Printing material of printing film and preparation method

A printing material, printing film technology, applied in conductive coatings, carboxyl rubber coatings, paints containing biocides, etc., can solve the problems of no peeling force of the ink layer, high resin brittleness, poor hydrophilicity, etc., to achieve good economic and social benefits, excellent pulverization resistance, excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

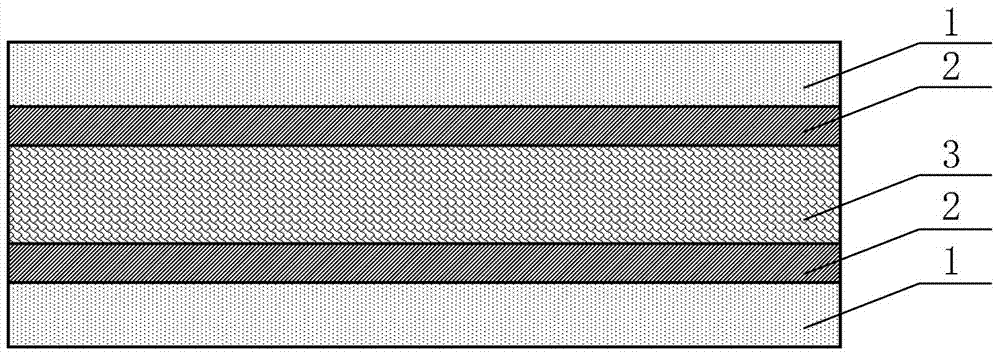

[0060] A kind of preparation method of printing film class, described antistatic coating 2 comprises following preparation method:

[0061] A), in the water-based carboxy-modified styrene-butadiene latex, slowly mix polyaniline antistatic agent, stir 1 hour under 500rpm rotating speed, the material is mixed evenly;

[0062] B), then slowly add the diluted leveling agent and defoamer, and stir at a low speed for 20 minutes;

[0063] Add a small amount of leveling agent to adjust the surface tension of the coating to ≦30mN / m at 20°C, which is slightly lower than the surface tension of the PET substrate; control the solid content of the coating to 15%, and the viscosity to 150cps to meet the extrusion slope Process requirements for flow coating method;

[0064] C), finally adjust the viscosity of the coating to be 100cps, filter through a 300-mesh filter, and let it stand for defoaming;

[0065] Carboxyl-modified waterborne styrene-butadiene latex is selected as the film-formin...

Embodiment 1

[0083] Embodiment 1, the coating formula of antistatic coating 2, is made up of following raw materials according to weight parts: 95 parts of carboxy-modified water-based styrene-butadiene latex; 2 parts of polyaniline antistatic agent; 0.1 part of leveling agent; defoamer 0.1 part; 92 parts of water;

[0084] The coating formula of printing coating 1 is composed of the following raw materials according to parts by weight: 35 parts of acrylic modified polyurethane emulsion; 12 parts of silica sol; 20 parts of water; 10 parts of ethanol; 0.5 parts of leveling agent; 0.5 parts of defoaming agent;

[0085] The acrylic modified polyurethane emulsion includes a prepolymer and an emulsion. The prepolymer is a prepolymer of the polyurethane segment. The formula of the prepolymer consists of the following raw materials in parts by weight: 35 parts of diphenylmethane diisocyanate; 32 parts of polytetrahydrofuran diol 2.5 parts of triethylamine; 5 parts of dimethylolbutyric acid; 0.15 ...

Embodiment 2

[0086] Embodiment 2, the coating formula of antistatic coating 2, is made up of following raw material according to weight parts: 100 parts of carboxy-modified water-based styrene-butadiene latex; 5 parts of polyaniline antistatic agent; 0.1 part of leveling agent; defoamer 0.1 part; 95 parts of water;

[0087] The paint formula of printing coating 1 is composed of the following raw materials according to parts by weight: 40 parts of acrylic modified polyurethane emulsion; 14 parts of silica sol; 20 parts of water; 10 parts of ethanol; 0.5 parts of leveling agent; 0.5 parts of defoaming agent;

[0088] The acrylic modified polyurethane emulsion includes a prepolymer and an emulsion. The prepolymer is a prepolymer of the polyurethane segment. The formula of the prepolymer consists of the following raw materials in parts by weight: 40 parts of diphenylmethane diisocyanate; 40 parts of polytetrahydrofuran diol 2.5 parts of triethylamine; 9 parts of dimethylolbutyric acid; 0.15 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com