A preparing method and uses of a hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of amino hydroxyl compounds, etc., can solve the adverse effects of loss, reduction of aminophenol selectivity, catalyst service life and production cost control, etc. problems, to achieve the effect of low cost, simple process and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Cerium oxide (CeO 2 ) The carrier is crushed and sieved, and 20-40 meshes are selected, and an equal volume of nickel nitrate aqueous solution is impregnated to obtain a sample with a nickel loading of 6wt.%. Calcined at 450°C for 4 hours to obtain ceria-supported nickel oxide (NiO / CeO 2 );

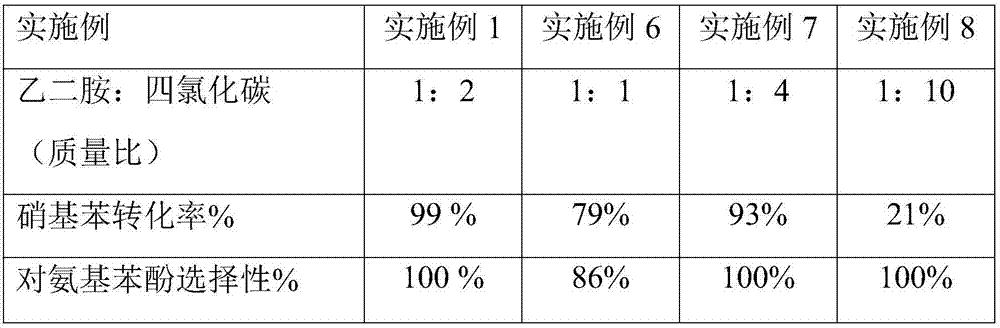

[0024] (2) Take 1g NiO / CeO 2 Put it into a round-bottomed flask, add 2.0g ethylenediamine, 4.0g carbon tetrachloride and 80mL xylene in sequence, first raise the temperature to 90°C for 4 hours, then raise the temperature to 140°C and continue the reaction for 4 hours, then stop heating and wait to cool to After room temperature, the precipitate was separated by centrifugation and dried, and ground to obtain a powdery product;

[0025] (3) Then calcined at 600°C for 6 hours in a nitrogen atmosphere to obtain a black powder catalyst (CN / Ni / CeO 2 ).

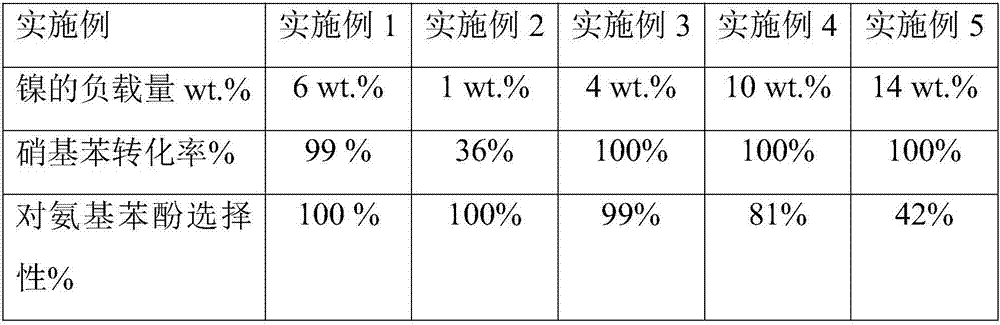

[0026] It is used to catalyze the hydrogenation of nitrobenzene to synthesize p-aminophenol, and the conversion rate of nitro...

Embodiment 12

[0037] (1) Cerium oxide (CeO 2 ) The carrier is crushed and sieved, and 20-40 mesh is selected, and an equal volume of nickel nitrate solution is impregnated to obtain a sample with a nickel loading of 6wt.%. Calcined at 450°C for 4 hours to obtain ceria-supported nickel oxide (NiO / CeO 2 );

[0038] (2) Take 1g NiO / CeO 2 , 0.5g of glucose and 2.0g of urea, ball milled to make them evenly mixed;

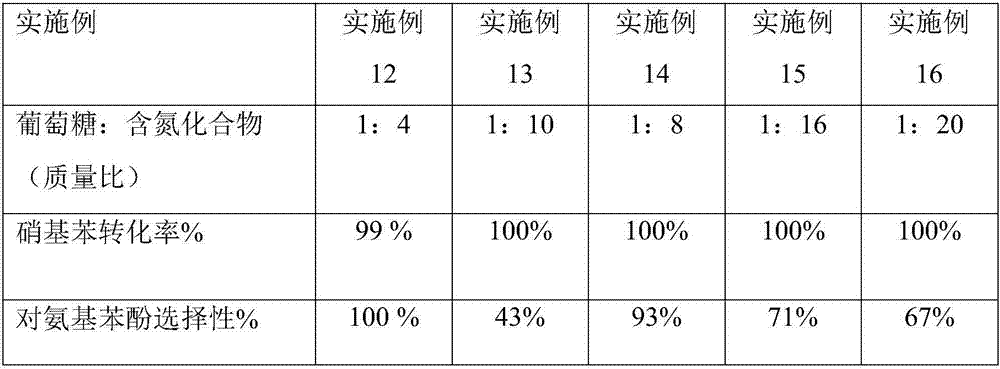

[0039] (3) Then calcined at 600°C for 6 hours in a nitrogen atmosphere to obtain a black powder catalyst (CN / Ni / CeO 2 ). It is used to catalyze the hydrogenation of nitrobenzene to synthesize p-aminophenol, and the conversion rate of nitrobenzene is 99%. The p-aminophenol selectivity is 100%.

Embodiment 13

[0041] The method is the same as in Example 12, except that the amount of glucose is 0.2 g, and the obtained catalyst catalyzes the hydrogenation of nitrobenzene to synthesize p-aminophenol, wherein the conversion rate of nitrobenzene is 100%, and the selectivity of p-aminophenol is 43%. .

[0042] Embodiment 13-16 investigated the impact of the catalyst obtained in the mass ratio of different glucose and nitrogen-containing compounds in step (2) to catalyze the hydrogenation of nitrobenzene to synthesize p-aminophenol, see Table 4, and all the other are the same as in Example 12, wherein the nitrogen-containing compounds Any one of urea, melamine, dicyandiamide, pyrrole, polypyrrole, urea-formaldehyde resin and polyvinylpyrrolidone:

[0043] Table 4

[0044]

[0045] Embodiment 17, 18 has investigated the impact of the catalyst catalyzed hydrogenation of nitrobenzene to synthesize p-aminophenol in different nitrogen atmospheres in the step (3) by the treatment temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com