Coating method and device for solid medium layer inside coke oven ascension pipe crude gas waste heat recovery heat exchanger

A technology of waste heat recovery and solid medium, which is applied to the heating of coke ovens, the discharge device of dry distillation gas, and the device for coating liquid on the surface, etc. Excellent, uneven coating and other problems, to achieve the effect of reducing coating cost, ensuring coating quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

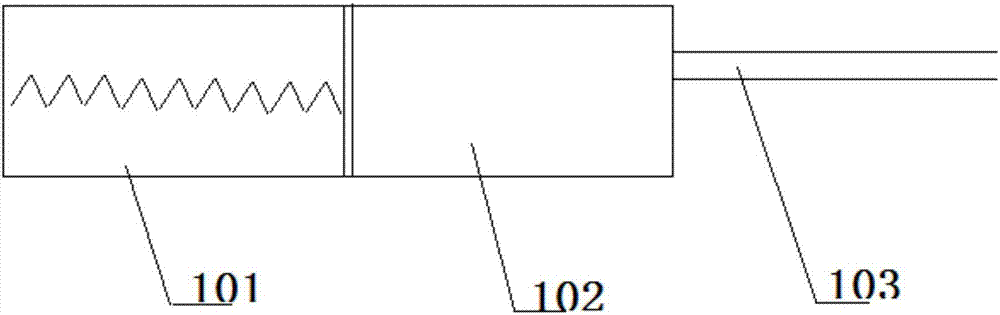

[0018] The press used for coating the solid medium layer in the waste heat recovery heat exchanger of the coke oven riser tube includes a pressurizing device 101 , a pressure vessel 102 and an ejection pipe 103 connected in sequence.

Embodiment 2

[0020] The method for coating the solid medium layer in the coke oven ascending tube raw gas waste heat recovery heat exchanger includes the following steps:

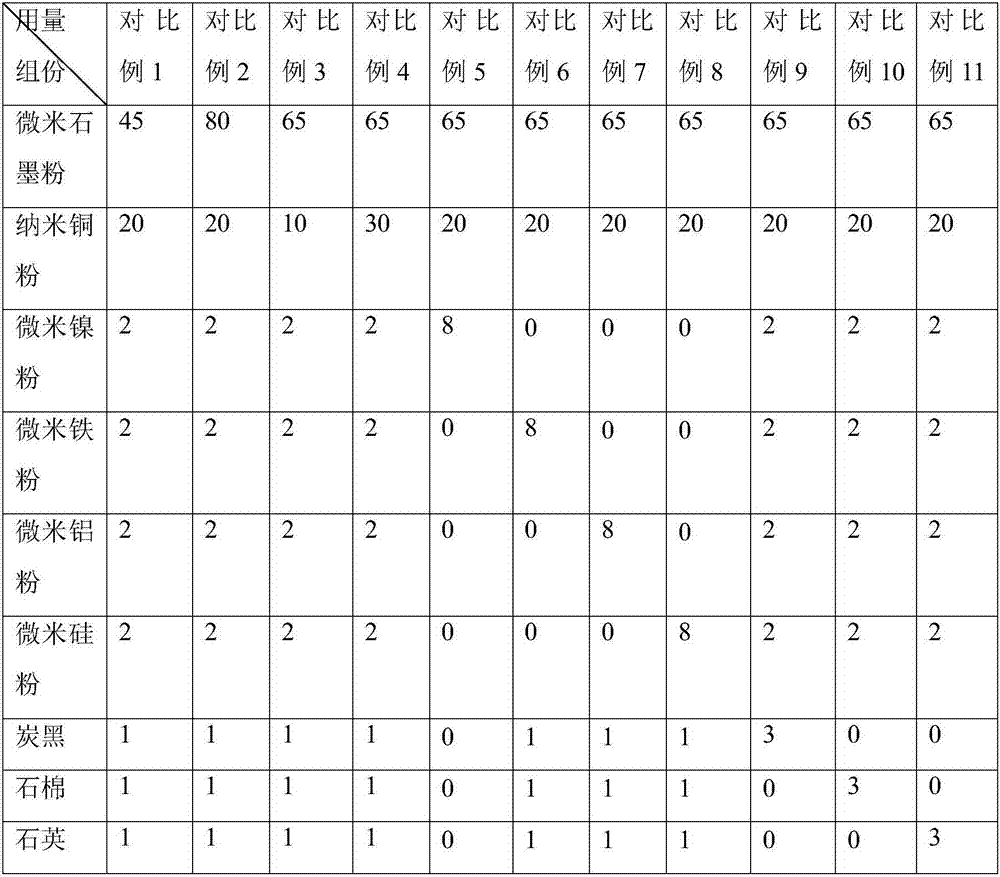

[0021] (1.1) Mix solid powder with high thermal conductivity and high temperature resistant glue to obtain wet material; solid powder with high thermal conductivity includes 65 parts of micron graphite powder, 20 parts of nanometer copper powder, 2 parts of micron nickel powder, and 2 parts of micron iron powder , 2 parts of micron aluminum powder, 2 parts of micron silicon powder, 1 part of carbon black, 1 part of asbestos, 1 part of quartz, in parts by weight; the high temperature resistant glue is a high-strength structural glue with a temperature resistance above 900 ° C; high thermal conductivity The mass ratio of solid powder and high temperature resistant glue is 4:1;

