Pentafluorophenol preparation mehtod

A technology for pentafluorophenol and preparation steps, applied in the field of preparation of pentafluorophenol, can solve the problems of difficulty in meeting the requirements for preparing high-quality liquid crystal materials and medicines, difficulty in separation, high production cost, complicated refining process of pentafluorophenol, etc. Stable, avoid side reactions, reduce the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

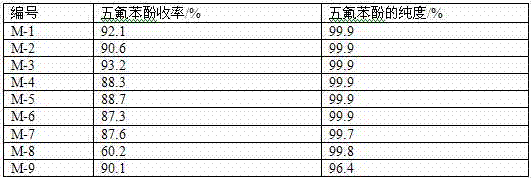

Examples

Embodiment 1

[0022] 1. Preparation of hydrolysis catalyst:

[0023] (1) Preparing the precursor: by weight, put 100 parts of sodium aluminate in an air atmosphere at 400 ° C for 3 hours; then add 3 parts of potassium fluoride, 0.03 parts of 10-(2,5-dihydroxyphenyl )-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide, 0.2 parts of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene, 5 parts of anhydrous trichloride Iron, 20 parts of sodium metasilicate pentahydrate, stir evenly, control the stirring speed to 110r / min, then leave for 5h to obtain the precursor;

[0024] (2) Drying and calcination: move the precursor to an oven, dry it at 105°C for 14 hours, grind it, and finally bake it in an air atmosphere at 400°C for 4 hours to obtain a hydrolysis catalyst;

[0025] 2. Preparation of pentafluorophenol

[0026] In parts by weight, add 700 parts of water, 75 parts of sodium hydroxide, 7 parts of hydrolysis catalyst, 100 parts of hexafluorobenzene, 0.5 part of didodecyl secondary amine into the autocla...

Embodiment 2

[0030] 1. Preparation of hydrolysis catalyst:

[0031] (1) Preparation of the precursor: by weight, put 100 parts of sodium aluminate in an air atmosphere at 200°C for 6 hours; then add 1 part of potassium fluoride, 0.01 part of 10-(2,5-dihydroxyphenyl )-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide, 0.1 part of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene, 1 part of anhydrous trichloride Iron, 10 parts of sodium metasilicate pentahydrate, stir evenly, control the stirring speed to 100 r / min, then leave for 3 hours to obtain the precursor;

[0032] (2) Drying and calcination: move the precursor to an oven, dry it at 100°C for 24 hours, grind it, and finally bake it in an air atmosphere at 200°C for 6 hours to obtain a hydrolysis catalyst;

[0033] 2. Preparation of pentafluorophenol

[0034] In parts by weight, add 500 parts of water, 50 parts of sodium hydroxide, 3 parts of hydrolysis catalyst, 100 parts of hexafluorobenzene, 0.1 part of didodecyl secondary amine into the au...

Embodiment 3

[0038] 1. Preparation of hydrolysis catalyst:

[0039] (1) Preparation of the precursor: by weight, put 100 parts of sodium aluminate in an air atmosphere at 600 ° C for 2 hours; then add 10 parts of potassium fluoride, 0.1 part of 10-(2,5-dihydroxyphenyl )-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide, 1 part of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene, 10 parts of anhydrous trichloride Iron, 30 parts of sodium metasilicate pentahydrate, stir evenly, control the stirring speed to 120r / min, then leave for 10h to obtain the precursor;

[0040] (2) Drying and roasting: move the precursor to an oven, dry at 130°C for 12 hours, grind, and finally roast at 600°C in an air atmosphere for 2 hours to obtain a hydrolysis catalyst;

[0041] 2. Preparation of pentafluorophenol

[0042] In parts by weight, add 1000 parts of water, 100 parts of sodium hydroxide, 10 parts of hydrolysis catalyst, 100 parts of hexafluorobenzene, 1 part of didodecanyl secondary amine into the autoclave, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com