Nano composite moisture-permeable film and preparation method and application thereof

A nano-composite, moisture-permeable membrane technology, applied in nanotechnology, nanotechnology, semi-permeable membrane separation and other directions, can solve the problems of high cost, poor dispersion performance, easy to agglomerate, etc. Low-cost, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

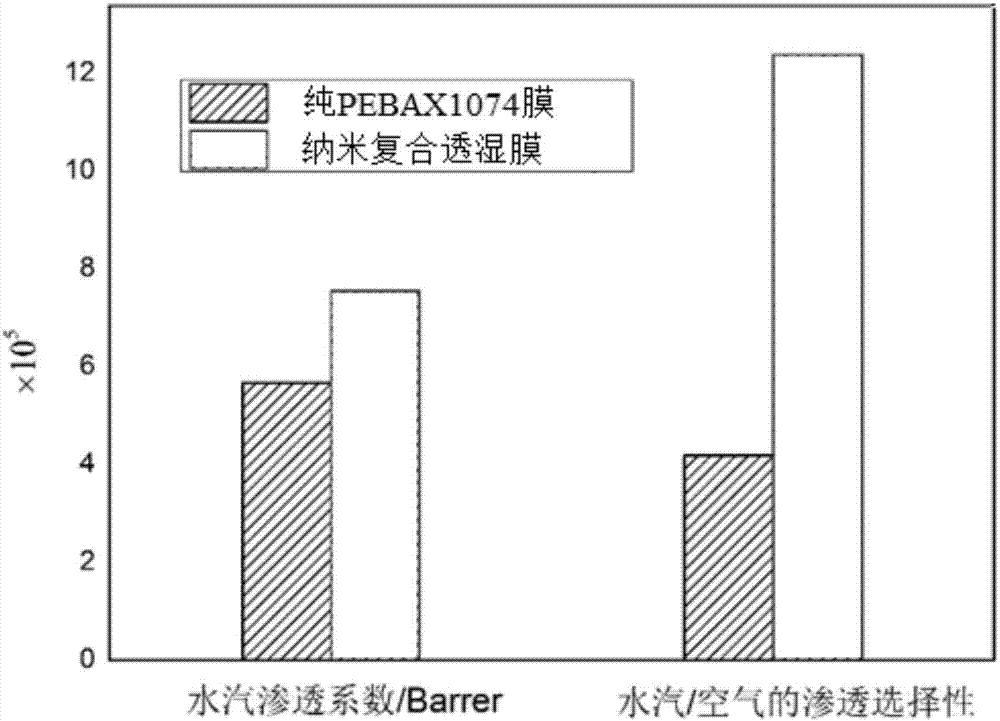

[0041] A nanocomposite moisture-permeable membrane is prepared from the following components and contents in parts by weight:

[0042]

[0043] Concrete preparation process is as follows:

