Multi-purpose advanced strong binder

An adhesive, multi-purpose technology, applied in the directions of polymer adhesive additives, adhesives, non-polymer adhesive additives, etc., can solve problems such as wall tiles falling off, achieve not easy cracking, ensure stability, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

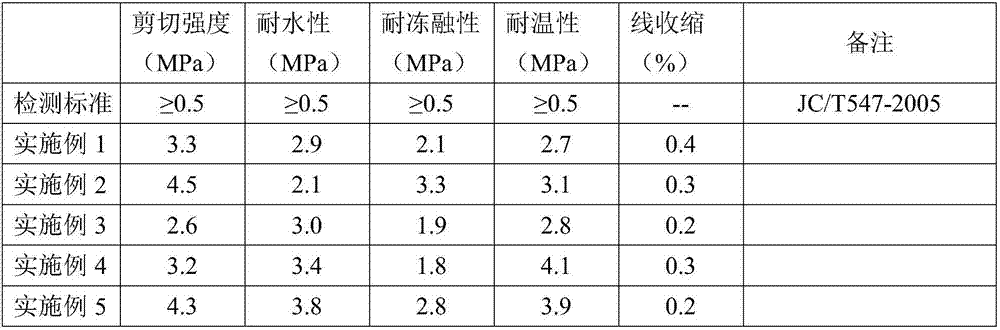

Examples

Embodiment 1

[0050] Embodiment 1, select 35 parts by weight of styrene-acrylic emulsion, 35 parts by weight of silicon-acrylic emulsion are mixed to form aqueous polymer resin, 15 parts by weight of emulsified terpene phenolic resin, 5 parts by weight of heavy calcium carbonate (the particle size range is less than 45 microns), 5 parts by weight of superfine talcum powder (the particle size range is less than 45 microns), 0.3 parts by weight of polyacrylate thickener, 0.3 parts by weight of fatty alcohol defoamer, 0.2 parts by weight of methacrylate, magnesium aluminum silicate thixotropic agent 0.4 parts by weight, 0.7 parts by weight of diphenylamine in emulsion, 10100.1 parts by weight of antioxidant, 0.5 parts by weight of sodium pentachlorophenate, and 2.5 parts by weight of deionized water. Stir well to make a binder.

Embodiment 2

[0051] Embodiment 2, select 70 parts by weight of styrene-acrylic emulsion, 15 parts by weight of emulsified rosin ester, 5 parts by weight of light calcium carbonate (the particle size range is less than 45 microns), 5 parts by weight of superfine talcum powder (the particle size range is less than 45 microns) , 0.3 parts by weight of acrylate copolymer thickener, 0.3 parts by weight of fatty alcohol defoamer, 0.2 parts by weight of fatty alcohol polyoxyethylene ether, 0.4 parts by weight of organic bentonite thixotropic agent, 0.3 parts by weight of diphenylamine in emulsion, anti 0.5 parts by weight of oxygen agent 1076, 0.5 parts by weight of sodium 2,4,5-trichlorophenolate, and 2.5 parts by weight of deionized water. Mix the materials in proportion and put them into a high-speed dispersing kettle and stir them evenly to make a binder.

Embodiment 3

[0052] Embodiment 3, get 75 parts by weight of acrylic acid emulsion, 15 parts by weight of emulsified petroleum resin, 8 parts by weight of quartz powder (the particle size range is less than 45 microns), 0.3 parts by weight of hydroxyethyl cellulose ether thickener, fatty alcohol defoamer 0.3 parts by weight, 0.2 parts by weight of maleic anhydride copolymer, 0.4 parts by weight of organic bentonite thixotropic agent, 0.5 parts by weight of dihydroquinoline, 0.5 parts by weight of antioxidant 1076, 0.5 parts by weight of sodium 2,4,5-trichlorophenolate parts, 2.5 parts by weight of deionized water. Mix the above materials, put them into a high-speed dispersing tank according to the proportion, stir well, and make a binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com