Preparation method of magnetic nanometer catalyst

A magnetic nano-catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult catalyst recycling, achieve difficult recovery, mild preparation conditions, and improve catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

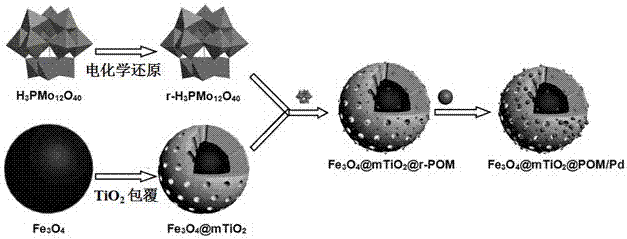

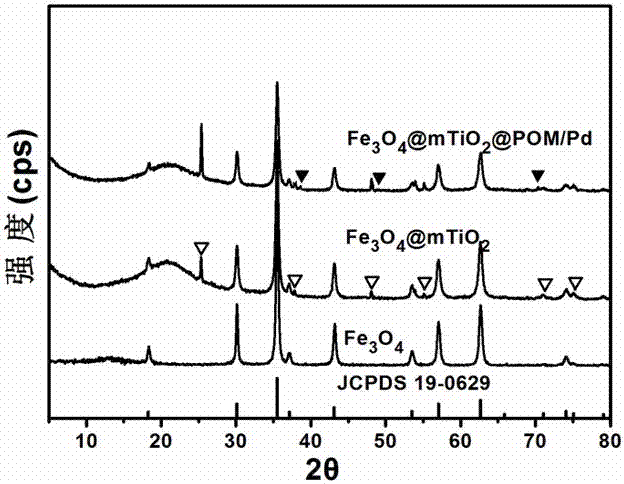

[0028] Example 1 Mesoporous TiO 2 coated magnetic Fe 3 o 4 Synthesis of microparticles

[0029] Reference [J. Mater. Chem. A, 2015, 3, 6492–6500] to prepare Fe 3 o 4 Magnetic particles: Ferric chloride (2.70 g), polyethylene glycol (3.00 g) and anhydrous sodium acetate (7.20 g) were dissolved in ethylene glycol (80 mL), heated and stirred until homogeneous, then transferred to polytetrafluoroethylene An ethylene-lined stainless steel autoclave (100 mL) was maintained at 200 °C for 8 h. A magnet collects the product after completion.

[0030] Fe 3 o 4 @mTiO 2 Magnetic core-shell preparation: Fe 3 o 4 (0.15g) was dispersed in ethanol (90ml), added ammonia water (0.4ml) to adjust to alkalinity, added ethanol solution of tetrabutyl titanate (0.75g dissolved in 10ml), stirred at 45°C for 24h, separated by magnet and Disperse in water (50ml), ultrasonicate at 20°C for 4 hours under reflux at a constant temperature, wash with ethanol after magnetic separation, and dry at r...

Embodiment 2

[0031] The electrochemical reduction of embodiment 2 phosphomolybdic acid

[0032] Phosphomolybdic acid H 3 PMo 12 o 40 Configured as a 10mM solution, put a DC power supply in the electrolytic cell, and electrolyze for 6h under the condition of (5V, 10mA), the polyacid solution gradually turns blue and is sealed and stored, recorded as r-H 3 PMo 12 o 40 .

Embodiment 3

[0033] Example 3 Loading of reduced polyacid on magnetic carrier

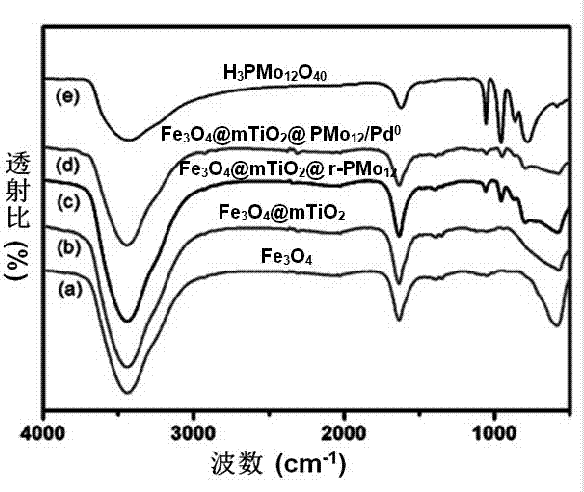

[0034] Take 0.1g Fe 3 o 4 @mTiO 2 Add 100ml r-H 3 PMo 12 o 40 , stirred at room temperature for 12 h, separated the obtained magnetic nanoparticles with a magnet, washed and dried. Such as figure 2 As shown, the characteristic peak of phosphomolybdic acid appeared on the curve (d), indicating that the polyacid was successfully loaded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com