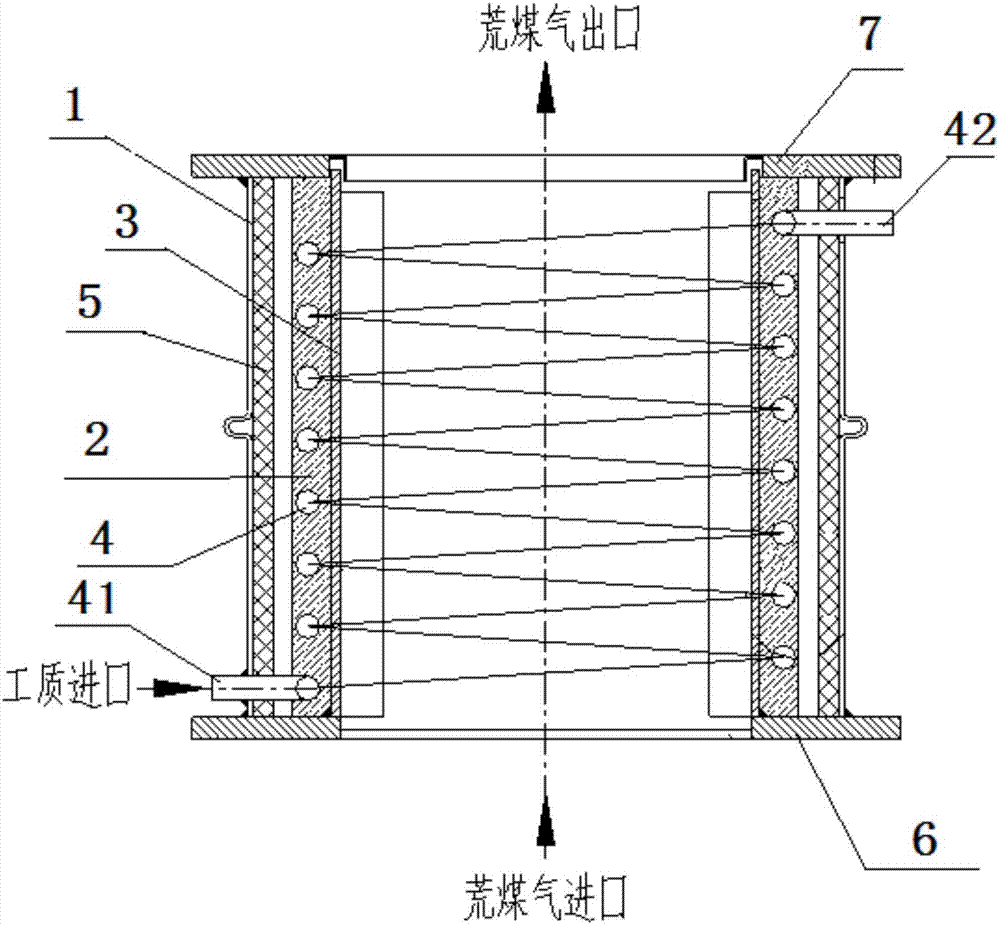

[0022] (1.2) Fill the inner wall of the outer cylinder layer 1 with a flexible insulation layer 5; install the inner cylinder layer 3 on the lowe...

Embodiment 3

[0026] The method for coating the solid medium layer in the coke oven ascending tube raw gas waste heat recovery heat exchanger includes the following steps:

[0027] (1.1) Mix solid powder with high thermal conductivity and high temperature resistant glue to obtain wet material; solid powder with high thermal conductivity includes 50 parts of micron graphite powder, 25 parts of nanometer copper powder, 1 part of micron nickel powder, and 1 part of micron iron powder , 1 part of micron aluminum powder, 3 parts of micron silicon powder, 0.5 part of carbon black, 1.5 part of asbestos, 0.5 part of quartz, in parts by weight; the high temperature resistant glue is a high strength structural glue with a temperature resistance above 900 ° C; high thermal conductivity The mass ratio of solid powder and high temperature resistant glue is 3:1;

[0028] (1.2) Fill the inner wall of the outer cylinder layer 1 with a flexible insulation layer 5; install the inner cylinder layer 3 on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com