Mesoporous beta zeolite and preparation method thereof

A beta zeolite and mesoporous technology, applied in the field of mesoporous beta zeolite and its preparation, can solve the problems of high preparation cost and improved molecular diffusivity of mesoporous zeolite, and achieve the advantages of reduced preparation cost, large volume, and simple and economical preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

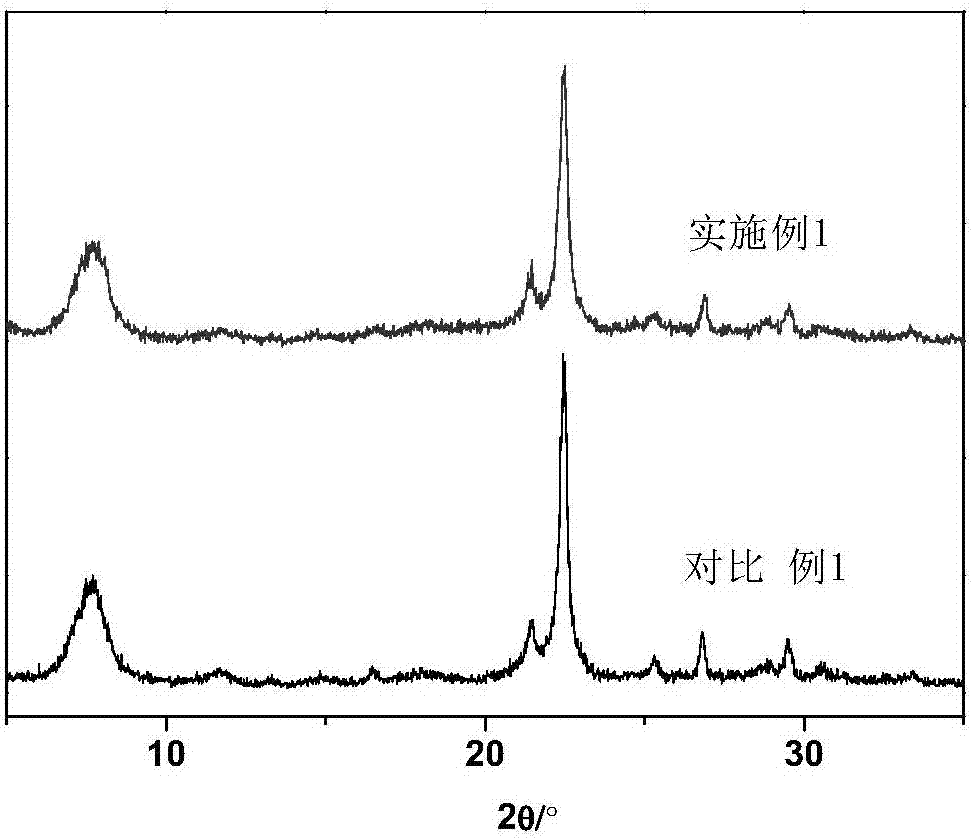

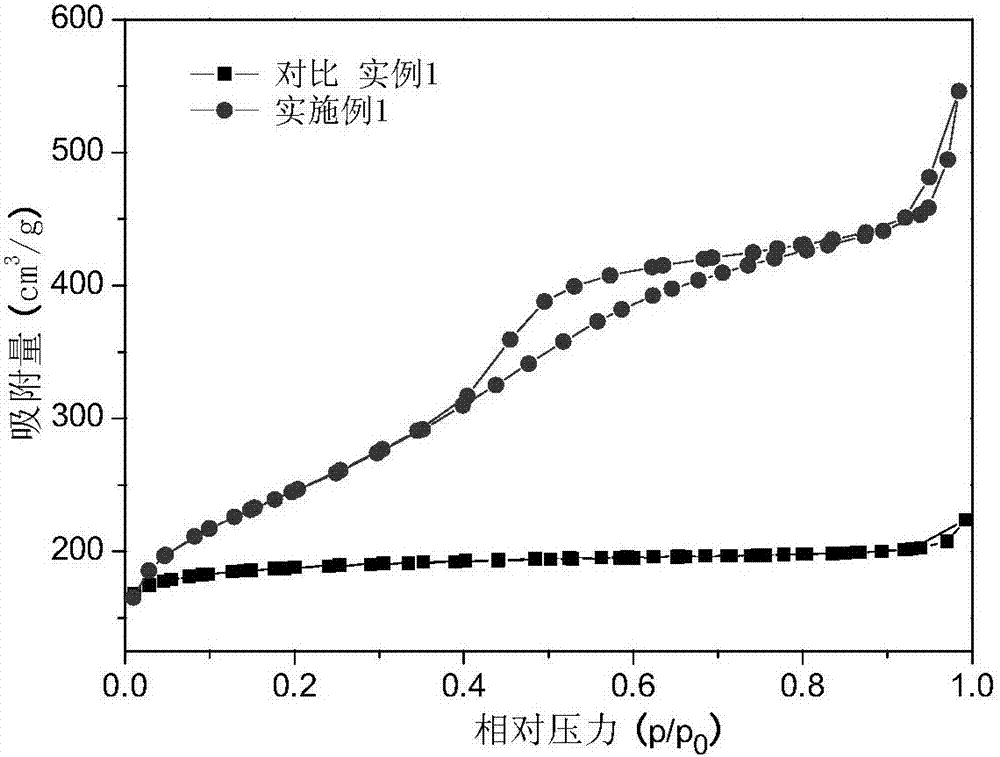

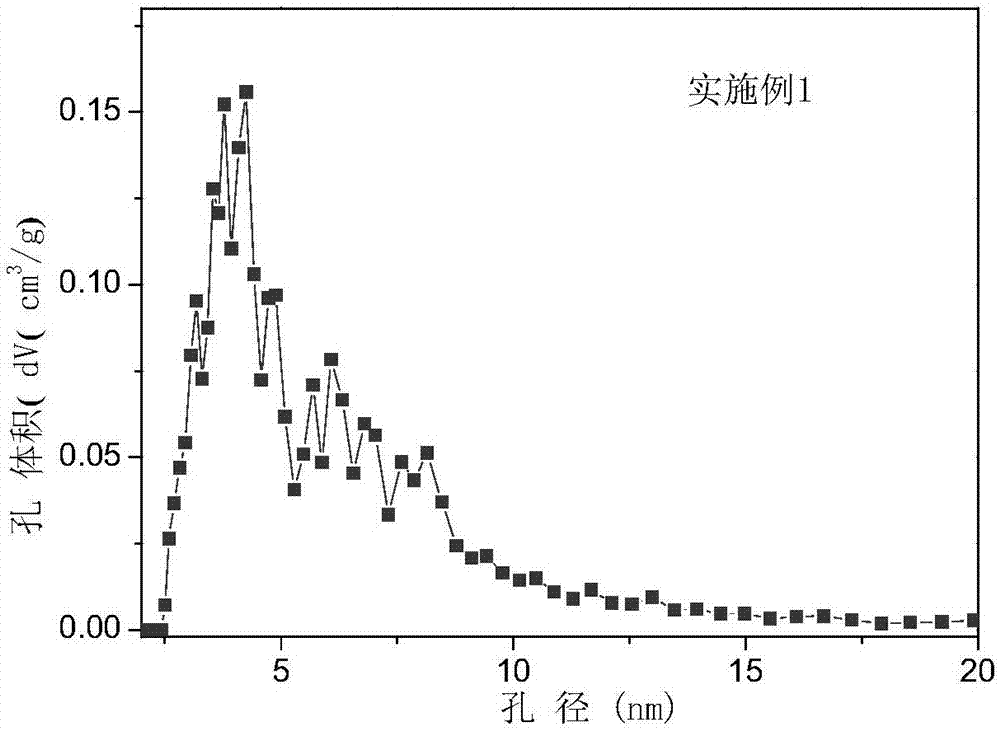

Embodiment 1

[0030] Take by weighing 8.4g tetraethylammonium bromide (technical grade 98wt%), 0.8g sodium hydroxide 96wt%, 0.43g pseudo-boehmite (70wt%, technical grade), 0.3g squid powder, 20g water, 1g Dehydrated alcohol (99.5%) was mixed and stirred to a clear solution, then 7.2g of white carbon black (technical grade 98wt%) was added to the solution under constant stirring, and continued stirring to obtain a uniform silica-alumina gel; The gel was dynamically crystallized at 140°C for 10 days, and after solid-liquid separation, washing and drying, it was calcined at 550°C for 8 hours in an air stream to obtain a mesoporous Beta zeolite molecular sieve.

Embodiment 2

