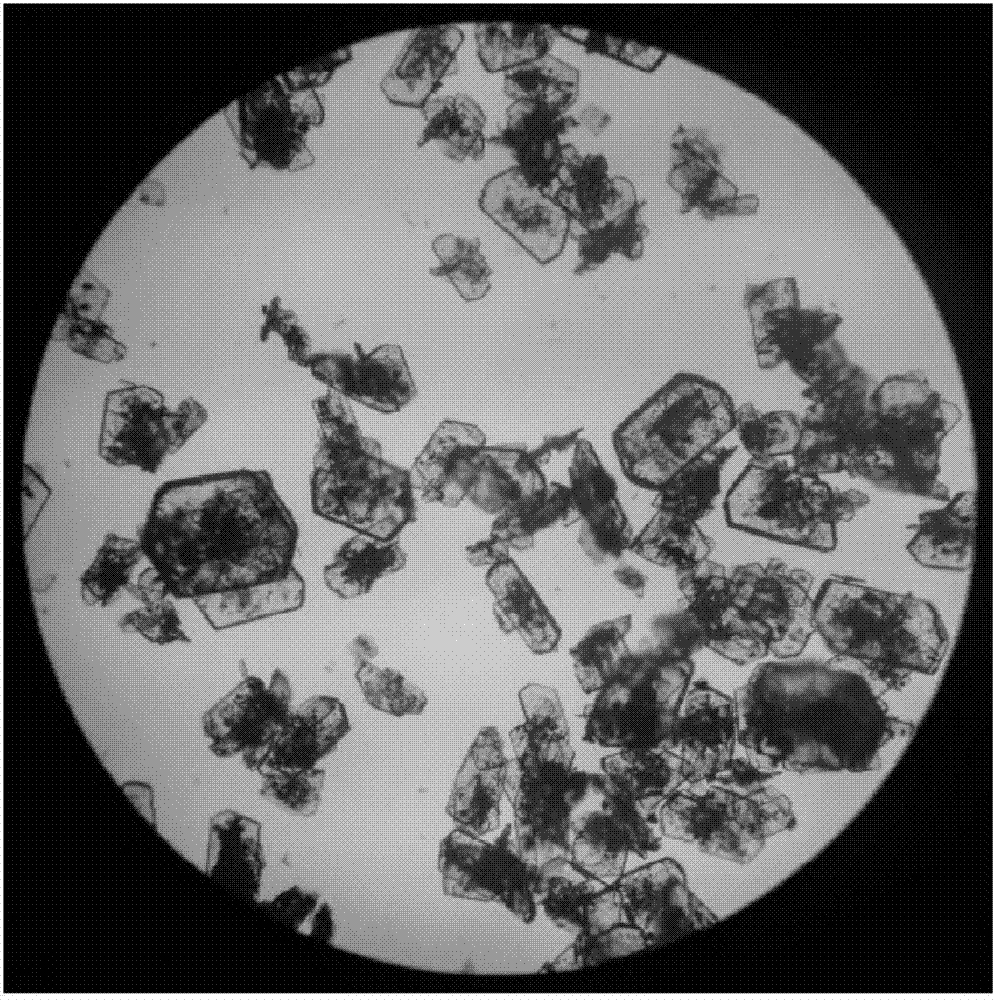

[0036] Step 3: Add 25ml isopropanol and 20ml 0.5mol / L hydrochloric acid mixed solution ( figure 2 shown), while slowly cooling down to 10°C ( Figure 4 Shown), suction filtration, drying to obtain type I 5 '- disodium guanylate crystal product.

[0037] The product purity is: 99.4%, the yield is: 99.0%, and the light transmittance is 99.3%. According to the method, the final product obtained...

Embodiment 2

[0039] Step 1: Pour 0.9 times isopropanol into 100ml of 5'-guanylate disodium solution with a stirring intensity of 200rpm, pH=10.0, and a concentration of 150g / L, and the system is in an oily state;

[0040] Step 2: Add 0.45 g of I-type 5'-disodium guanylate crystals to the mixed solution obtained in step 1 as a seed crystal, and start to add dropwise at a rate of 6% per hour of the volume of the disodium guanylate aqueous solution at pH=10.0 25ml of 5'-guanylate disodium solution with pH=7.5 and a concentration of 150g / L;

[0041] Step 3: After step 2, add 45ml of isopropanol and 30ml of 0.5mol / L hydrochloric acid mixed solution dropwise at a rate of 7% per hour of the volume of the disodium guanylate aqueous solution with pH=9.8, while slowly cooling down to 5°C for suction filtration, Dry to obtain type I 5'-guanylate disodium crystal product.

[0042] Product purity: 99.2%, yield: 99.1%, light transmittance: 99.2%.

Embodiment 3

[0044] Step 1: Pour 1.1 times of isopropanol into 100ml of 5'-guanylate disodium solution with a stirring intensity of 150rpm, pH=9.8, and a concentration of 200g / L, and the system is in an oily state;

[0045] Step 2: Add 0.35 g of type I 5'-disodium guanylate crystals to the mixed solution obtained in step 1 as a seed crystal, and start to add dropwise at a rate of 6% per hour of the volume of the disodium guanylate aqueous solution with pH=9.8 pH=7.7, 40ml 5'-guanylate disodium solution with a concentration of 200g / L;

[0046] Step 3: After step 2 is completed, add 30ml of isopropanol and 23ml of 0.6mol / L hydrochloric acid mixed solution dropwise at a rate of 7% per hour of the volume of the disodium guanylate aqueous solution with pH = 9.8, while slowly cooling down to 10°C for suction filtration, Dry to obtain type I 5'-guanylate disodium crystal product.

[0047] The product purity is: 99.0%, the yield is: 98.3%, and the light transmittance is 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com