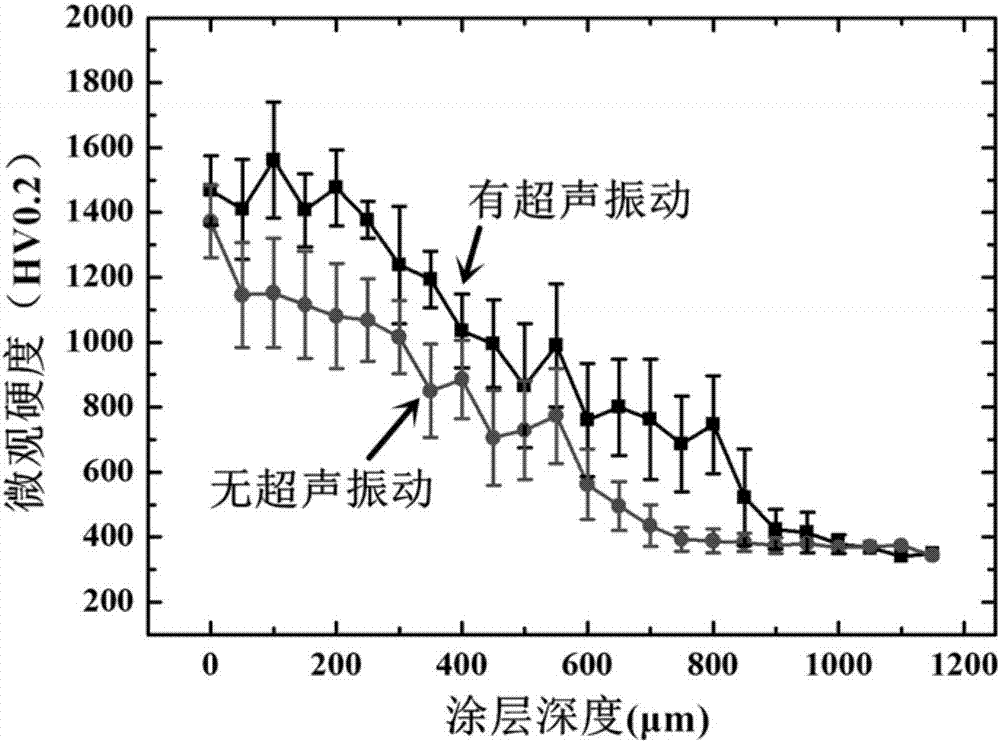

Method and device for preparing fine-grain Ti3Al/TiN gradient coatings on titanium and titanium alloy surfaces

A gradient coating and titanium alloy technology, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems of coarse grain of nitride layer, large surface roughness, complicated preparation process, etc. Achieve the effects of small friction coefficient and wear scar depth, uniform transition of coating structure and good coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

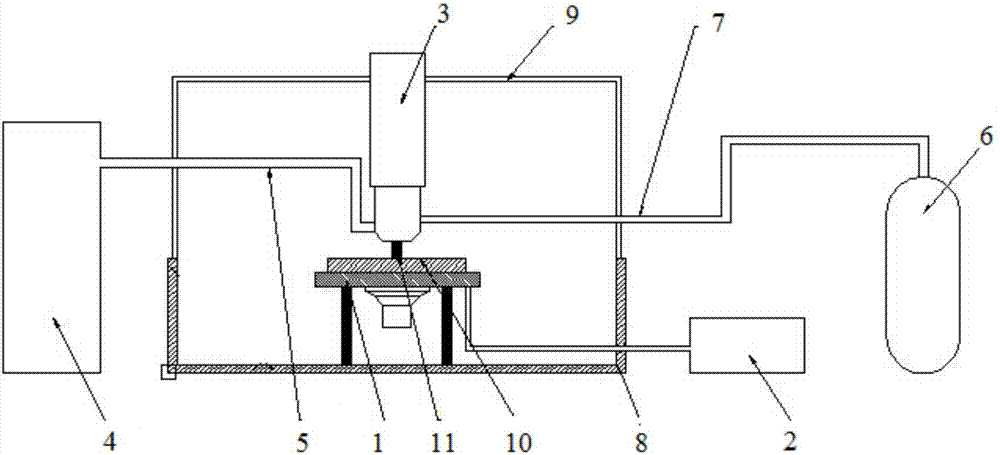

Embodiment 1

[0039] First, provide a titanium alloy substrate (Ti-6Al-4V) with a thickness of 6mm as the workpiece substrate 10, perform ultrasonic cleaning on its surface, and perform surface roughening treatment. The roughening treatment uses a surface sanding device with an air injection pressure of 0.2 Mpa, the roughened particles used are Al 2 o 3 Particles, the nozzle is 5cm away from the sample surface. use as figure 1 In the shown device, firstly, the workpiece substrate 10 is fixed on the ultrasonic vibration platform 1, and the ultrasonic vibration platform 1 is placed in the sealed box 8 by opening the soft silica gel plate shell 9, and the vacuum is pumped, and the inside of the sealed box 8 is vacuumized. After the air is completely exhausted, a vacuum environment is formed, and then high-purity nitrogen is continuously introduced into the sealed box 8 through the nitrogen delivery pipeline 7, and the inflation time is > 5 minutes, so that the sealed box 8 is filled with nit...

Embodiment 2

[0045] Firstly, a titanium alloy substrate (Ti-6Al-4V) with a thickness of 6mm is provided as the workpiece substrate 10, and its surface is chemically ultrasonically cleaned, and the surface is roughened. A surface sanding device is used for the roughening treatment, and the air jet pressure is 0.2Mpa, the roughened particles used are Al 2 o 3 Particles, the nozzle is 5cm away from the sample surface. use as figure 1 In the shown device, the workpiece substrate 10 is fixed on the ultrasonic vibration platform 1, the ultrasonic vibration platform 1 is placed in the sealed box 8, and vacuumized. After the air in the sealed box 8 is completely discharged, a vacuum environment is formed, and then Continuously feed high-purity nitrogen into the sealed box 8 through the nitrogen delivery pipeline 7, and fill the sealed box 8 with nitrogen for more than 5 minutes; then turn on the ultrasonic generator 2, and wait until the power of the ultrasonic generator 2 reaches 100W , turn o...

Embodiment 3

[0047] Firstly, a titanium alloy substrate (Ti-6Al-4V) with a thickness of 6mm is provided as the workpiece substrate 10, and its surface is chemically ultrasonically cleaned, and the surface is roughened. A surface sanding device is used for the roughening treatment, and the air jet pressure is 0.2Mpa, the roughened particles used are Al 2 o 3 Particles, the nozzle is 5cm away from the sample surface. use as figure 1 In the shown device, the workpiece substrate 10 is fixed on the ultrasonic vibration platform 1, the ultrasonic vibration platform 1 is placed in the sealed box 8, and vacuumized. After the air in the sealed box 8 is completely discharged, a vacuum environment is formed, and then Continuously feed high-purity nitrogen into the sealed box 8 through the nitrogen delivery pipeline 7, and fill the sealed box 8 with nitrogen for more than 5 minutes; then turn on the ultrasonic generator 2, and wait until the power of the ultrasonic generator 2 reaches 100W , turn o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com