Stereoscopic light-cured rapid-formed high-temperature-resistant photosensitive resin and preparation method thereof

A technology of stereolithography and photosensitive resin, which is applied in the field of high temperature resistant photosensitive resin and its preparation, can solve the problems of poor quality stability, single category, rare resin, etc., and achieve the best market effect, economic value and dimensional stability Good, good surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-temperature-resistant photosensitive resin for stereolithography rapid prototyping and a preparation method thereof. The preparation method is to weigh each component according to the mass ratio and add them to a stirrer respectively, and mix and stir the materials in the stirrer while heating, Keep the temperature of the material at 50° C., mix and stir for 20 minutes, and obtain a high temperature resistant photosensitive resin after mixing evenly.

[0037] The mass ratio of each raw material is: 65g bisphenol F type cyanate ester resin, 45g aromatic urethane acrylate, 30g cyclohexyl methacrylate, benzoin dimethyl ether 1.8g, 0.5g dibutyltin dilaurate, 0.5g Polyoxypropylene polyoxyethylene glyceryl ether, 0.3g silicone modified polysiloxane.

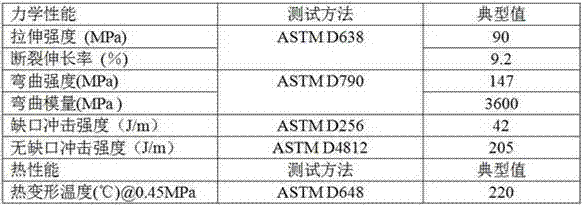

[0038] The prepared high-temperature-resistant photosensitive resin is printed with a test sample by Formlabs' From 2 model to obtain a cured product, and the cured product is subjected to a post-processing process to obt...

Embodiment 2

[0044] A high-temperature-resistant photosensitive resin for stereolithography rapid prototyping and a preparation method thereof. The preparation method is to weigh each component according to the mass ratio and add them to a stirrer respectively, and mix and stir the materials in the stirrer while heating, Keep the temperature of the material at 65° C., mix and stir for 30 minutes, and obtain a high-temperature-resistant photosensitive resin after mixing evenly.

[0045] The mass ratio of each raw material is: 45g dicyclopentadiene cyanate resin, 35g alicyclic urethane acrylate, 20g cyclotrimethylolpropane methylal acrylate, 1.2g benzoin dimethyl ether, 0.5g dilaurel Dibutyltin dibutyltin, 0.3g polyoxypropylene polyoxyethylene glyceryl ether, 0.2g organosilicon-modified polysiloxane.

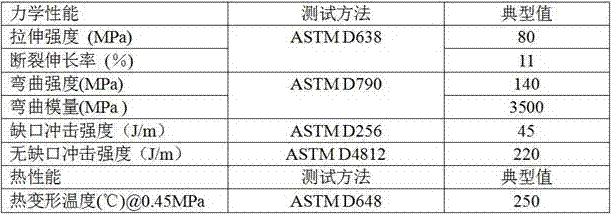

[0046] The prepared high-temperature-resistant photosensitive resin is printed with a test sample by Formlabs' From 2 model to obtain a cured product, and the cured product is subjected to a p...

Embodiment 3

[0052] A high-temperature-resistant photosensitive resin for stereolithography rapid prototyping and a preparation method thereof. The preparation method is to weigh each component according to the mass ratio and add them to a stirrer respectively, and mix and stir the materials in the stirrer while heating, Keep the temperature of the material at 75° C., mix and stir for 45 minutes, and obtain a high temperature resistant photosensitive resin after mixing evenly.

[0053] The mass ratio of each raw material is: 1000g bisphenol A cyanate resin, 790g polyester acrylate, 500g isobornyl acrylate, 11.3g benzophenone, 15.2g dibutyltin dilaurate, 6.4g polyoxygen Propylene polyoxyethylene glyceryl ether, 5.3g polymethylphenylsiloxane, 20g chromate dye additive, 7.9g amino acid surfactant.

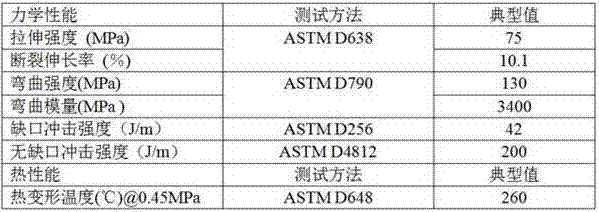

[0054] The prepared high-temperature-resistant photosensitive resin is printed with a test sample by Formlabs' From 2 model to obtain a cured product, and the cured product is subjected to a post-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com