[0035] Take by weighing 8.4g tetraethylammonium bromide (technical grade 98wt%), 0.53g sodium hydroxide 96wt%, 0.43g pseudo-boehmite (70wt%, technical grade), 0.2g squid powder, 30g orthosilicic acid Ethyl ester (technical grade SiO 2 , 28wt%), 1g of absolute ethanol (99.5%), mixed and stirred to obtain a uniform silica-alumina gel, and the silica-alumina gel was dynamically crystallized at 140 ° C for 10 days, after solid-liquid separation and washing and drying, in the air flow Calcined at 550°C for 8 hours to obtain Beta zeolite molecular sieve.

[0036]The specific mesoporous structural characteristics of the mesoporous Beta zeolite obtained in Example 2 are shown in Table 1 below.

Embodiment 3

[0038] Take by weighing 9.4g tetraethylammonium bromide (technical grade 98wt%), 0.53g sodium hydroxide 96wt%, 0.75g sodium metaaluminate (41wt%, technical grade), 0.4g squash powder, 30g ethyl orthosilicate Esters (industrial grade SiO 2 , 28wt%), 1g absolute ethanol (99.5%), mixed and stirred to obtain a uniform silica-alumina gel, and continued stirring to obtain a uniform silica-alumina gel; the silica-alumina gel was dynamically crystallized at 145 ° C for 7 days, After solid-liquid separation, washing and drying, it is calcined at 550° C. for 8 hours in an air stream to obtain a Beta zeolite molecular sieve.

[0039] The specific mesoporous structural characteristics of the mesoporous Beta zeolite obtained in Example 3 are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com