Catalyst for room-temperature catalytic oxidation of formaldehyde pollutants and preparation method and application thereof

A catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high precious metal content, complex catalyst preparation, and poor formaldehyde purification effect. and other problems, to achieve the effect of repeatable preparation process, high formaldehyde purification effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

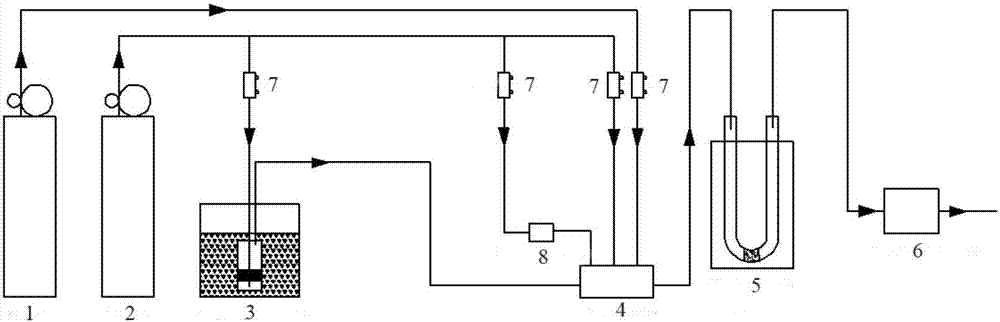

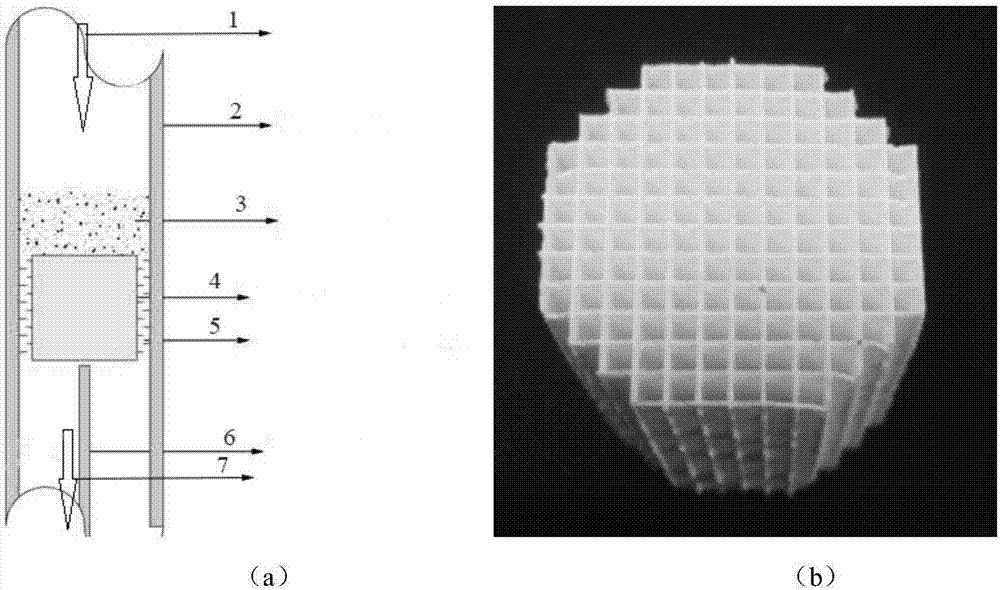

[0043] Preparation and testing of honeycomb catalyst: Mix the ground catalyst powder with water at a solid-to-liquid ratio of 30% to prepare a slurry; then coat it on a honeycomb cordierite carrier and dry and roast it After that, the honeycomb catalyst sample was prepared; the figure 1 The U-shaped reaction tube in the device is replaced by a straight tube, and the catalyst of 1in*1in (inch, about 25.4mm) is loaded into the straight tube with an inner diameter of 30mm. The loading diagram of the catalyst is as follows figure 2 As shown, the straight tube was placed in a water bath with a constant temperature of 25°C. A certain concentration of formaldehyde is passed into the inlet of the straight pipe, and the outlet gas is analyzed online by a special formaldehyde analyzer.

[0044] Catalyst activity evaluation experimental conditions are as follows: under room temperature conditions, volume composition (volume ratio): oxygen: 20%, nitrogen: 80%, relative humidity RH is 0...