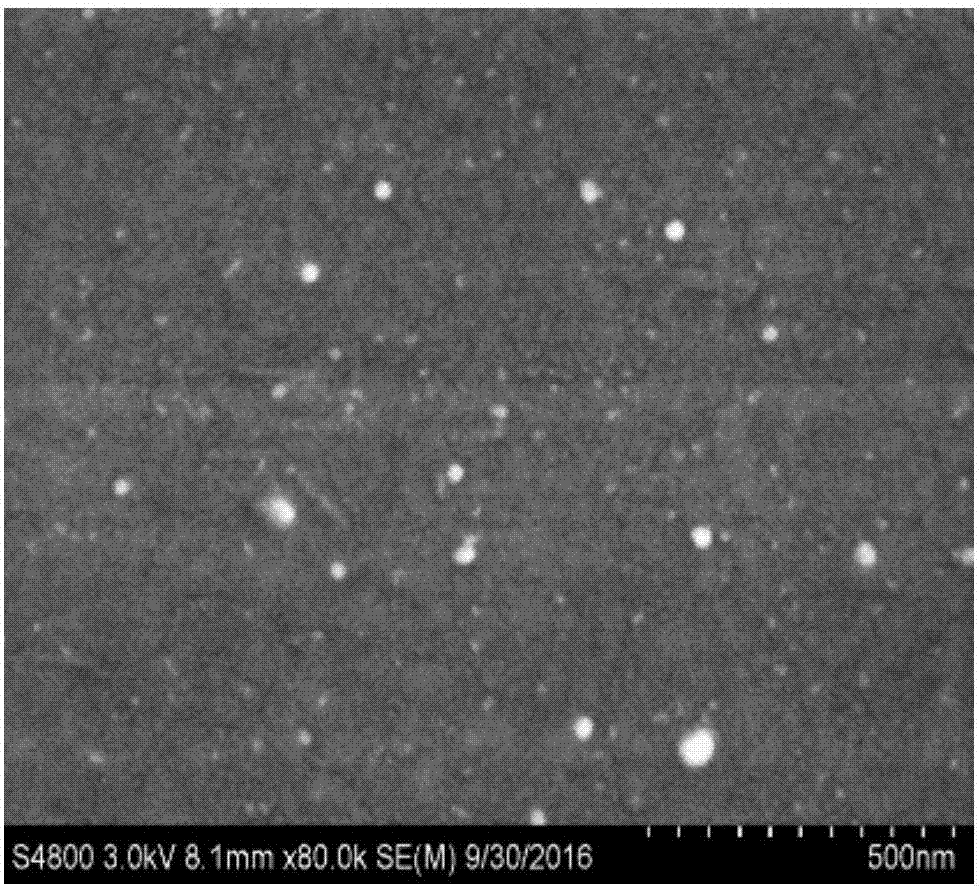

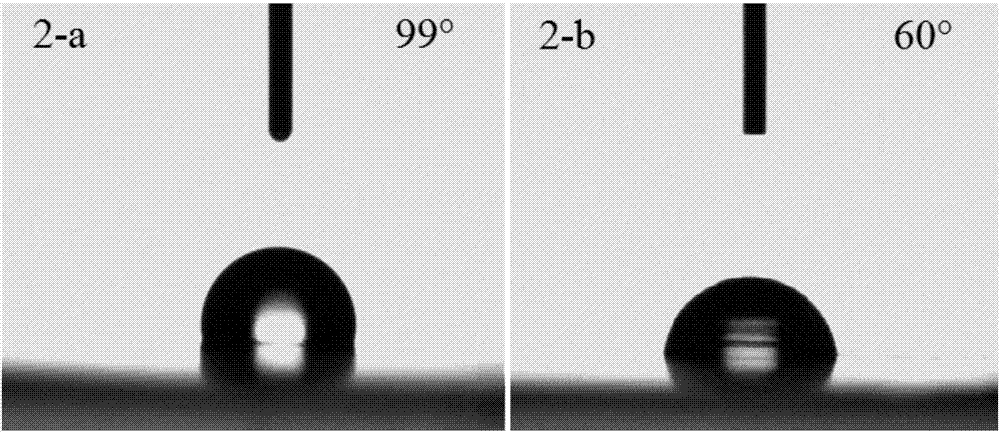

[0044] 1. Preparation of nanocellulose: Add 28g of micron cellulose to 300mL of sulfuric acid solution with a mass fraction of 64%, and stir until no lumps are formed; stir at 44°C for 1.5h; dilute with distilled water and centrifuge to remove the supernatant , repeated dilution and centrifugation until the upper layer became turbid, and collected the turbid liquid containing nanocellulose in the upper layer; dialyzed until pH = 7, and freeze-dried.

[0045] 2. Modification of nanocellulose: Dry the prepared nanocellulose in a vacuum oven at 80°C for 12 hours, then disperse it in a mixture of ethanol and water (ethanol:water=9:1), and add a mass fraction of 1 % KH550, then stirred at 60°C for 9h, washed repeatedly with deionized water and ethanol three times, and then dried in a vacuum ...

Embodiment 2

[0054] A nanocomposite moisture-permeable membrane is prepared from the following components and contents in parts by weight:

[0055]

[0056] Concrete preparation process is as follows:

[0057] 1. Modification of nano-potassium titanate whiskers: dry the nano-potassium titanate whiskers in a vacuum oven at 80°C for 24 hours, then slowly add them to an aqueous solution with a KH550 content of 1%, and slowly stir at 30°C for several minutes , and then heated to 80°C, stirred for 12h, washed with deionized water, and then dried at 110°C for 12h.

[0058] 2. Preparation of nano-potassium titanate whiskers / cross-linked polyvinyl alcohol composite film: dissolve 0.5g polyvinyl alcohol in 25mL deionized water at 95°C, let stand overnight for defoaming; slowly add 0.57g of supernatant ammonium sulfate and 0.38g of N,N-methylenebisacrylamide, and stir evenly, then add the modified nano-potassium titanate whiskers with a mass fraction of 10%, and ultrasonically disperse to prepar...

Embodiment 3

[0060] A nanocomposite moisture-permeable membrane is prepared from the following components and contents in parts by weight:

[0061]

[0062] 1. Modification of nano-calcium sulfate whiskers: dry nano-calcium sulfate whiskers in a vacuum oven at 80°C for 24 hours, then disperse them in ethanol, add stearic acid with a mass fraction of 1.5%, and stir at 90°C for 30 minutes, Then wash with absolute ethanol, and then dry at 110°C.

[0063] 2. Preparation of sulfonated polybenzimidazole: Add 170g of solvent polyphosphoric acid into a dry 250mL three-necked flask, and then add 5g of water-absorbing agent P 2 o 5 . Assemble the device, ventilate with nitrogen, turn on the mechanical stirring, and at the same time raise the temperature to 120°C to remove all the air in the three-necked flask. Keep warm for 90min, wait for P 2 o 5 After completely dissolving in polyphosphoric acid, accurately weigh 13mmol (2.8136g) of 3,3',4,4'-biphenyltetramine and 13mmol (3.5574g) of 2-sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com