Preparation method of nano-fluorapatite glass ceramic

A fluoroapatite and glass ceramic technology, which is applied in the field of preparation of nano-fluoroapatite glass ceramics, can solve the problems of long production cycle, high equipment requirements, long glass nucleation and crystallization heat treatment time, etc., and achieves easy crystallization. Chemical and processability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of nano fluorapatite glass ceramics, comprising the following steps:

[0023] (1) Preparation of fluoroapatite powder: use the chemical precipitation method to prepare fluoroapatite powder with a particle size of about 30nm, then dry it in a vacuum drying oven at a temperature of 60°C, and finally put the powder into a corundum ball mill jar Ball mill for 1 hour, then pass through a 200-mesh sieve;

[0024] (2) Preparation of fluorine phlogopite powder: Pour high-temperature molten raw materials into water at room temperature for quenching, then dry them in a vacuum oven at 60°C, then put the raw materials into a corundum ball mill jar for ball milling for 1 hour, and pass through 200 mesh ;

[0025] (3) Mixing: the proportioning ratio is 70% of fluorphlogopite powder and 30% of fluoroapatite powder in parts by weight, put into a ball mill for mixing, and the mixing time is 5h;

[0026] (4) Compression molding: press the uniformly mixed powder int...

Embodiment 2

[0029] A preparation method of nano fluorapatite glass ceramics, comprising the following steps:

[0030] (1) Preparation of fluoroapatite powder: use the chemical precipitation method to prepare fluoroapatite powder with a particle size of about 60nm, then dry it in a vacuum drying oven at a temperature of 80°C, and finally put the powder into a corundum ball mill jar Medium ball mill for 4 hours, then pass through a 200-mesh sieve;

[0031] (2) Preparation of fluorphlogopite powder: Pour high-temperature molten raw materials into water at room temperature for quenching, then dry them in a vacuum drying oven at a temperature of 80°C, then put the raw materials into a corundum ball mill jar for ball milling for h, and pass through 200 mesh screen;

[0032] (3) Mixing: select the proportioning by weight to be 70% of fluorphlogopite powder and 30% of fluoroapatite powder, put them into a ball mill for mixing, and the mixing time is 3 hours;

[0033] (4) Compression molding: pr...

Embodiment 3

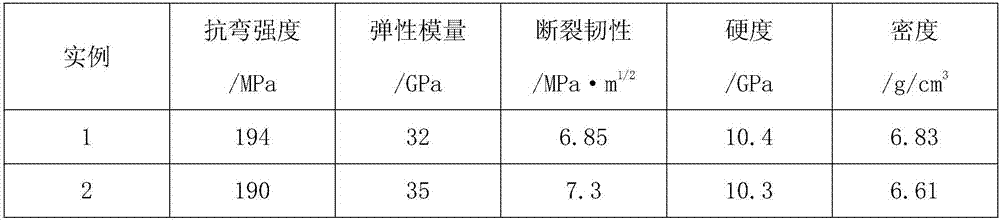

[0035] Performance test of the nanometer fluoroapatite glass-ceramic obtained in embodiment 3

[0036] Carry out mechanical property test to the glass-ceramic of above gained:

[0037] The relative density of the sintered compact is measured using the Archimedes principle, the flexural strength and elastic modulus are measured on a universal testing machine, the fracture toughness of the material is measured on a HD9-45 hardness tester, and the load is 100N. The loading time is 15s, and the Vickers hardness of the material is calculated by the following formula: H=1.8544P / d 2 , where H is the Vickers hardness (HV), P is the load of the indenter (N), and d is the average value of the indentation diagonal (um); the fracture toughness of the material is measured by the indentation method, and at 500 times XJP- Measure the diagonal length of the indentation and the length of the indentation crack under a 200-type metallographic microscope, and use the following formula to calcula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com