Embodiment 1

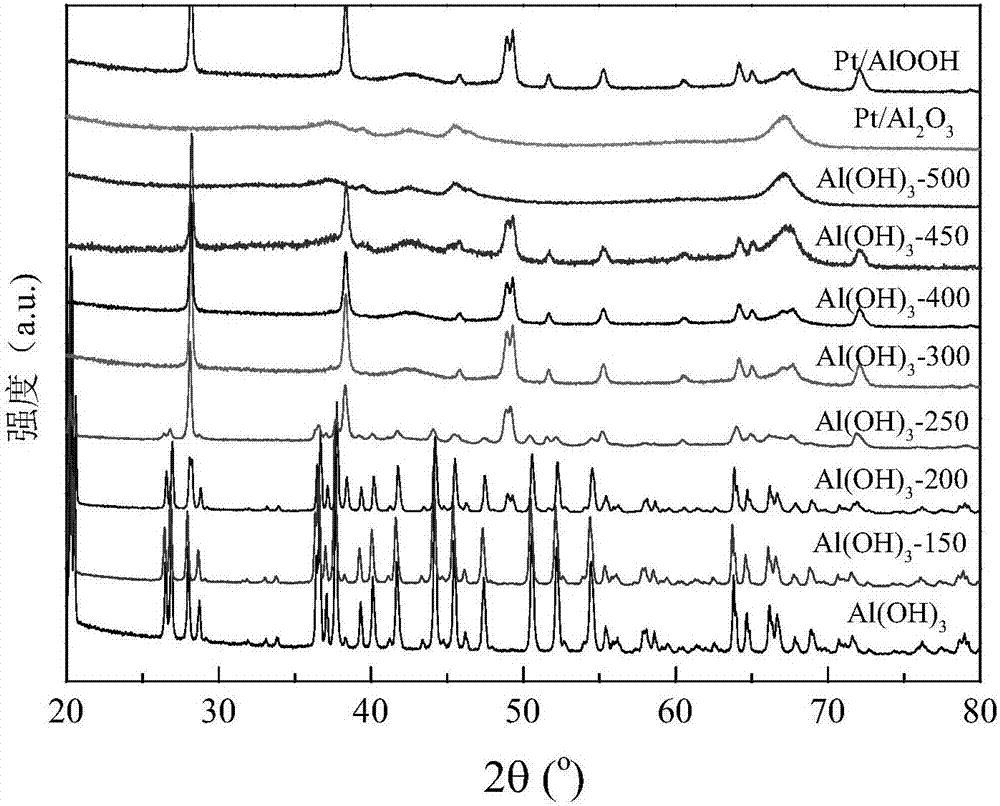

[0045] Embodiment 1: the preparation method of aluminum oxide monohydrate (AlOOH)

[0046] First make your own or buy commercial Al(OH) 3 . Laboratory-made Al(OH) 3 There are two main methods: the reaction of soluble aluminum salts with ammonia water, and the reaction of sodium metaaluminate with excess carbon dioxide.

[0047] Preparation of Al(OH) by Reaction of Soluble Aluminum Salt and Ammonia 3 The steps are: measure 10ml of AlCl with a concentration of 1mol / L 3 Solution, under the condition of stirring, dilute ammonia water with a concentration of 0.5mol / L was added dropwise to it, and the dropping time was controlled at more than 2h until no precipitation appeared, and then the obtained precipitation was washed with deionized water and ethanol respectively. Centrifuge and wash 3 times, then dry it to get Al(OH) 3 .

[0048] Preparation of Al(OH) by Reacting Sodium Metaaluminate with Excess Carbon Dioxide 3 The steps are: weigh 5.0g of sodium metaaluminate solid, ...

Embodiment 2

[0050] Embodiment 2: Preparation of 1Pt(N) / AlOOH catalyst and its activity test

[0051] Use a pipette to measure 2ml of Pt(NO 3 ) 2 (10g Pt / L, the same below) is placed in a 50ml beaker; add a stirring rotor to it, put it on the stirrer and stir, add an appropriate amount of deionized water, and add 2.0g of AlOOH prepared by roasting at 300°C in Example 1 to the beaker Carrier; stir at room temperature for 12 hours to distribute the active components evenly; after stirring, heat the two samples to 70°C and continue stirring until viscous (paste); put the samples in a drying oven for drying (110°C, 12h); after drying, the sample was taken out, and after cooling to room temperature, it was ground into a powder; the sample was placed in a crucible and baked in a muffle furnace (300°C, 3h); After the burning is completed, after the temperature in the muffle furnace is cooled to room temperature, the sample is pressed into tablets and sieved into 40-60 meshes for reduction.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com