Gemini surfactant, and preparation method and applications thereof

A Gemini surface and active agent technology, applied in the direction of sulfonate preparation, chemical instruments and methods, drilling compositions, etc., can solve the problems of loss and foam discharge agent reduction, and achieve high liquid carrying rate and low surface tension , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

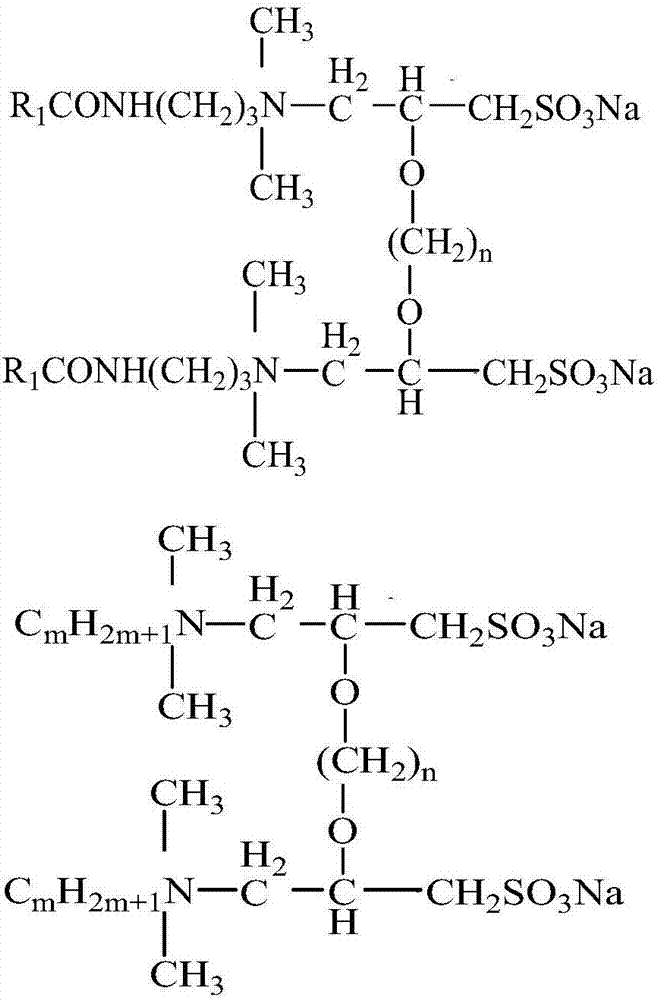

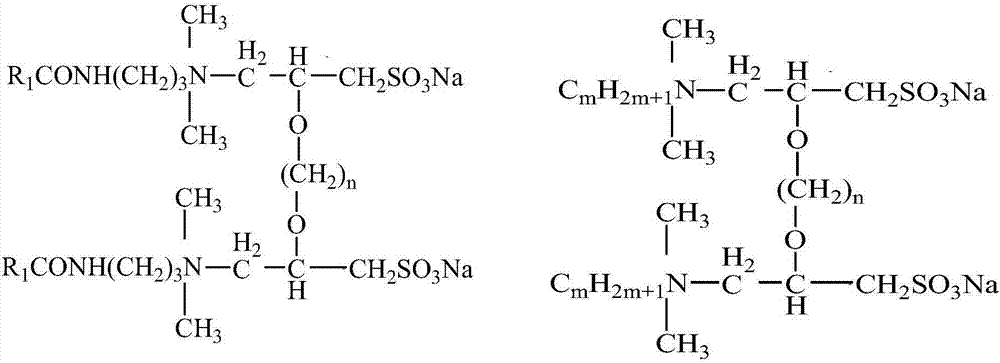

[0025] The present invention provides a kind of gemini surfactant and its preparation method and application, a kind of preparation method of gemini surfactant, comprises the following steps successively:

[0026] (1) Preparation of fatty hydroxypropyl sulfobetaine: Mix 15-20 parts of 3-chloro-2-hydroxypropanesulfonate sodium and 100 parts of isopropanol aqueous solution into a three-necked flask, and heat to dissolve; then add 25-50 parts of aliphatic tertiary amine, react at a temperature of 70-90°C for 4-6 hours, and keep the pH value of the system at 9-10; after the reaction, first evaporate the solvent to dryness, add methanol to filter to remove inorganic salts, and distill the filtrate After the solvent is removed, the crude product is obtained, and the mixed solvent of ethyl acetate and acetone with a mass fraction ratio of 7:3 is used for repeated recrystallization several times, and the solid product obtained is fatty hydroxypropyl sulfobetaine; wherein isopropyl The...

Embodiment 1

[0043] The first step: in a reactor with a reflux condenser, mix 18.43 parts of 3-chloro-2-hydroxypropanesulfonate sodium and 100 parts of isopropanol aqueous solution (the ratio of isopropanol to water is 3:1) Added to the three-necked flask, and heated to dissolve. Then add 43.50 parts of oleic acid amidopropyl tertiary amine, control the temperature of 70° C., react for 4 hours, and keep the pH value of the system at 9. After the reaction, first evaporate the solvent to dryness, add methanol and filter to remove the inorganic salt, and distill the filtrate to remove the solvent to obtain the crude product. Then use the mixed solution of ethyl acetate and acetone with a mass fraction ratio of 7:3 to repeatedly recrystallize several times, and the solid product is oleic acid amide hydroxypropyl sulfobetaine.

[0044]Step 2: Add 109.95 parts of oleamide hydroxypropyl sulfobetaine and 70 parts of ethylene glycol dimethyl ether into the reaction bottle, mix well, add 8 parts of...

Embodiment 2

[0046] The first step: In a reactor with a reflux condenser, mix 19.66 parts of 3-chloro-2-hydroxypropanesulfonate sodium and 100 parts of isopropanol aqueous solution (the ratio of isopropanol to water is 3:1) Added to the three-necked flask, and heated to dissolve. Then add 47.12 parts of cocamidopropyl tertiary amine, control it at 80°C, react for 5h, and keep the pH value of the system at 9. After the reaction, first evaporate the water to dryness, add methanol and filter to remove the inorganic salt, and distill the filtrate to remove the solvent to obtain the crude product. Then use the mixed solution of ethyl acetate and acetone with a mass fraction ratio of 7:3 to repeatedly recrystallize several times, and the solid product is cocamide hydroxypropyl sulfobetaine.

[0047] The second step: add 115.19 parts of cocamide hydroxypropyl sulfobetaine and 80 parts of ethylene glycol monomethyl ether into the reaction bottle, mix well, add 12 parts of 50% KOH solution, and th...

PUM

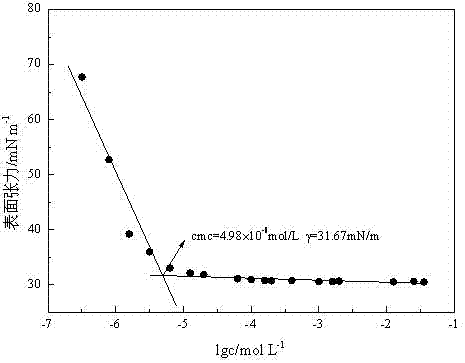

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com