A high-efficiency and energy-saving oxidation method for waste cemented carbide

A cemented carbide, high-efficiency and energy-saving technology, applied in the field of metal materials, can solve the problems of high temperature, difficult crushing, long time consumption, etc., to achieve the effect of good quality, short process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

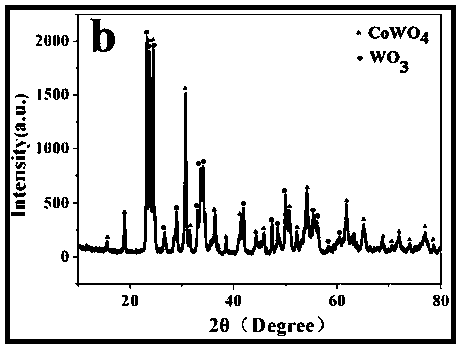

Image

Examples

Embodiment 1

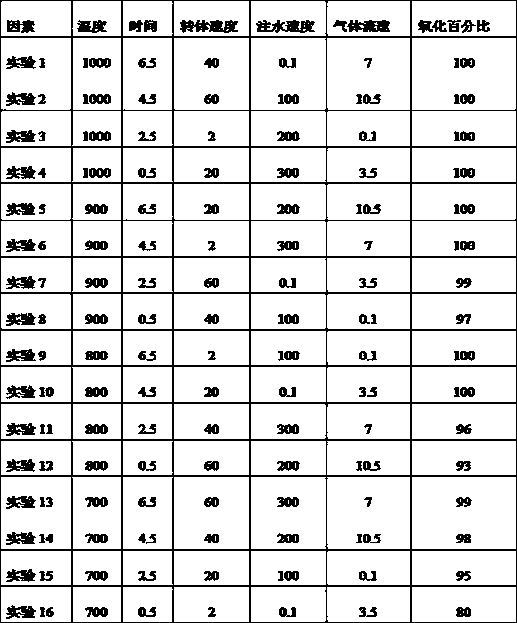

[0016] The tungsten-cobalt YG8 cemented carbide was subjected to 80 g.L -1 Sodium hydroxide, 30 g.L -1 Sodium carbonate and 60 g.L -1 After washing and drying the trisodium phosphate aqueous solution, take 5000g and place it in the calciner. 3 / h, 3.5m 3 / h, 7.0m 3 / h, 10.5m 3 / h, the speed of the furnace body is 2 r / min, 20 r / min, 40r / min, 60r / min, and the water injection speed is 0.1ml / min, 100ml / min, 200 ml / min, 300 ml / min calcination at 700°C, 800°C, 900°C, 1000°C, and calcination times of 0.5h, 2.5h, 4.5h, and 6.5h, respectively.

[0017] The oxidation percentage of cemented carbide obtained after medium and high temperature treatment is shown in Table 1:

[0018] Table 1 Oxidation effects of different oxidation processes

[0019]

[0020] From the data in the above table, it can be concluded that when the treatment temperature is lower than 700 °C, the waste cemented carbide cannot be completely oxidized, and when the treatment temperature is higher than 1000 °...

Embodiment 2

[0023] The tungsten-cobalt YG12 cemented carbide was subjected to 80 g.L -1 Sodium hydroxide, 30 g.L -1 Sodium carbonate and 60 g.L -1 After washing and drying the trisodium phosphate aqueous solution, take 5000g and place it in the calcination chamber, with a gas flow rate of 3.5m 3 / h, the rotational speed of the furnace body is 60 r / min, and the water injection speed is 200ml / min. Oxidize and calcinate at 1050 ˚C for 1h, and the cemented carbide is completely oxidized.

Embodiment 3

[0025] The tungsten-cobalt YG18 cemented carbide was subjected to 80 g.L -1 Sodium hydroxide, 30 g.L -1 Sodium carbonate and 60 g.L -1 After washing and drying the trisodium phosphate aqueous solution, take 5000g and place it in the calcination chamber, with a gas flow rate of 10.5m 3 / h, the rotational speed of the furnace body is 40 r / min, and the water injection speed is 300ml / min. The cemented carbide is completely oxidized at a temperature of 900 °C for 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com