Thin type thermal battery isolation sheet and preparation method therefor

A technology of separators and thermal batteries, applied in the direction of delayed action cells, etc., can solve the problems of electrolyte electrical noise, battery short circuit, poor power performance, etc., to improve high-power discharge performance, improve high-power discharge capacity, and improve the degree of automated production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

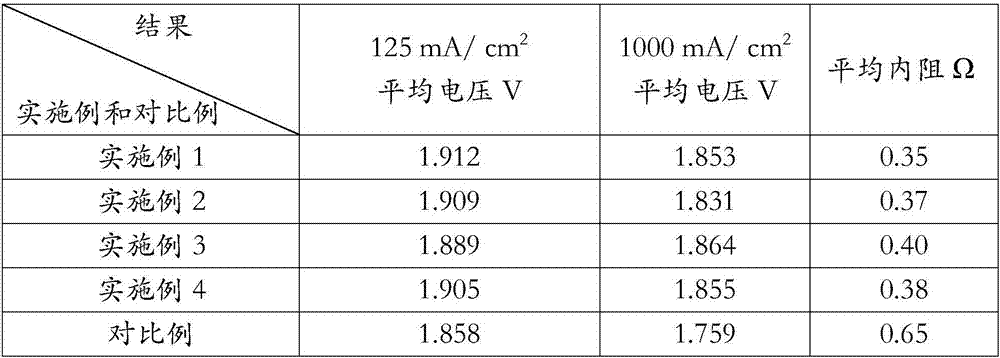

Examples

Embodiment 1

[0034] A preparation method of a thin thermal battery separator, comprising the following steps:

[0035] (1) Preparation of electrolyte salt saturated solution: in natural environment, mix electrolyte salt and dispersant, stir at 100°C, stirring speed is 200r / min, stirring time is 30min, obtain electrolyte salt saturated solution; wherein, dispersing The solvent is 50% absolute ethanol; the electrolyte salt is a mixture of KCl and LiCl, the mass percentage of KCl is 40%, the mass percentage of LiCl is 60%; the mass percentage of the electrolyte salt is 60%, and the mass percentage of the dispersant The content is 40%.

[0036] (2) In the natural environment, use glass fiber as the supporting matrix, immerse it in the electrolyte salt saturated solution, keep the temperature of the solution at 100°C for 30s, and then take it out to obtain the separator; the thickness of the glass fiber matrix is 100 μm, and the pore size 1.0 μm;

[0037] (3) In an environment with a humidi...

Embodiment 2

[0040] A preparation method of a thin thermal battery separator, comprising the following steps:

[0041] (1) Preparation of electrolyte salt saturated solution: in natural environment, mix electrolyte salt and dispersant, stir at 200°C, stirring speed is 600r / min, and stirring time is 1h, to obtain electrolyte salt saturated solution; among them, dispersing The agent is distilled water; the electrolyte salt is a mixture of KCl and LiCl, the mass percentage of KCl is 45%, and the mass percentage of LiCl is 55%; wherein, the mass percentage of the electrolyte salt is 15%, and the mass percentage of the dispersant is 85%;

[0042] (2) In the natural environment, use glass fiber as the supporting matrix, immerse it in the saturated solution of electrolyte salt, keep the temperature of the solution at 200 °C for 5 seconds, and then take it out to obtain the separator; the thickness of the glass fiber matrix is 200 μm, and the pore size 2.0 μm;

[0043](3) In an environment wit...

Embodiment 3

[0046] A preparation method of a thin thermal battery separator, comprising the following steps:

[0047] (1) Preparation of electrolyte salt saturated solution: in natural environment, mix electrolyte salt and dispersant, stir at 150°C, stirring speed is 300r / min, stirring time is 6h, obtain electrolyte salt saturated solution; wherein, dispersing Agent is distilled water; Electrolyte salt is the mixture of LiCl, LiBr and KBr, the mass percentage of LiCl is 10%, the mass percentage of LiBr is 40%, the mass percentage of KBr is 50%; Wherein, the mass percentage of electrolyte salt is 80% %, the mass percentage of dispersant is 20%;

[0048] (2) In the natural environment, use the metal oxide film as the supporting substrate, immerse it in the electrolyte salt saturated solution, keep the temperature of the solution at 150 ° C for 1 min, and then take it out to obtain the separator; the thickness of the metal oxide film is 110 μm , the pore size is 0.8 μm;

[0049] (3) In an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com