Fe(III)-Salen functionalized nano Fe3O4 composite material as well as preparation method and application thereof

A composite material and magnetic composite material technology, applied in Fe(III)‑Salen functionalized nano Fe3O4 composite material, preparation and application fields, can solve the problems of easy oxidative decomposition, TAML instability, etc., and achieve a wide range of pH application , Conducive to separation and recovery, the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

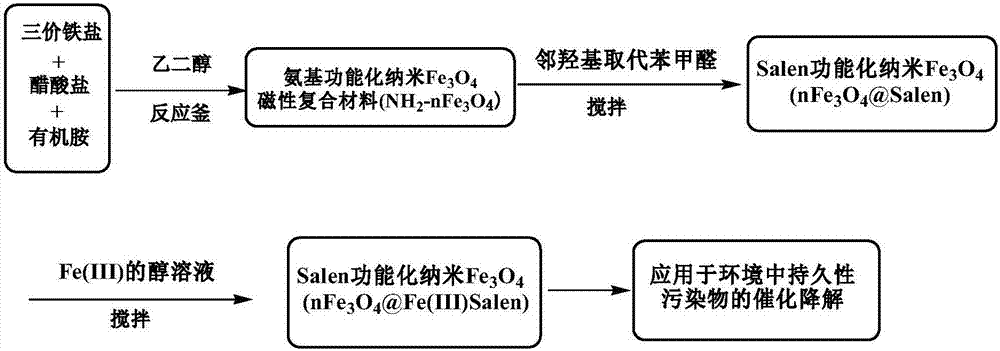

Method used

Image

Examples

Embodiment 1

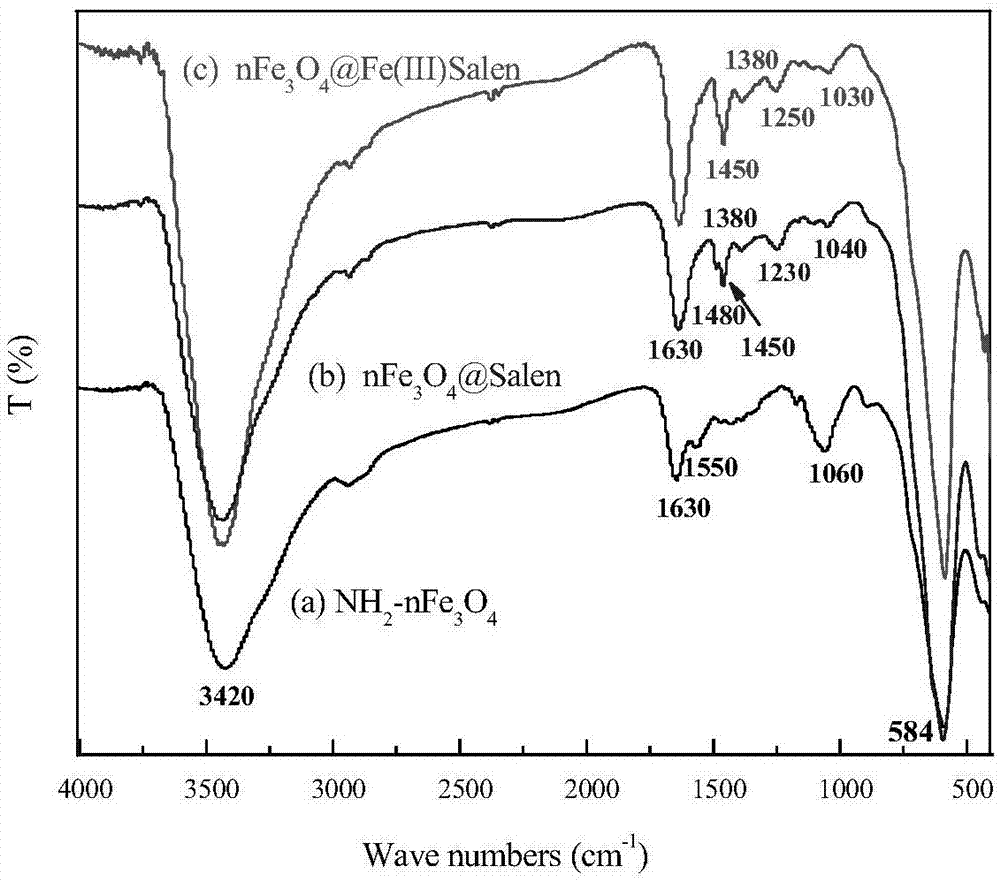

[0039] Weigh FeCl separately 3 ·6H 2 O and anhydrous sodium acetate were dissolved in ethylene glycol and stirred at room temperature for 10 min. Then ethylenediamine was added and stirred until a stable orange solution was formed. The reaction solution was transferred to a reaction kettle, and reacted at 180°C for 8h. After cooling, magnetically separated, washed with deionized water and ethanol three times each, until the pH value was 7, and vacuum-dried at 60°C for 12h to obtain NH 2 -nFe 3 o 4 .

[0040] Using methanol as solvent, add NH 2 -nFe 3 o 4 , ultrasonically disperse, add salicylaldehyde dropwise under stirring, react at room temperature for 2 h, magnetically separate, wash with deionized water and ethanol three times successively, until the pH value is 7, and vacuum dry at 60 °C for 12 h to obtain Salen functionalized nano-Fe 3 o 4 (nFe 3 o 4 @Salen).

[0041] nFe 3 o 4 @Salen is added to the methanol solution, ultrasonically dispersed, and slowly ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com