Synthesis method and application of monodisperse high-catalytic-performance solution-state silver nanoparticles

A technology of silver nanoparticles and nanoparticles, which is applied in the field of preparation of noble metal nanosystems, can solve the problems of high surface energy and aggregation of silver nanoparticles, limited applications, etc., and achieve high catalytic performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

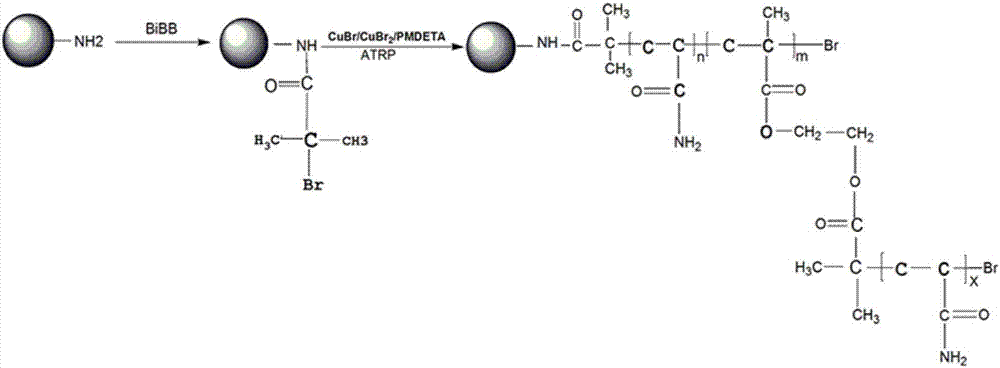

[0027] The preparation synthesis of solution state silver nanoparticles of the present invention is summarized as follows:

[0028] (1) Synthesis of brominated silica nanoparticles;

[0029] (2) SiO 2 - BIEM-PAM nanoparticle synthesis;

[0030] (3) Using silver nitrate as a silver ion donor and sodium borohydride as a reducing agent on SiO 2 - Synthesis of silver nanoparticles in aqueous solution of BIEM-PAM nanoparticles;

[0031] (4) Remove SiO in the mixed solution by centrifugation 2 - BIEM-PAM nanoparticles to obtain silver nanoparticles in solution.

[0032] The specific preferred steps are as follows, but not limited thereto, and all methods to achieve the object of the present invention use the present invention.

[0033] The method of described step (1) is as follows:

[0034] Take ammoniated silicon dioxide nanoparticles and wash them with tetrahydrofuran for 3 to 5 times; add ammoniated silicon dioxide, triethylamine and tetrahydrofuran in sequence, and contro...

Embodiment 1

[0043] Example 1: SiO 2 - Preparation of BIEM-PAM nanoparticles.

[0044] Take ammoniated silica nanoparticles and wash them 3 times with tetrahydrofuran; add ammoniated silica, triethylamine and tetrahydrofuran in sequence, and the mass ratio of silica to tetrahydrofuran is 0.08997:1, the mass ratio of triethylamine to tetrahydrofuran 0.02737:1, stirred for 30 minutes; stirred under ice bath for 15 minutes, then added the mixed solution of 2-bromoisobutyryl bromide and tetrahydrofuran using a constant pressure titration funnel, wherein the mass ratio of 2-bromoisobutyryl bromide and tetrahydrofuran was controlled to be 0.6972 : 1, adjust the constant pressure funnel piston to make the solution in the funnel drop off within 30min, and seal the flask; the mixed solution is stirred in an ice bath for 2h, then the system is placed in a 30°C water bath for 20h; after the end, the reactant is taken out Wash by centrifugation, wash with THF 3 times, ethanol 3 times, water 3 times a...

Embodiment 2

[0047] Example 2: SiO 2 - Preparation of BIEM-PAM nanoparticles.

[0048] Take ammoniated silica nanoparticles and wash them with tetrahydrofuran 4 times; add ammoniated silica, triethylamine and tetrahydrofuran in sequence, and the mass ratio of ammoniated silica and tetrahydrofuran is controlled at 0.08:1, triethylamine and The mass ratio of tetrahydrofuran is controlled at 0.02:1, stirred for 40min; stirred under ice bath for 20min, then utilizes constant pressure titration funnel to add the mixed solution of 2-bromoisobutyryl bromide and tetrahydrofuran, wherein 2-bromoisobutyryl bromide and tetrahydrofuran The mass ratio is controlled at 0.6:1, and the constant pressure funnel piston is adjusted so that the solution in the funnel drops within 40 minutes, and the flask is sealed; the mixed solution is stirred in an ice bath for 2.5 hours, and then the system is placed in a 30°C water bath for 25 hours; end Afterwards, the reactant was taken out and washed by centrifugatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com