Application of sodium dichloroacetate in preparation of low protein feed for pigs

A sodium dichloroacetate, low-protein technology, applied in the field of livestock and poultry breeding feed, can solve the problem that low-protein feed has not yet become a general technology for pig production, and achieves a simple and reliable production method, reduced urinary nitrogen discharge, and common feed materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

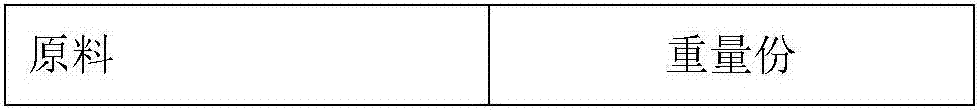

[0036] A low-protein feed for pigs based on amino acid metabolism thrift, comprising:

[0037]

[0038] The pig premix, calculated per ton, includes: 4.67 kg of 1% calcium iodate, 20.00 kg of 1% sodium selenite, 26.70 kg of ferrous sulfate monohydrate, 22.96 kg of zinc sulfate monohydrate, Copper sulfate 5.34 kg, manganese sulfate monohydrate 12.02 kg, vitamin A 1.07 kg, 98% vitamin B1 0.11 kg, 96% vitamin B2 0.43 kg, 98% vitamin B6 0.27 kg, 1% vitamin B12 0.05 kg, vitamin D3 0.21 kg , 50% vitamin E 2.00 kg, 50% choline chloride 66.8 kg, 2% biotin 0.35 kg, 99% niacin 1.20 kg, 97% folic acid 0.05 kg, 98% pantothenic acid 1.01 kg, 25% vitamin K3 2.67 kg, Antioxidant (ethoxyquinoline) 2.67 kilograms, all the other are zeolite powder.

[0039] (2) Processing and preparation method

[0040] (a) Grinding corn, soybean meal, wheat bran, fish meal, and fat powder to a mesh size of 90 mesh;

[0041] (b) First, divide the raw materials into three categories. The first category is ...

Embodiment 2

[0045] Application of a pig low-protein feed based on amino acid metabolism thrift in pig production:

[0046] First carry out the nitrogen balance test. With 16 of 20kg Du × long × big three-way crossbreed pigs, be divided into 2 groups (test group and control group), test group is fed with the feed prepared by the embodiment of the present invention 1, and matched group is fed with feed containing 18% crude protein regular feed. The test period is 2 weeks, the first week is the pre-test period, and the second week is the sample collection period. The feed intake, feces and urine are collected, the protein content is analyzed, and the nitrogen balance is calculated.

[0047] At the same time, a feeding experiment was carried out. 40 of Du × long × large three-way hybrid pigs of 15kg are divided into 2 groups (test group and control group), the test group is fed with the feed prepared by the embodiment of the present invention 1, and the control group is fed with the feedstu...

Embodiment 3

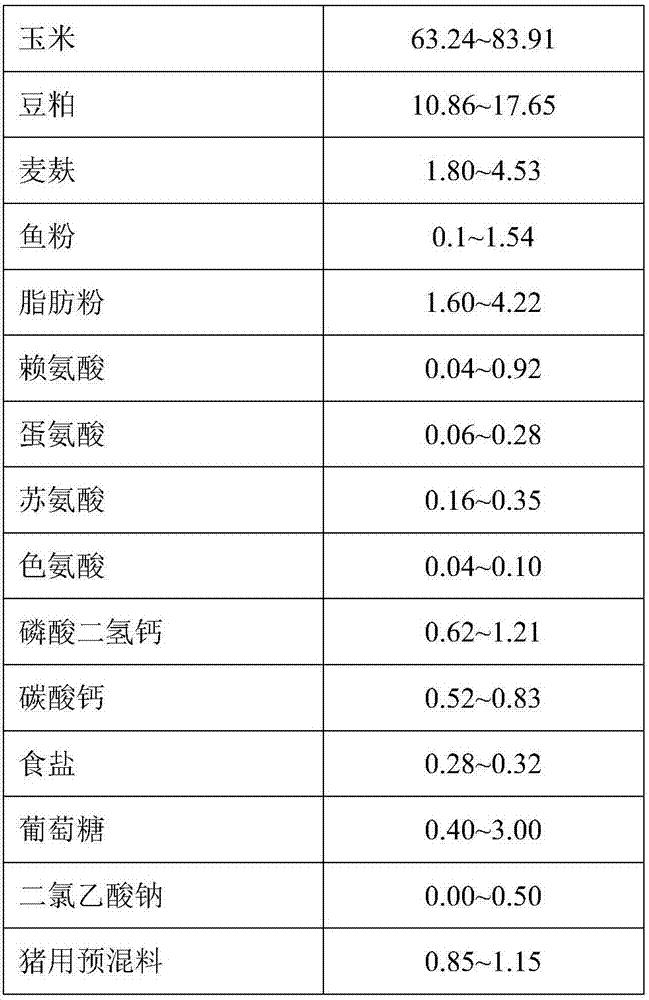

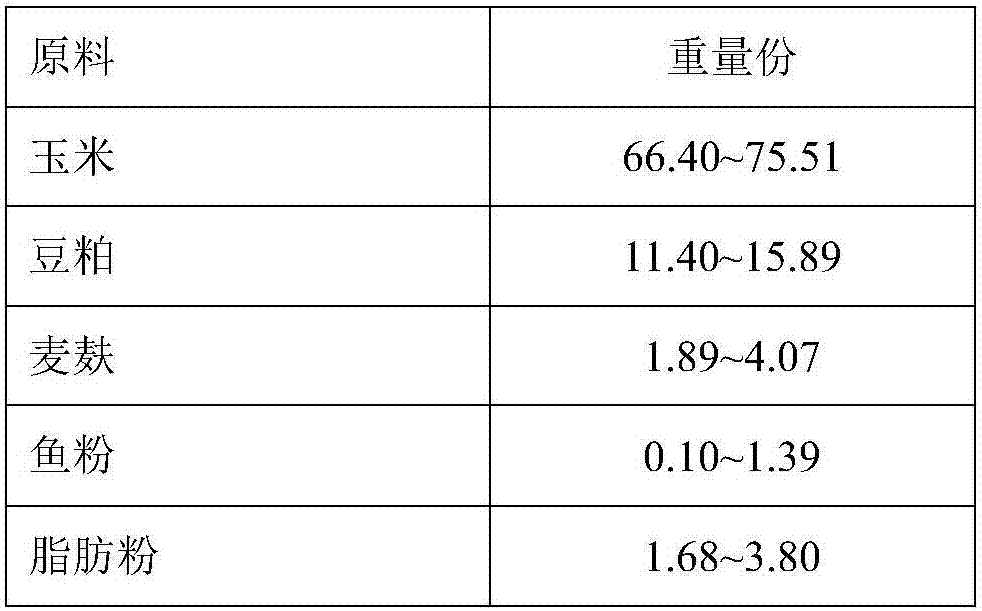

[0055] A low-protein feed for pigs based on amino acid metabolism thrift, comprising:

[0056]

[0057] The formula of described pig premix is the same as embodiment 1

[0058] The preparation steps are the same as in Example 1, and the crude protein content of the finally prepared feed is 12.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com