Metal base material coated with carbide coating and preparing method of metal base material

A metal-based, carbide-based technology, applied in coatings, solid-state diffusion coatings, metal material coating processes, etc., can solve the problems of inability to obtain uniform coatings, corrosion of equipment by the medium, and weak bonding force of coatings, etc., to achieve broadening Industrial application range, improvement of surface properties, effect of stabilization of salt bath components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

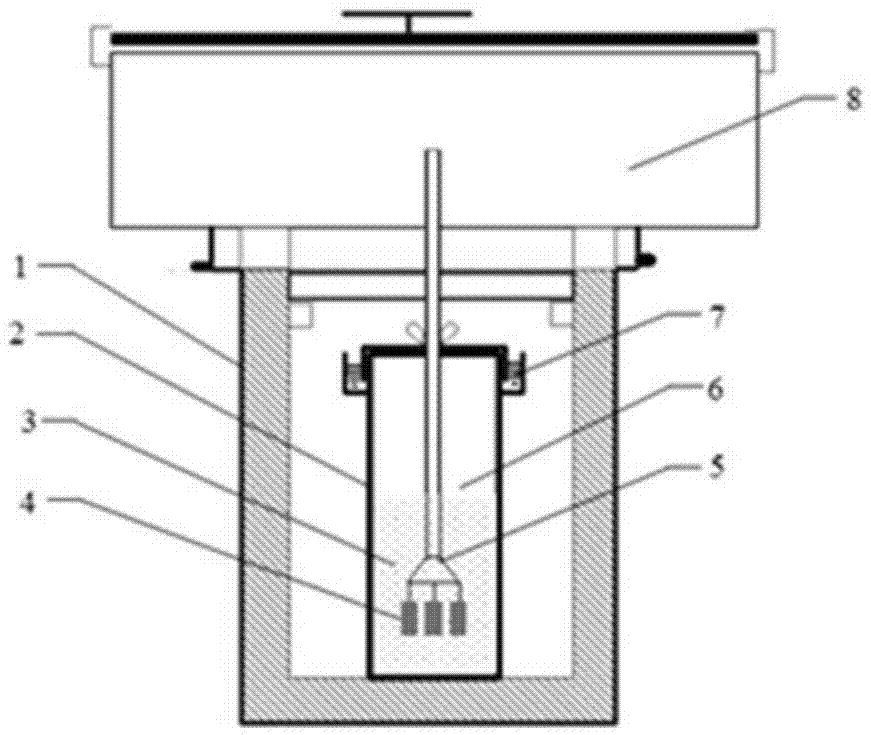

[0046] figure 1 It is a schematic diagram of an experimental device for in-situ preparation of a carbide coating on the surface of a metal-based material in the present invention; wherein, 1 is a heat preservation furnace body; 2 is a container crucible; 3 is a molten salt; 4 is a metal-based material; 5 is a metal-based material fixing fixture ; 6 is an inert atmosphere or vacuum; 7 is a sealed crucible cover; 8 is a closed system device.

[0047] Gray iron coated with vanadium carbide is prepared as follows:

[0048] (1) The gray iron material is cut into a sample of appropriate size by wire electric discharge, and then the surface is pre-ground and polished with metallographic sandpaper until the surface is flat and approximately mirror-like; the pre-ground gray iron sample is washed with absolute ethanol Dry with cold air after washing;

[0049] (2) First, clean the 316L stainless steel crucible with tap water, then clean it with absolute ethanol, dry it with cold air, a...

Embodiment 2

[0057] The preparation process of the gray iron covered with chromium carbide coating adopts as in embodiment 1 figure 1 experimental device.

[0058] Gray iron coated with chromium carbide is prepared as follows:

[0059] (1) The gray iron material is cut into a sample of appropriate size by wire electric discharge, and then the surface is pre-ground and polished with metallographic sandpaper until the surface is flat and approximately mirror-like; the pre-ground gray iron sample is washed with absolute ethanol Wash and dry with cold air;

[0060] (2) First, clean the 316L stainless steel crucible with tap water, then clean it with absolute ethanol, dry it with cold wind, and dehydrate it in a vacuum drying oven at 120°C for about 2 hours;

[0061] (3) Mix the fluoride mixed eutectic molten salt LiF-NaF-KF (molar ratio is 46.5:11.5:42), break it into small particles of suitable size, and put it into a 316L stainless steel crucible; wherein, the amount of solid salt added is...

Embodiment 3

[0068] The preparation process of the gray iron covered with chromium carbide coating adopts as in embodiment 1 figure 1 experimental device.

[0069] Gray iron coated with chromium carbide is prepared as follows:

[0070] (1) The gray iron material is cut into a sample of appropriate size by wire electric discharge, and then the surface is pre-ground and polished with metallographic sandpaper until the surface is flat and approximately mirror-like; the pre-ground gray iron sample is washed with absolute ethanol Wash and dry with cold air;

[0071] (2) First, clean the 316L stainless steel crucible with tap water, then clean it with absolute ethanol, dry it with cold wind, and dehydrate it in a vacuum drying oven at 120°C for about 2 hours;

[0072] (3) Mix the fluoride mixed eutectic molten salt LiF-NaF-KF (molar ratio is 46.5:11.5:42), break it into small particles of suitable size, and put it into a 316L stainless steel crucible; wherein, the amount of solid salt added is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com