A metatitanic acid-coated alumina core-shell abrasive grain polishing liquid composition and preparation method thereof

A technology of polishing liquid composition and core-shell abrasive grains, which is applied in the fields of polishing compositions containing abrasives, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve the problem of many scratches on the surface of sapphire substrates and unsatisfactory polishing results , high surface roughness, etc., to achieve the effect of improving polishing scratches and surface damage, reducing surface roughness, and increasing polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

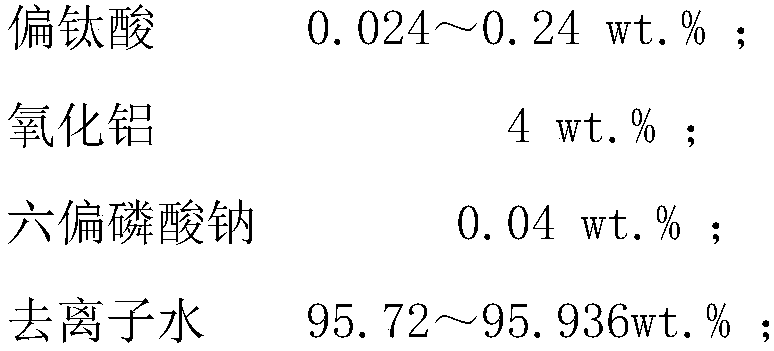

Embodiment 1

[0022] A method for preparing a metatitanic acid-coated alumina core-shell abrasive grain polishing fluid composition, the steps are as follows:

[0023] (1). Disperse 100g of alumina into 900g of deionized water, then add 1g of dispersant sodium hexametaphosphate, stir evenly, carry out ultrasonic dispersion, and finally carry out ball mill dispersion to obtain a mass fraction of 5% alumina aluminum paste;

[0024] (2). Under stirring at 100°C, 25 mL of titanium sulfate with a molar concentration of 0.25 mol / L and a sodium hydroxide solution with a mass fraction of 5% are simultaneously added dropwise to the mixed slurry obtained in step (1), and the control The rate of addition of titanium sulfate and sodium hydroxide, the rate of addition is the same as the evaporation rate of the solution, so that the liquid level of the reaction solution remains constant, and the pH of the reaction solution is 10; after the addition of titanium sulfate, stop adding hydrogen Sodium oxide,...

Embodiment 2

[0033] A method for preparing a metatitanic acid-coated alumina core-shell abrasive grain polishing fluid composition, the steps are as follows:

[0034] (1). Disperse 100g of alumina into 900g of deionized water, then add 1g of dispersant sodium hexametaphosphate, stir evenly, carry out ultrasonic dispersion, and finally carry out ball mill dispersion to obtain a mass fraction of 5% alumina aluminum paste,

[0035] (2). Under stirring at 100°C, 50 mL of titanium sulfate with a molar concentration of 0.25 mol / L and a sodium hydroxide solution with a mass fraction of 5% are simultaneously added dropwise to the mixed slurry obtained in step (1), and the control The rate of addition of titanium sulfate and sodium hydroxide, the rate of addition is the same as the evaporation rate of the solution, so that the liquid level of the reaction solution remains constant, and the pH of the reaction solution is 10; after the addition of titanium sulfate, stop adding hydrogen Sodium oxide,...

Embodiment 3

[0044] A method for preparing a metatitanic acid-coated alumina core-shell abrasive grain polishing fluid composition, the steps are as follows:

[0045] (1). Disperse 100g of alumina into 900g of deionized water, then add 1g of dispersant sodium hexametaphosphate, stir evenly, carry out ultrasonic dispersion, and finally carry out ball mill dispersion to obtain a mass fraction of 5% alumina aluminum paste;

[0046] (2). Under stirring at 100°C, the molar concentration of 100mL is that the titanium sulfate of 0.25mol / L and the sodium hydroxide solution that the mass fraction is 5% are added dropwise in the mixed slurry of step (1) gained simultaneously, control The rate of addition of titanium sulfate and sodium hydroxide, the rate of addition is the same as the evaporation rate of the solution, so that the liquid level of the reaction solution remains constant, and the pH of the reaction solution is 10; after the addition of titanium sulfate, stop adding hydrogen Sodium oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com