A red long afterglow luminescent material and preparation method thereof

A long afterglow luminescence, red technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that do not meet the practical requirements, the excitation intensity in the visible light region needs to be improved, and the afterglow time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a) Weighing calcium carbonate, tin dioxide and europium oxide in the stoichiometric molar ratio Ca:Sn:Eu=2:1:0.01, relative to the matrix CaSnO 3 The add-on is 20mol% to take by weighing boric acid;

[0037] b) adding water to the mixture in step a), the amount of water is 2 times the weight of the mixture, and the wet blending and grinding are performed for 1 h;

[0038] c) drying the uniformly mixed raw materials after grinding in step b), the drying temperature is 150°C, and the drying time is 2h;

[0039] d) grinding the dried raw material in step c) into powder, using pulverized coal as a reducing agent, and carrying out a high-temperature solid-phase reaction in a weak reducing atmosphere, the calcination temperature is 1300 ° C, and the holding time is 1 h;

[0040] e) taking out the calcined sample in step d) and grinding to obtain a red long afterglow luminescent material.

Embodiment 2

[0042] a) Weigh calcium carbonate, tin dioxide, europium oxide and sublimed sulfur in a stoichiometric molar ratio Ca:Sn:Eu:S=2:1:0.004:0.01;

[0043] b) adding water to the mixture in step a), the amount of water is 3 times the weight of the mixture, and the wet blending and grinding are performed for 2h;

[0044] c) drying the uniformly mixed raw materials after grinding in step b), the drying temperature is 200°C, and the drying time is 1h;

[0045] d) grinding the dried raw materials in step c) into powder, using activated carbon as a reducing agent, and performing a high-temperature solid-phase reaction in a weak reducing atmosphere, the calcination temperature is 1350°C, and the holding time is 0.5h;

[0046] e) taking out the calcined sample in step d) and grinding to obtain a red long afterglow luminescent material.

Embodiment 3

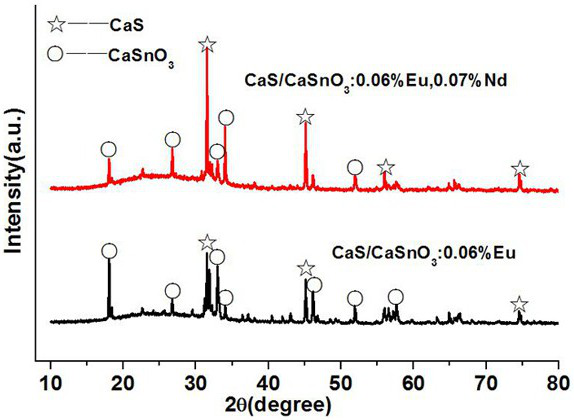

[0048] a) Ca:Sn:Eu:Nd:S=2:1:0.0006:0.0007:0.05 in stoichiometric molar ratio weighing calcium carbonate, tin dioxide, europium oxide, neodymium oxide and sublimed sulfur relative to the matrix CaSnO 3 The add-on is 30mol% to take by weighing boric acid;

[0049] b) adding ethanol to the mixture in step a), the amount of ethanol is 1 times the weight of the mixture, and wet blending and grinding for 2h;

[0050] c) drying the uniformly mixed raw materials after grinding in step b), the drying temperature is 60°C, and the drying time is 6h;

[0051] d) grinding the dried raw materials in step c) into powder, and using an atmosphere furnace to create a weak reducing atmosphere for high-temperature solid-phase reaction, the volume ratio of hydrogen to nitrogen is 10:90, the calcination temperature is 900°C, and the holding time is 8h;

[0052] e) taking out the calcined sample in step d) and grinding to obtain a red long afterglow luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com