Recovery method of copper indium gallium diselenide material

A copper indium gallium selenide and recovery method technology, which is applied in chemical instruments and methods, gallium/indium/thallium compounds, copper sulfate, etc., can solve problems such as high production costs, lower gallium recovery rate, and large oxidant consumption, and achieve reduction Good volatilization and separation of acid gas, high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

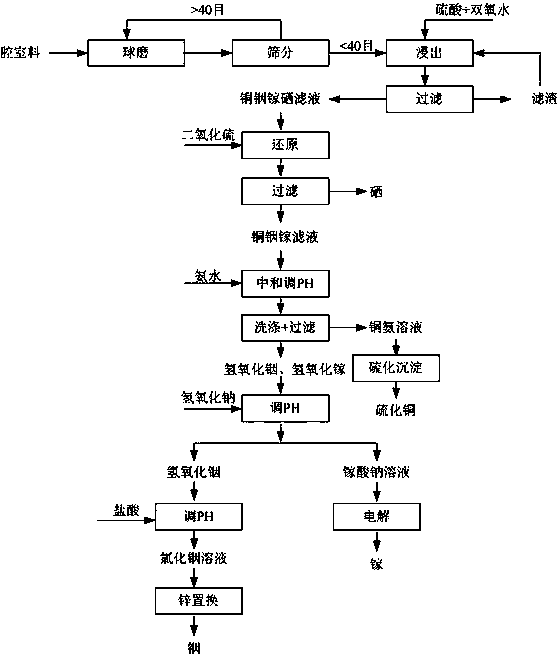

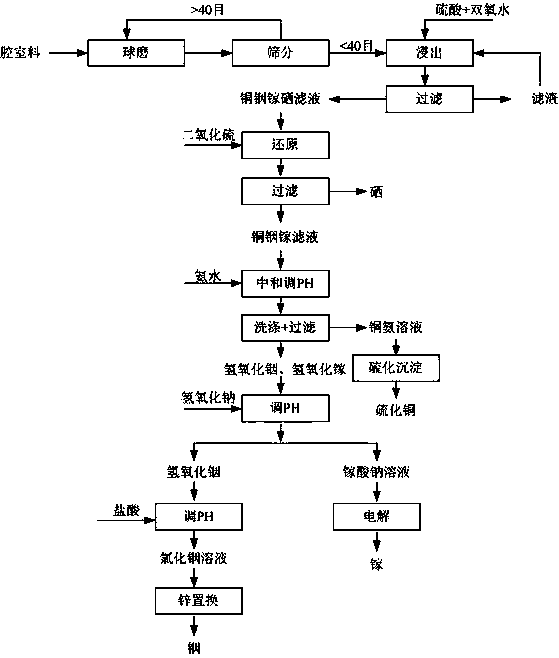

[0042] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] Such as figure 1 As shown, the recovery method of the copper indium gallium selenide material of the present invention mainly includes the following steps:

[0044] In step A, 200 g of copper indium gallium selenide material is placed in a ball mill, ball milled to a powder below 40 mesh, and dried at 100° C. for 4 hours.

[0045] Step B, dilute concentrated sulfuric acid to 25%, mix 200g of drying material with 25% concentrated sulfuric acid at a solid-to-liquid ratio of 1:5, raise the temperature to 90°C, and feed hydrogen peroxide at a rate of 8ml / min, with a stirring rate of 600r / min, leaching at constant temperature for 3 hours, and filtering out the residue after leaching to obtain a pure leaching solution.

[0046] Step C: After raising the temperature of the leaching solution to 65°C, feed sulfur dioxide gas at a rate of 10L / min and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com